Boiler flue gas denitration system adopting SNCR/SCR mixing process

A boiler flue gas and mixing process technology, applied in lighting and heating equipment, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of lack of SNCR function and anti-corrosion function, low service life of equipment, and low denitrification efficiency. Achieve the effect of improving service life, improving effect and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

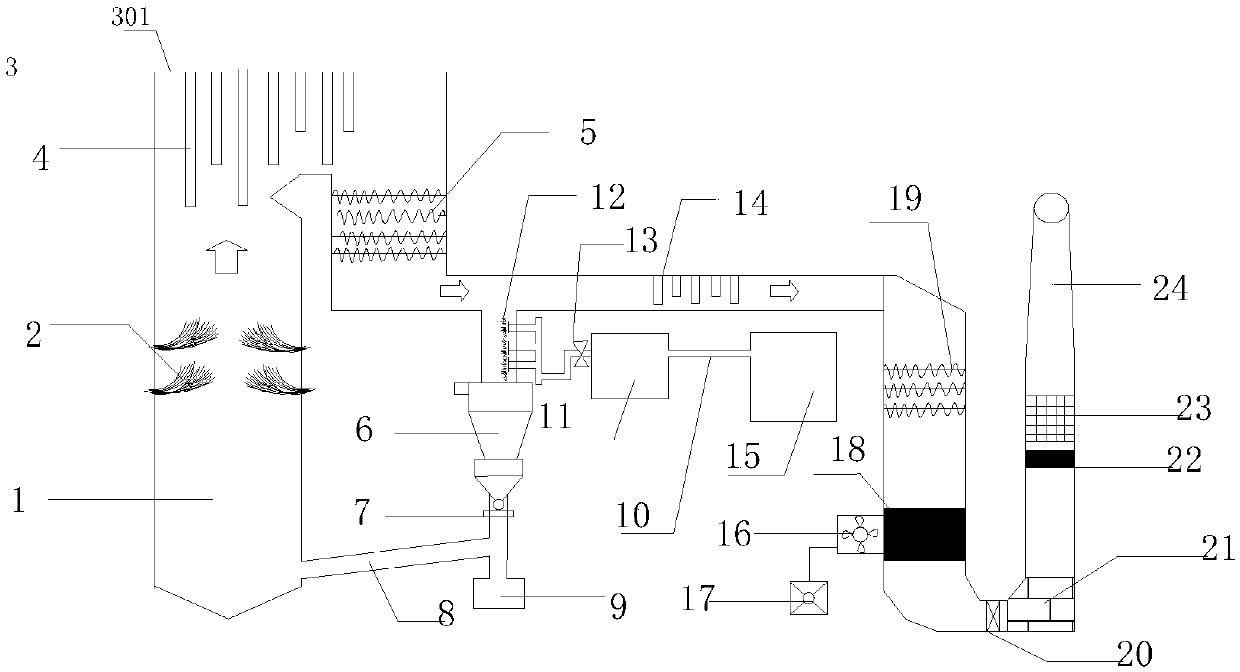

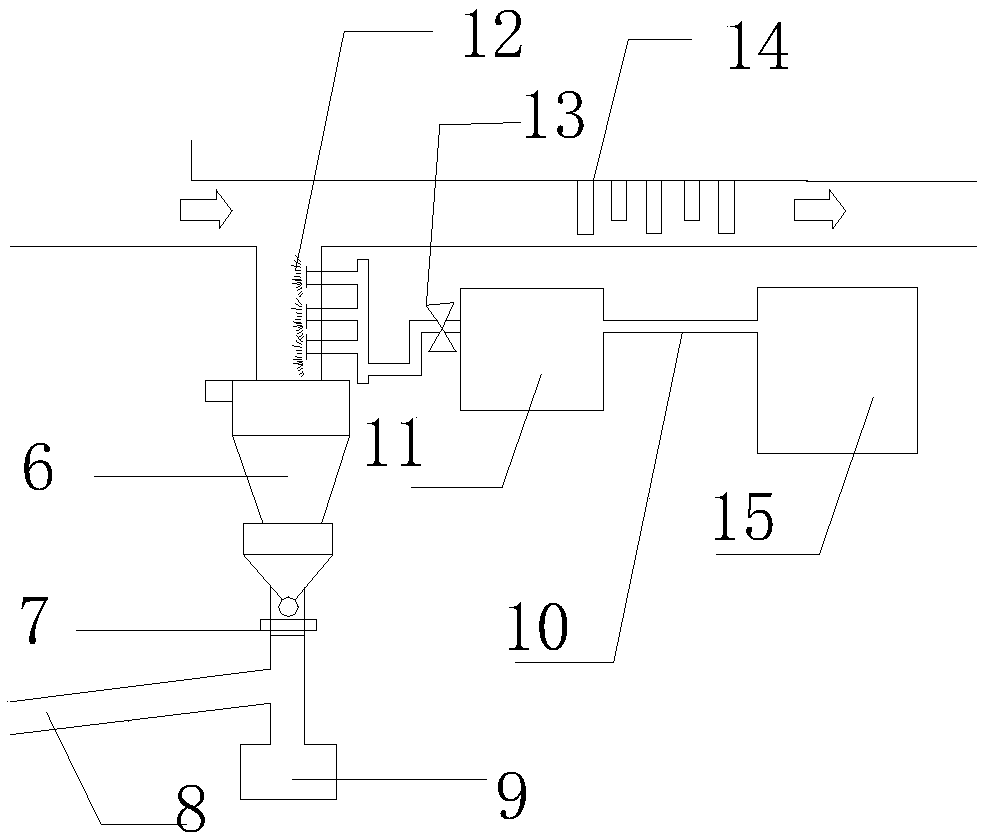

[0016] A boiler flue gas denitrification system adopting SNCR / SCR mixed process, its structure includes air inlet 1, gas buffer brush 2, stainless steel shell 3, anti-corrosion copper plating film 301, primary superheater 4, and primary boiler economizer 5. High-temperature cyclone dust removal device 6, sealing ring 7, feeding device 8, water storage tank 9, anti-corrosion hose 10, ammonia substance solution controller 11, atomization device 12, regulating valve 13, secondary superheater 14, amino substance Solution storage tank 15, soot blower 16, small motor 17, SCR denitrification catalytic layer 18, secondary boiler economizer 19, static mixer 20, desulfurization chamber 21, demister 22, rectifying grille 23, chimney outlet 24 The gas buffer brush 2 is fixed inside the air inlet 1, the primary superheater 4 and secondary superheater 14 are connected to the stainless steel shell 3, the primary boiler economizer 5, and the secondary boiler economizer The device 19 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com