Water-based electronic industrial scaling powder cleaning agent and preparation method thereof

A technology of electronics industry and cleaning agent, applied in the field of cleaning agent, can solve the problems of cleaning device pollution and residue, reduce the toxicity of cleaning agent, human body toxicity, etc., and achieve the effect of safe use, good cleaning effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

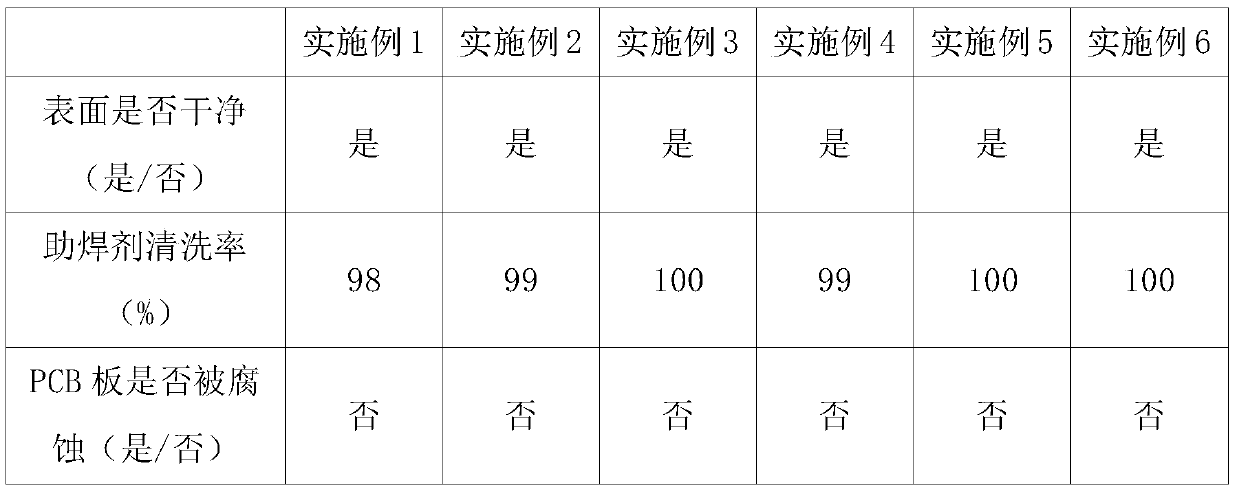

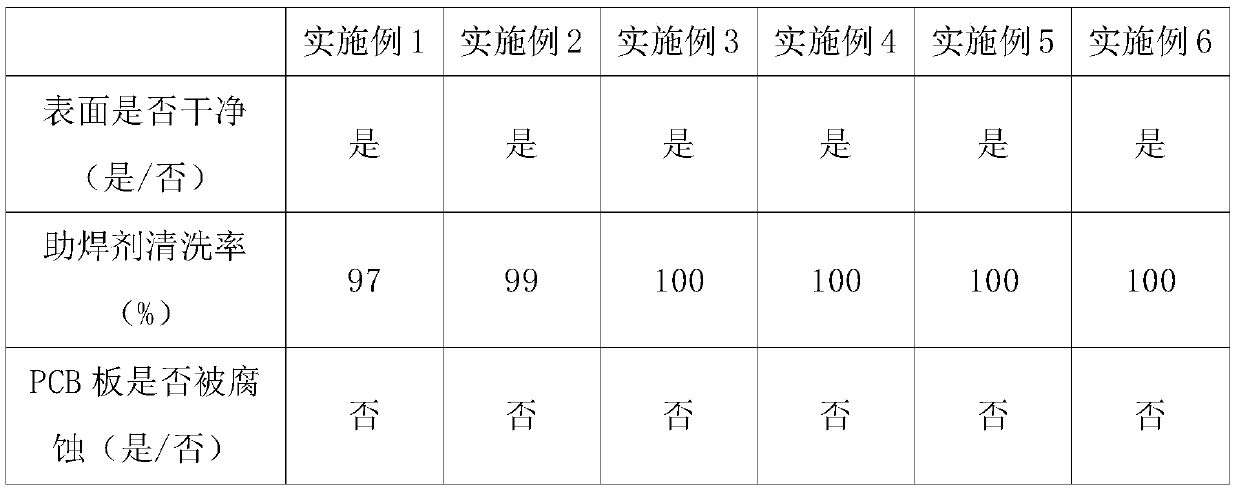

Examples

Embodiment 1

[0023] A water-based electronic industry soldering flux cleaning agent, each component in its formula is as follows by weight:

[0024] 55 parts of dipropylene glycol butyl ether, 20 parts of terpineol, 1 part of benzotriazole, 1 part of EH-6, 0.5 parts of OP-10, 1.5 parts of JFC-E, 1 part of sodium hydroxide, 20 parts of deionized water share.

[0025] The preparation method is: at the speed of 500r / m, add dipropylene glycol butyl ether, terpineol and benzotriazole to the reaction kettle in sequence, stir for 5 minutes, and add EH-6, OP-10 and JFC- E, Dissolve sodium hydroxide in deionized water in advance, and finally add the aqueous alkali solution into the reaction kettle, stir for 30 minutes, disperse evenly, cool to room temperature, and let stand to obtain a water-based electronic industry flux cleaning agent.

[0026] Usage method 1: Dilute the concentrated solution to 4 times of the original (mass ratio) and heat to 50°C, then ultrasonically clean the PCB board to be...

Embodiment 2

[0029] A water-based electronic industry soldering flux cleaning agent, each component in its formula is as follows by weight:

[0030] 60 parts of dipropylene glycol methyl ether, 20 parts of terpineol, 1 part of benzotriazole, 1 part of EH-6, 0.5 parts of OP-10, 1.5 parts of JFC-E, 1 part of sodium hydroxide, 15 parts of deionized water share.

[0031] The preparation method is as follows: at the speed of 800r / m, add dipropylene glycol methyl ether, terpineol and benzotriazole to the reaction kettle in sequence, stir for 5 minutes, and add EH-6, OP-10 and JFC- E, Dissolve sodium hydroxide in deionized water in advance, and finally add the aqueous alkali solution into the reaction kettle, stir for 30 minutes, disperse evenly, cool to room temperature, and let stand to obtain a water-based electronic industry flux cleaning agent.

[0032] Usage method 1: Dilute the concentrated solution to 5 times of the original (mass ratio) and heat to 50°C, then ultrasonically clean the PC...

Embodiment 3

[0035] A water-based electronic industry soldering flux cleaning agent, each component in its formula is as follows by weight:

[0036] 70 parts of dipropylene glycol propyl ether, 20 parts of terpineol, 1 part of benzotriazole, 1 part of EH-6, 0.5 parts of OP-10, 1.5 parts of JFC-E, 1 part of sodium hydroxide, 10 parts of deionized water share.

[0037] The preparation method is: at the speed of 1000r / m, add dipropylene glycol propyl ether, terpineol and benzotriazole to the reaction kettle in sequence, stir for 5 minutes, and add EH-6, OP-10 and JFC- E, Dissolve sodium hydroxide in deionized water in advance, and finally add the aqueous alkali solution into the reaction kettle, stir for 30 minutes, disperse evenly, cool to room temperature, and let stand to obtain a water-based electronic industry flux cleaning agent.

[0038] Usage method 1: Dilute the concentrated solution to 5 times of the original (mass ratio) and heat to 50°C, then ultrasonically clean the PCB board to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com