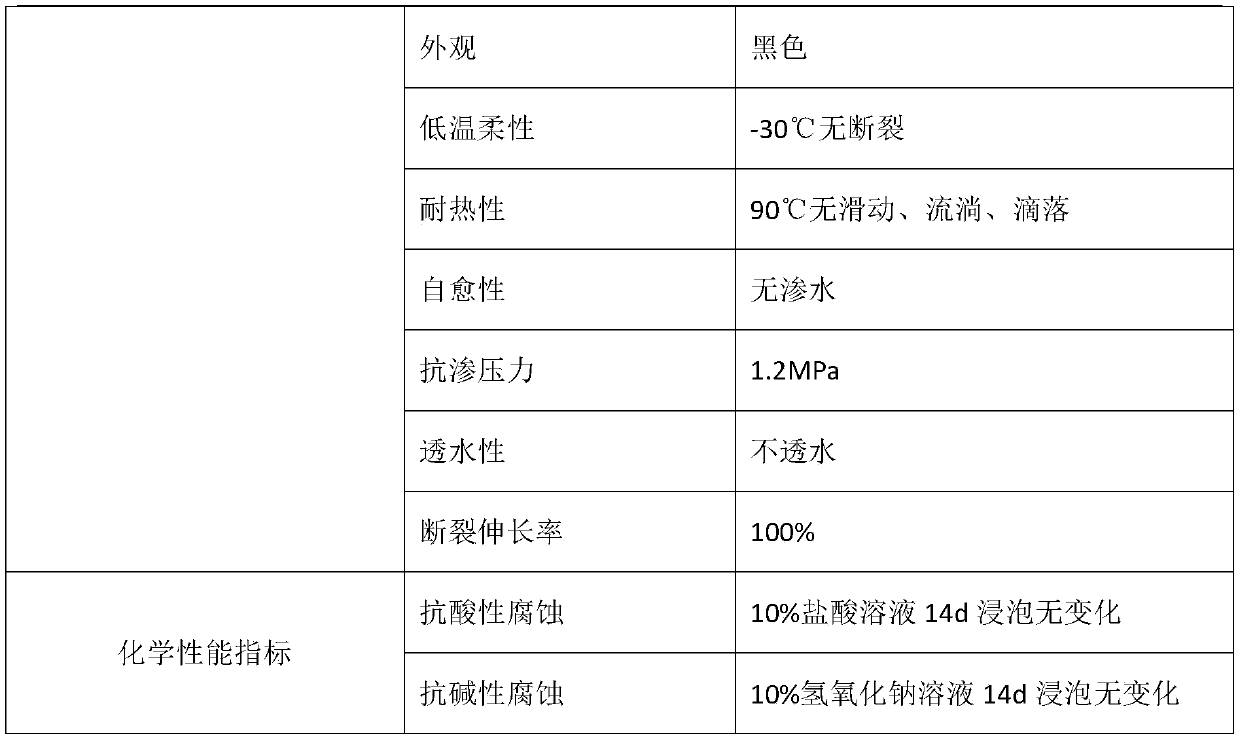

High-performance asphalt sealing waterproof anti-corrosion adhesive and preparation method thereof

A high-performance, adhesive technology, applied in asphalt material adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high temperature resistance, low temperature flexibility and tear strength Realize problems such as simultaneous lifting, base material deformation, complex production process, etc., and achieve the effects of excellent self-repair function, good creep and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-performance asphalt sealing waterproof anti-corrosion adhesive, made of the following components by weight: 30 parts of petroleum asphalt, 20 parts of modifier, 5 parts of softening agent, 3 parts of crosslinking agent, 1 part of catalyst, 3 parts of solubilizer, 20 parts of micro-expansion filler.

[0028] In order to achieve a better technical effect, the above-mentioned 30 parts of petroleum asphalt is a composition of 5 parts of 70# petroleum asphalt, 10 parts of 90# petroleum asphalt and 15 parts of 100# petroleum asphalt.

[0029] In order to achieve a better technical effect, the above-mentioned 20 parts modifier is a composition of 5 parts of epoxy resin, 5 parts of C5 petroleum resin, 5 parts of rosin resin and 5 parts of butyl rubber.

[0030] In order to achieve a better technical effect, the above-mentioned 5 parts softening agent is a composition of 3 parts of 120# solvent oil and 2 parts of naphthenic oil.

[0031] In order to achieve a better tech...

Embodiment 2

[0040] High-performance asphalt sealing waterproof and anti-corrosion adhesive, made of the following components by weight: 60 parts of petroleum asphalt, 30 parts of modifier, 10 parts of softener, 5 parts of crosslinking agent, 2 parts of catalyst, solubilizer 6 parts, micro expansion filler 40 parts.

[0041] In order to achieve better technical effects, the above-mentioned 60 parts of petroleum asphalt is a composition of 10 parts, 70# petroleum asphalt, 30 parts of 90# petroleum asphalt and 20 parts of 100# petroleum asphalt.

[0042] In order to achieve a better technical effect, the above 30 parts modifier is a combination of 5 parts polydiallyl phthalate, 10 parts epoxy resin, 5 parts C5 petroleum resin, 5 parts rosin resin and 5 parts butyl rubber thing.

[0043] In order to achieve a better technical effect, the above-mentioned 10 parts of softening agent is a composition of 3 parts of 120# solvent naphtha, 3 parts of ethyl acetate, 2 parts of butyl acetate and 2 pa...

Embodiment 3

[0053] A high-performance asphalt sealing waterproof anti-corrosion adhesive, made of the following components by weight: 50 parts of petroleum asphalt, 25 parts of modifier, 8 parts of softening agent, 4 parts of crosslinking agent, 1 part of catalyst, 5 parts of solubilizer, 30 parts of micro-expansion filler.

[0054] In order to achieve better technical effect, above-mentioned 50 parts of petroleum pitches are the composition of 10 parts, 70# petroleum pitches, 20 parts of 90# petroleum pitches and 20 parts of 100# petroleum pitches.

[0055] In order to achieve a better technical effect, the above 25 parts modifier is a combination of 5 parts polydiallyl phthalate, 5 parts epoxy resin, 5 parts C5 petroleum resin, 5 parts rosin resin and 5 parts butyl rubber thing.

[0056] In order to achieve a better technical effect, the above-mentioned 8 parts of softening agents are a composition of 2 parts of 120# solvent naphtha, 2 parts of ethyl acetate, 2 parts of butyl acetate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com