High-injection salt-resistant polymer for oil recovery, ternary composite system and preparation method thereof

A polymer and high-injection technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increasing dosage and reducing, and achieve the effects of enhancing ductility, high injection performance, and improving curling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

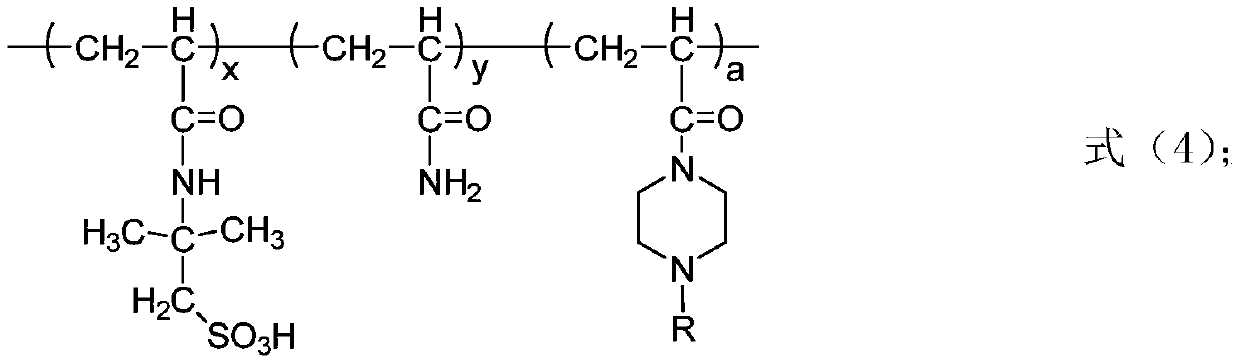

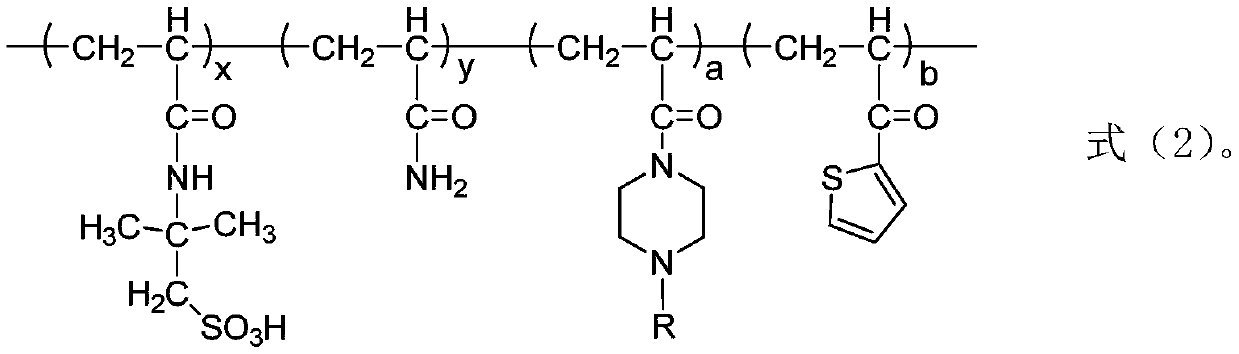

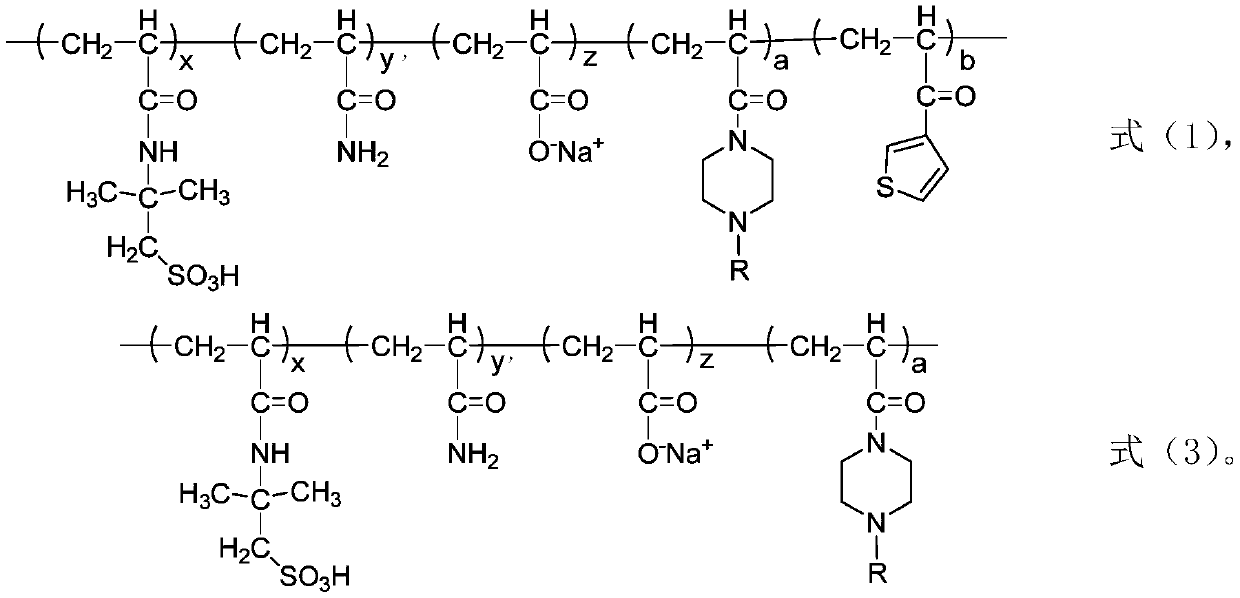

[0054] The present invention also provides the preparation method of above-mentioned polymer, specifically comprises the following steps:

[0055] The first step, by mass parts, 100 parts of raw materials include:

[0056] 2-acrylamido-2-methylpropanesulfonic acid AMPS (x monomer) 3.5-5 parts,

[0057] Acrylamide AM (y monomer) 18-20 parts,

[0058] N-acryloyl-N'-R base-piperazine (a monomer) 0.05-0.1 part,

[0059] 0.01-0.05 parts of 2-acryloylthiophene (monomer b),

[0060] OP-10 surfactant (OP-10 is octylphenol ethoxylate-10, chemical formula C 32 h 58 o 10 , CAS # : 9002-93-1, HLB value: 14.5, non-ionic surfactant, commonly used emulsifier) 0.1-0.5 parts,

[0061] Polymerization Catalyst 3-Aminopropionitrile H 2 NCH 2 CH 2 CN0.02-0.04 parts,

[0062] Ammonium persulfate ((NH 4 ) 2 S 2 o 8 )0.0002-0.0005 copies,

[0063] Sodium bisulfite (Na 2 SO 3 )0.0006-0.001 part,

[0064] Azobisisoheptanonitrile (C 12 h 24 N 4 )0.01-0.02 parts,

[0065] the res...

Embodiment 1

[0072] Add 737.8g of distilled water to a 1L jar, then add 10g of sodium hydroxide, mix well, then slowly add 50g of functional monomer AMPS, after the AMPS is completely dissolved in a constant temperature water bath below 15°C, add N-acryloyl-N'-R group -Piperazine 0.5g, then add 2g of OP-10 surfactant, stir evenly, add 200g of acrylamide monomer AM, adjust the pH value to 12, then cool down to -2°C; % of high-purity nitrogen for 10 minutes, add polymerization catalyst 3-aminopropionitrile and disodium EDTA 0.01g, continue to pass nitrogen to remove oxygen for 20 minutes, then add 0.2 g of azobisisoheptanonitrile, and then pass nitrogen to remove oxygen for 20 minutes. Add 0.008 g of ammonium persulfate, and then add 0.02 g of sodium bisulfite after 2 minutes, then continue to pass nitrogen gas until the solution becomes viscous and then seal it.

[0073] After the temperature of the solution rises to the highest value, cool down naturally for 2 hours, and the reaction system ...

Embodiment 2

[0075] First add 774g of distilled water to a 1L beaker, then add 7g of sodium hydroxide, mix well, then slowly add 35g of functional monomer AMPS, after the AMPS is completely dissolved in a constant temperature water bath below 15°C, add N-acryloyl-N'-Ryl-piperazine 1.0g, then add 2g of OP-10 surfactant, stir evenly, add 180g of acrylamide monomer AM, adjust the pH value to 12.5, then cool down to -5°C; Deoxygenate with high-purity nitrogen for 10 minutes, add polymerization catalyst 3-aminopropionitrile and 0.05 g of disodium EDTA, continue to pass nitrogen gas for deoxygenation for 20 minutes, then add 0.15 g of azobisisoheptanonitrile, and then pass nitrogen gas for deoxygenation for 20 minutes, then add persulfuric acid Ammonium 0.008g, 0.02g sodium bisulfite was added after 2 minutes, and then nitrogen gas was continued until the solution became viscous and then sealed.

[0076] After the temperature of the solution rises to the highest value, cool down naturally for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com