A construction method for subway single-storey underground digging stations

A construction method and station technology, which can be used in earth-moving drilling, underground chambers, shaft equipment, etc., can solve the problems of difficult construction of steel pipe columns, difficult construction, difficult deformation control, etc., so as to improve the level of mechanized construction and reduce manual digging. Risks and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

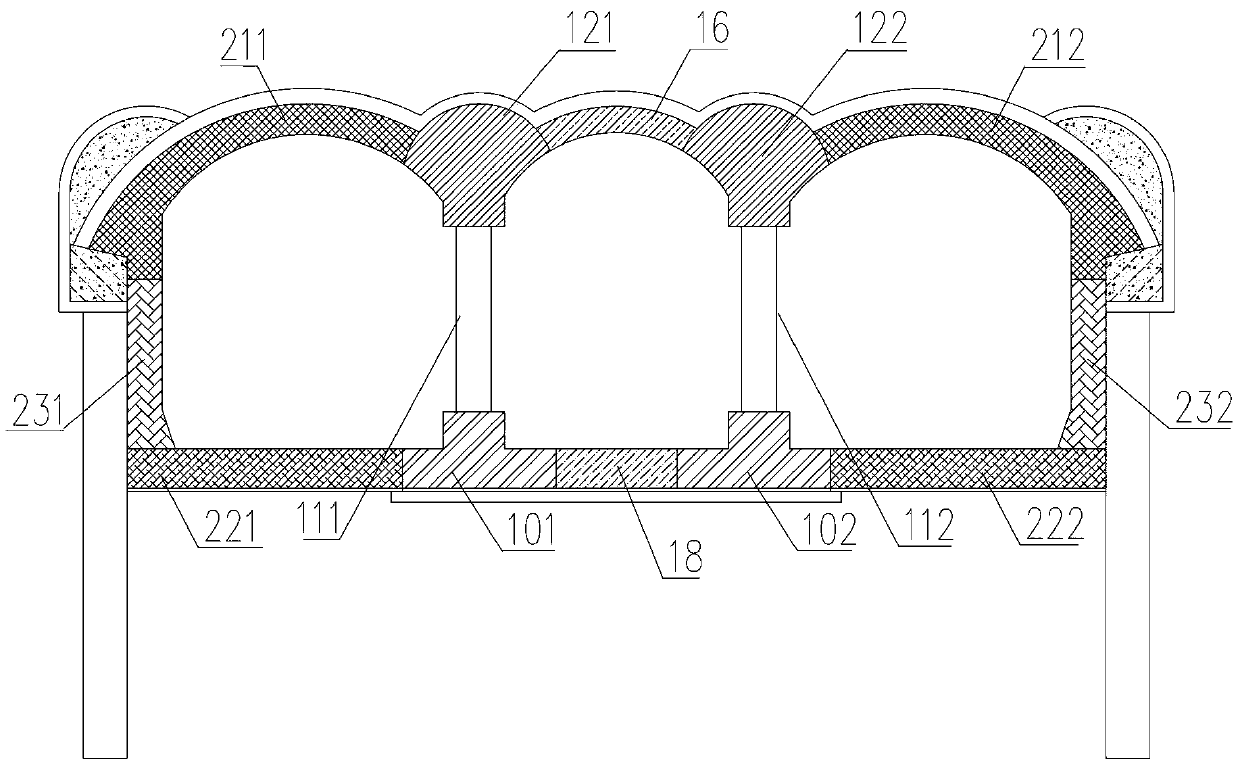

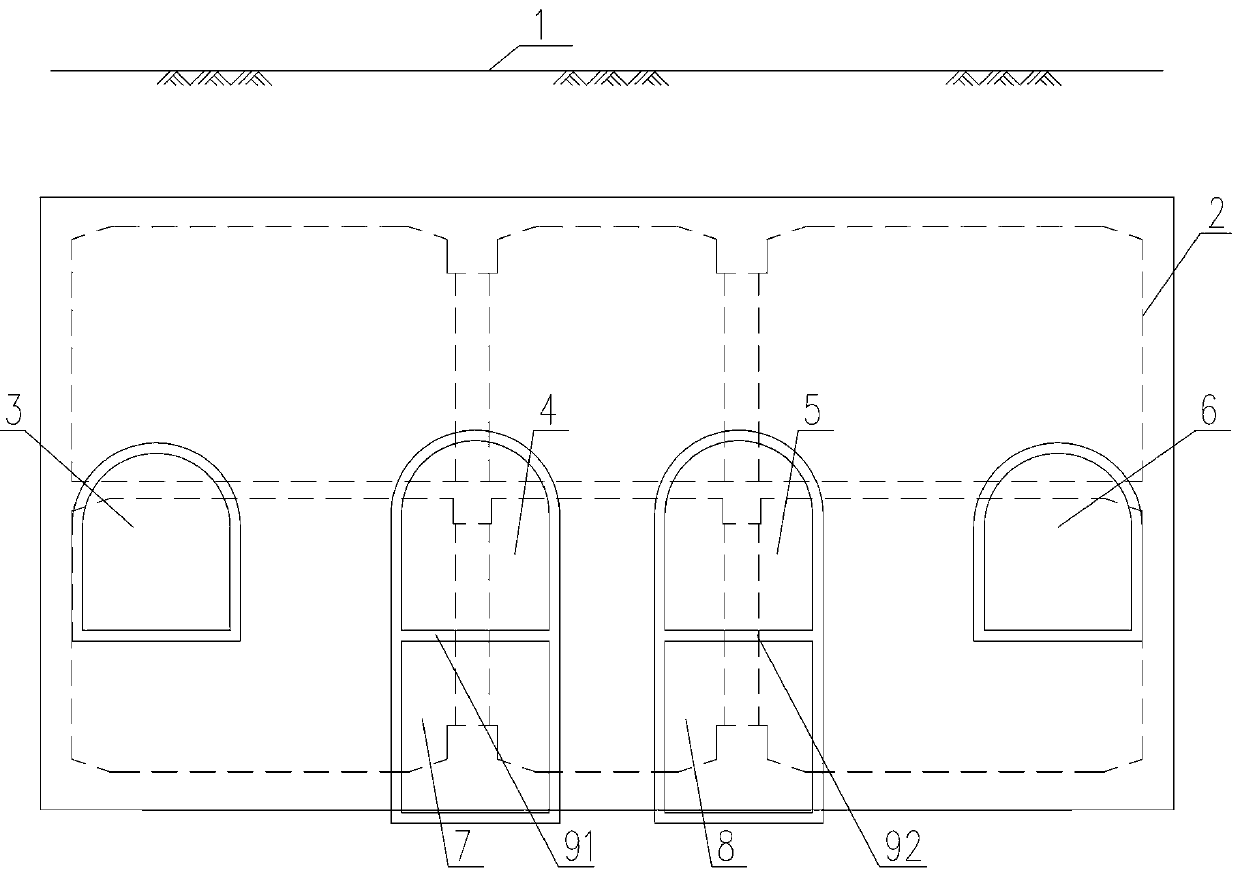

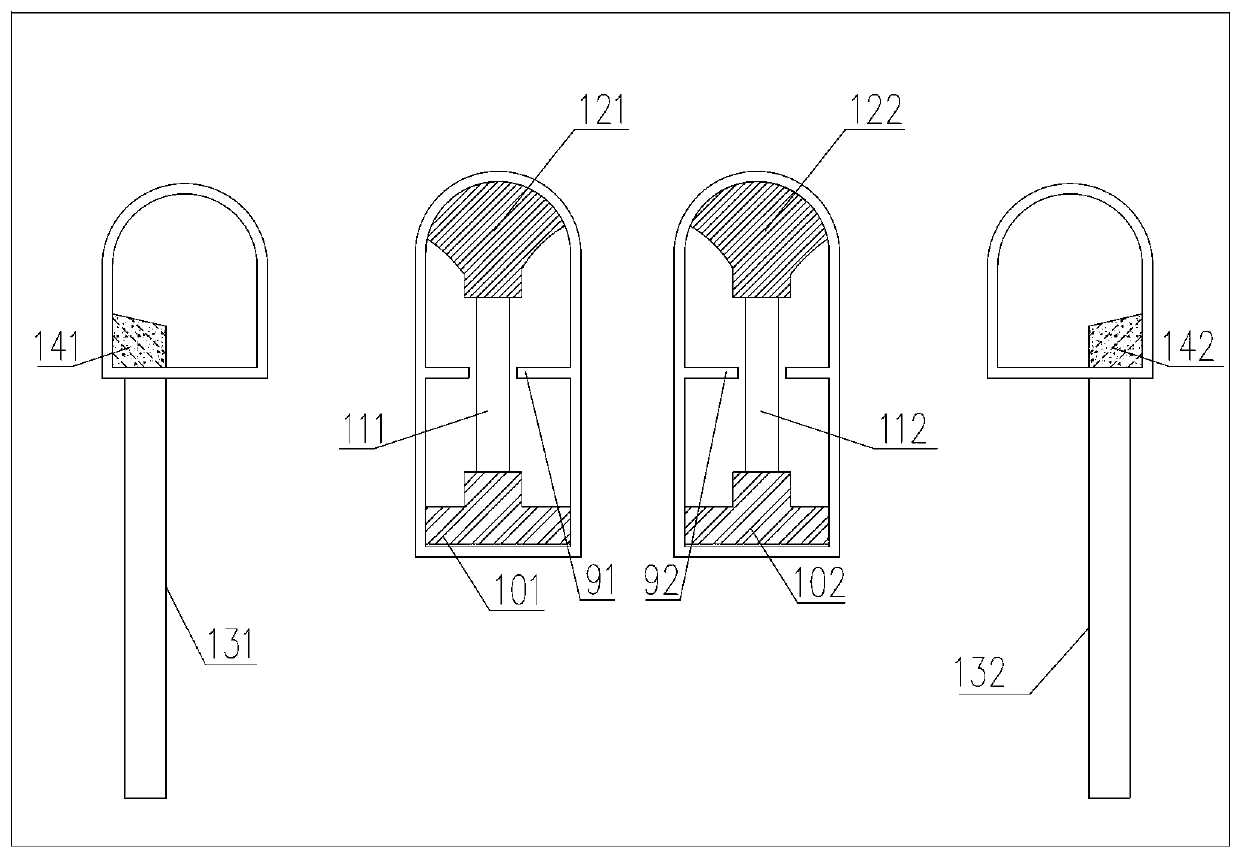

[0035] as attached Figure 1-9 Shown, the construction method of a kind of subway single-layer underground digging station of the present invention adopts following steps:

[0036] Step 1, two-story station structure at both ends of the cut-and-cut road 1, construct the lead tunnel of the cut-and-cut station from the end wall 2 of the cut-and-cut station structure at the junction with the cut and cut station; The side guide holes on both sides of the middle guide hole; the middle guide hole includes the left middle guide hole and the right middle guide hole arranged side by side; the left side middle guide hole includes the left upper layer middle guide hole 4 and the The middle guide hole 7 in the left lower layer at the bottom of the middle guide hole 4 in the upper layer of the side; the left side horizontal support 91 is set between the middle guide hole 4 in the left upper layer and the middle guide hole 7 in the left lower layer; The guide hole 5 in the upper layer on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com