Silicon paintable antistatic emulsion with good stability and preparation method thereof

A stable performance, antistatic technology, applied in coatings, conductive coatings, etc., can solve the problems of antistatic performance failure, increase catalyst addition, single function, etc., to improve antistatic performance, enhance electrical conductivity, and ensure peeling. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A silicon-coatable antistatic emulsion with good stability, which consists of: 20 parts of epoxy-containing linear silane coupling agent, 0.05 part of phenylhydroxy reticular silicone resin, conductive polymer poly 5 parts of thiophene, 20 parts of single-armed carbon nanotube aqueous solution, 5 parts of surfactant, and 49.95 parts of water.

[0041] The structural formula of the linear silane coupling agent containing epoxy group is as follows:

[0042]

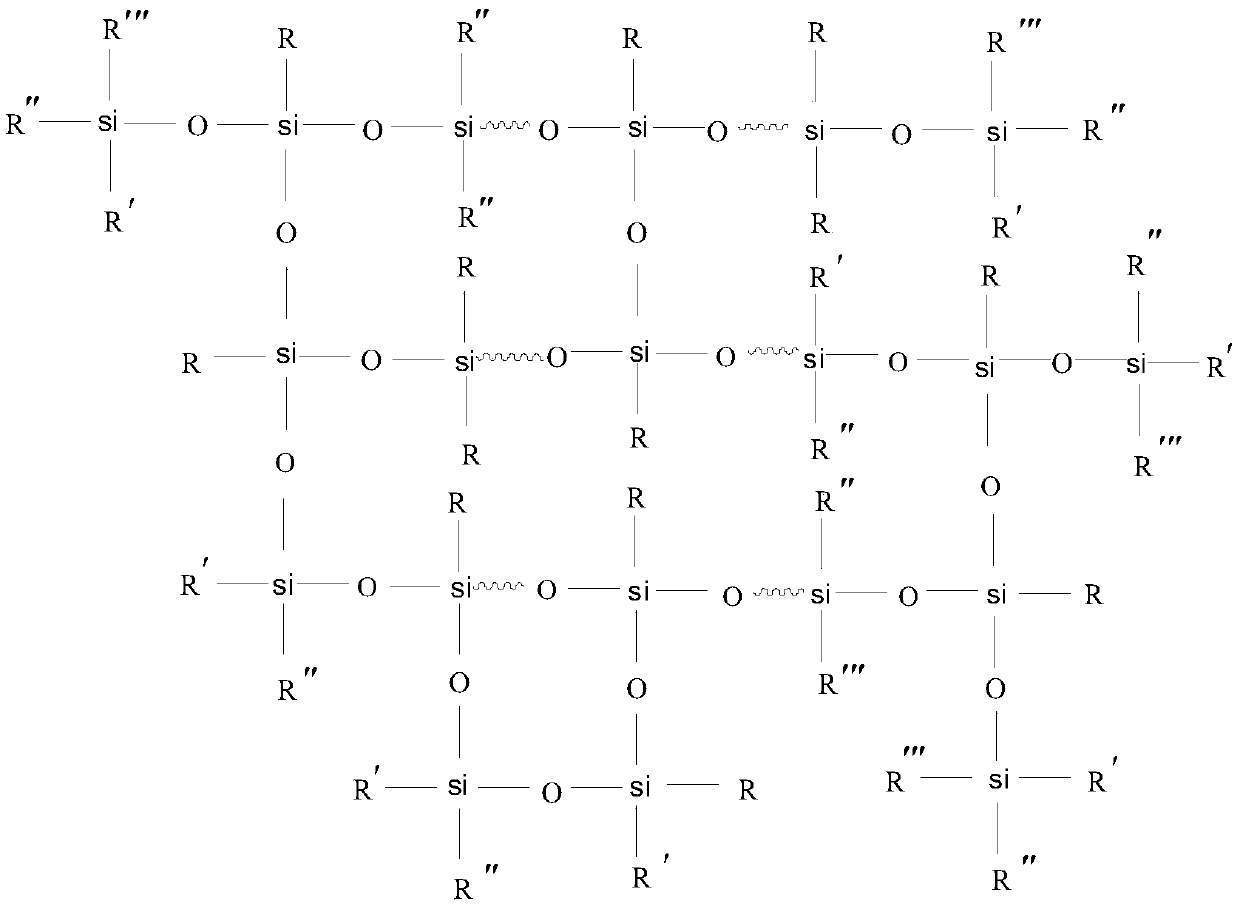

[0043] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0044]

[0045] Wherein, R, R", R"' are the same or different linear or branched aryl groups of 6-20 carbon atoms or aralkyl groups of 7-20 carbon atoms, and R' is a hydroxyl group.

[0046] The preparation method of the phenylhydroxy reticular silicone resin is as follows: respectively add 140 g of distilled water and 1.0 g of hydrochloric acid with a concentration of 1 mol / L in a four-necked flask with stirring, ref...

Embodiment 2

[0055] A silicon-coatable antistatic emulsion with good stability, which consists of: 15 parts of epoxy-containing linear silane coupling agents, 1 part of phenylhydroxy reticular silicone resin, conductive polymer poly 50 parts of thiophene, 0.5 parts of single-arm carbon nanotube aqueous solution, 3.95 parts of surfactant, and 30 parts of water.

[0056] The structural formula of the linear silane coupling agent containing epoxy group is as follows:

[0057]

[0058] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0059]

[0060] Among them, R, R", R"' are the same or different linear or branched aryl groups with 6 to 20 carbon atoms or aralkyl groups with 7 to 20 carbon atoms, and R' is a hydroxyl group;

[0061] The preparation method of the phenyl hydroxy reticular silicone resin is as follows: respectively add 200 g of distilled water and 1.2 g of hydrochloric acid with a concentration of 1 mol / L in a four-necked flask with s...

Embodiment 3

[0070] A silicon-coatable antistatic emulsion with good stability, in parts by weight, consists of: 5 parts of epoxy-containing linear silane coupling agents, 0.8 parts of phenylhydroxy reticular silicone resin, conductive polymer poly 26 parts of thiophene, 12.2 parts of single-armed carbon nanotube aqueous solution, 1 part of surfactant, and 55 parts of water.

[0071] The structural formula of the linear silane coupling agent containing epoxy group is as follows:

[0072]

[0073] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0074]

[0075] Among them, R, R", R"' are the same or different linear or branched aryl groups with 6 to 20 carbon atoms or aralkyl groups with 7 to 20 carbon atoms, and R' is a hydroxyl group;

[0076] The preparation method of described phenyl hydroxy reticular silicone resin is: add 200g distilled water, 1.2g concentration respectively in the four-necked flask that has stirring, reflux condenser, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com