A kind of high viscosity modified asphalt and preparation method thereof

A modified asphalt, high-viscosity technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor temperature stability of asphalt materials, restrictions on the use of asphalt pavement, easy softening, etc. Ensures anti-scattering performance, enhances grip and cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

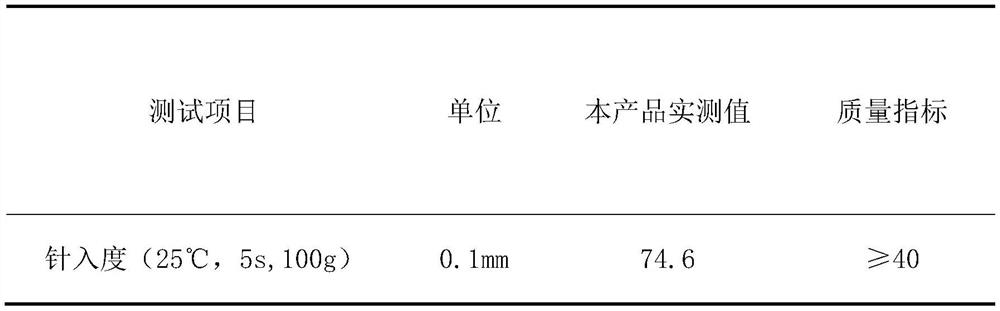

Examples

Embodiment 1

[0033] The modified asphalt formula of this embodiment is as follows: matrix asphalt 5kg, composite reinforcing fiber is formed by compounding 100g basalt fiber and 100g polyester fiber, additives include 50g compatibilizer, 80gSBS, 35gEVA, 1.5g sulfur powder, 120g rubber powder, 50g terpene resin, 60g thermoplastic rubber and 5g Roadmate A series of asphalt anti-stripping agents; the rubber powder includes 49.0wt% rubber hydrocarbon, 11.5wt% acetone extract, 32.0wt% carbon black and 7.5wt% ash.

[0034] The preparation method is as follows:

[0035] (1) Dry the base asphalt to 135°C, and convert the base asphalt into liquid asphalt;

[0036] (2) Spread the basalt fiber and polyester fiber evenly, spray liquid asphalt on the surface and cool it down to below -10°C quickly, so that the fiber surface is evenly wrapped with asphalt film, and flip it quickly during the cooling process to prevent composite reinforcement fibers Adhesion; Then the composite fiber wrapped with asph...

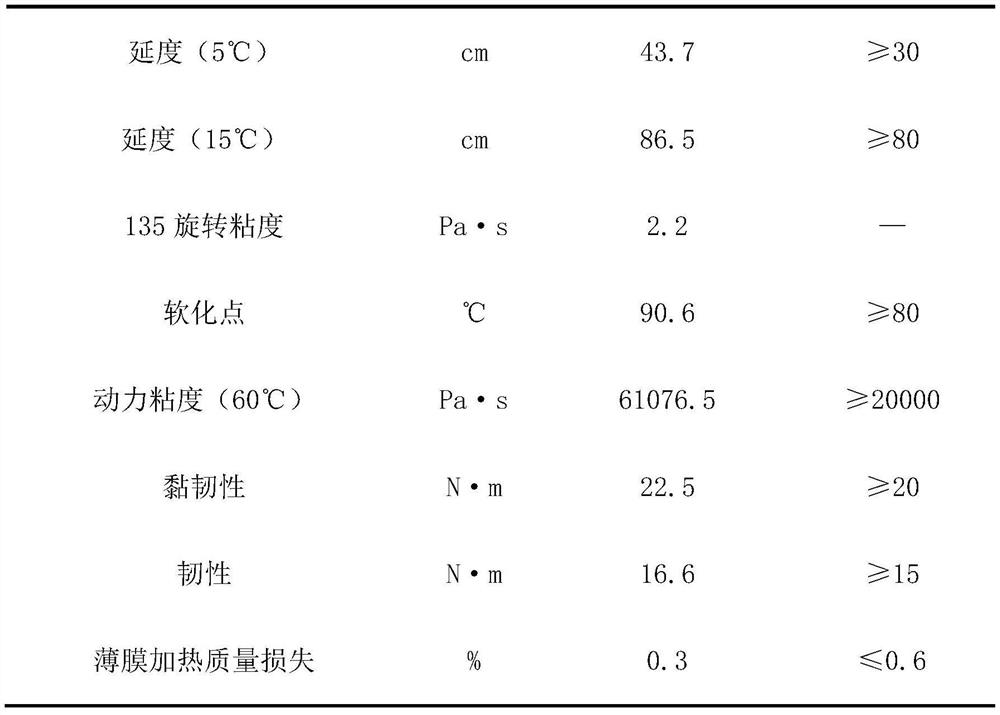

Embodiment 2

[0045]The modified asphalt formula of this embodiment is as follows: matrix asphalt 5kg, composite reinforcing fiber is formed by compounding 50g basalt fiber and 100g polyester fiber, additives include 100g compatibilizer, 50gSBS, 60gEVA, 3.5g sulfur powder, 100g rubber powder, 20g terpene resin, 50g thermoplastic rubber and 2g anti-peeling agent; the rubber powder includes 49.0wt% rubber hydrocarbon, 11.5wt% acetone extract, 32.0wt% carbon black and 7.5wt% ash.

[0046] The preparation method is the same as in Example 1. The modified resin prepared in this example was subjected to a performance test, and the test results are shown in Table 2.

[0047] Table 2

[0048]

[0049]

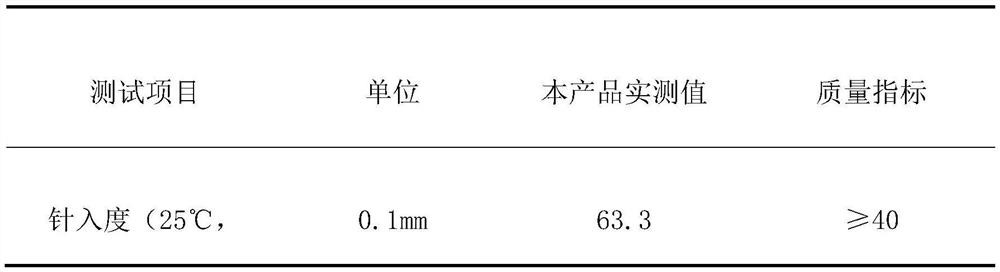

Embodiment 3

[0051] The modified asphalt formula of this embodiment is as follows: matrix asphalt 5kg, composite reinforcing fiber is formed by compounding 50g basalt fiber and 50g polyester fiber, additives include 80g compatibilizer, 80gSBS, 20gEVA, 0.6g sulfur powder, 150g rubber powder, 100g terpene resin, 40g thermoplastic rubber and 8g anti-peeling agent; the rubber powder includes 49.0wt% rubber hydrocarbon, 11.5wt% acetone extract, 32.0wt% carbon black and 7.5wt% ash.

[0052] The preparation method is the same as in Example 1. The modified resin prepared in this example was subjected to a performance test, and the test results are shown in Table 3.

[0053] table 3

[0054]

[0055] The thermal stability test was carried out on Examples 1-3, and the thermal stability test was evaluated by the dynamic stability (rutting test) test. Take the modified asphalt without adding composite reinforcing fiber, and the other components and preparation method are the same as those in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com