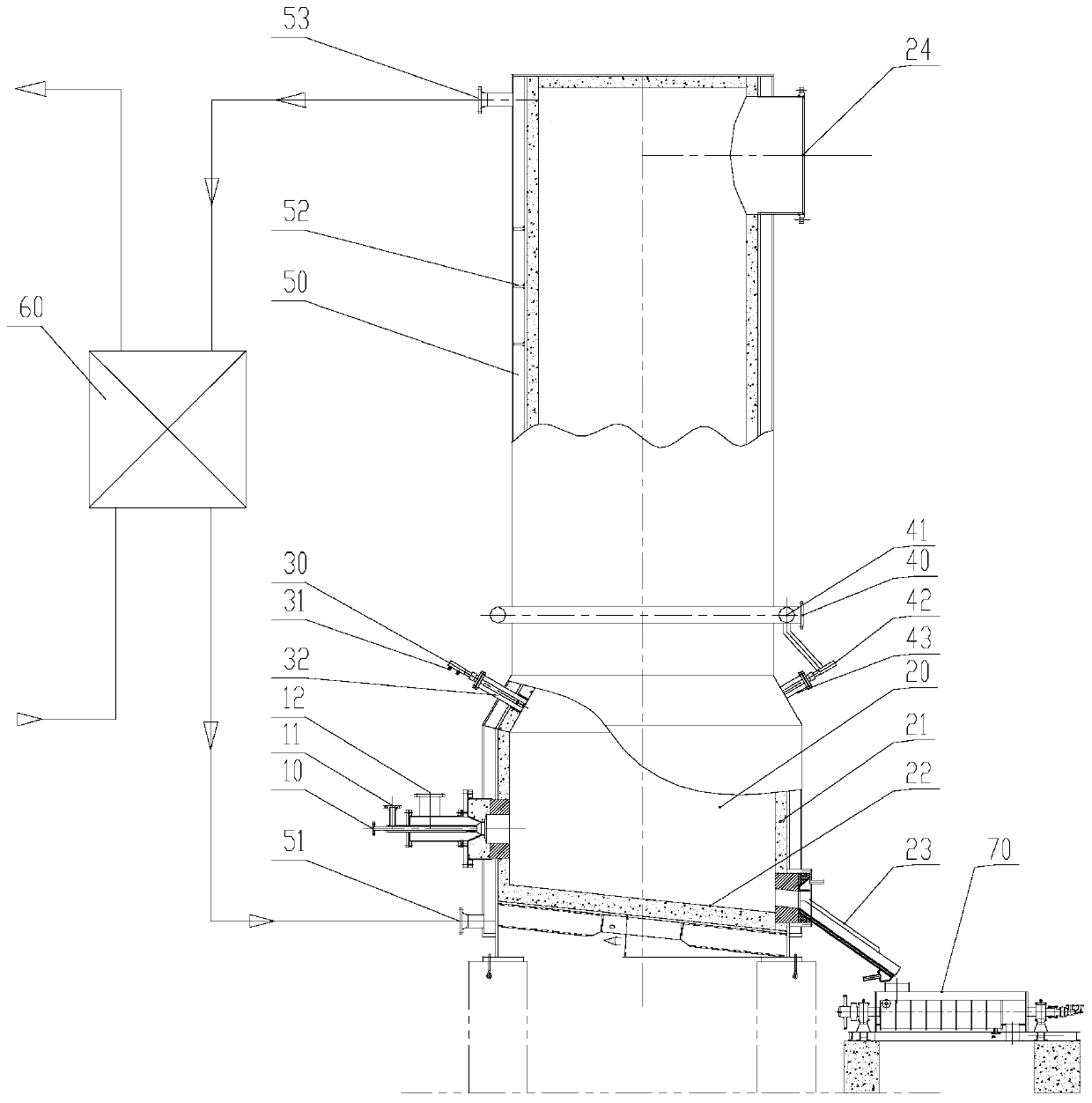

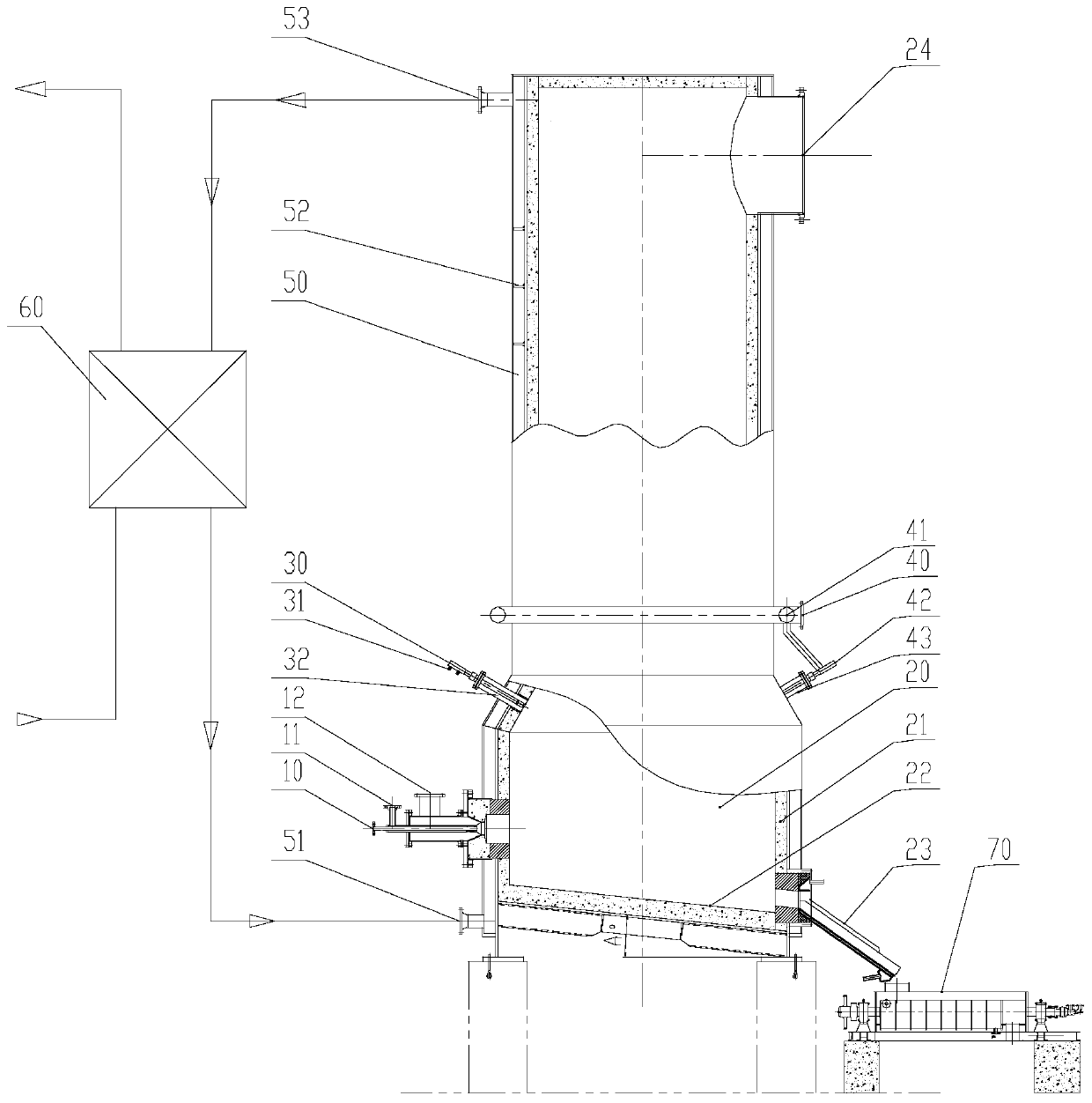

Water cooling jacket incineration device and method for processing salt-containing waste liquid and waste gas

A water-cooled jacket, salt-containing waste liquid technology, applied in combustion methods, incinerators, combustion types, etc., can solve the problems of increased operating costs, system acid dew point corrosion, high maintenance costs, etc., and achieve extended service life and low cost. Stable operation to ensure long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] The device of the invention is an environment-friendly device that adopts a high-temperature incineration method to realize harmless treatment of salty waste liquid and waste gas produced in petrochemical, coal chemical, papermaking, pesticide and other industrial industries. For such salt-containing waste liquid and waste gas, the common problems of conventional treatment devices and methods are: short life of the lining and high energy consumption in operation; the present invention uses the design of the water-cooled jacket device to make the temperature of the furnace lining to the fire surface lower than that of molten salt ash Melting point, molten salt solidifies to form a protective layer, avoids high-temperature molten salt erosion of the furnace lining, realizes "resisting slag with slag", and prolongs the service life...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com