Decoration line with groove embedding structure and production technology of decoration line

A technology of mosaic structure and decorative lines, applied in the direction of building structure, construction, etc., can solve the problems of large product size error, long construction period, and falling off, etc., and achieve small product size error, convenient and fast installation, and uniform focus point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

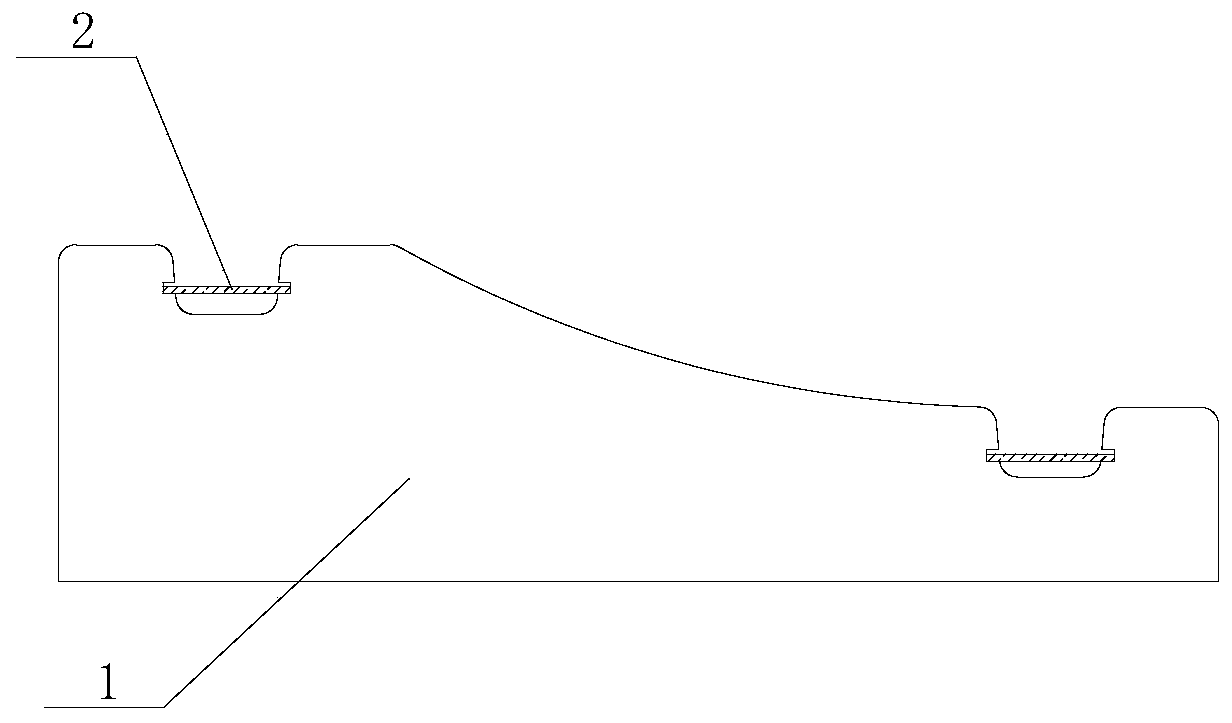

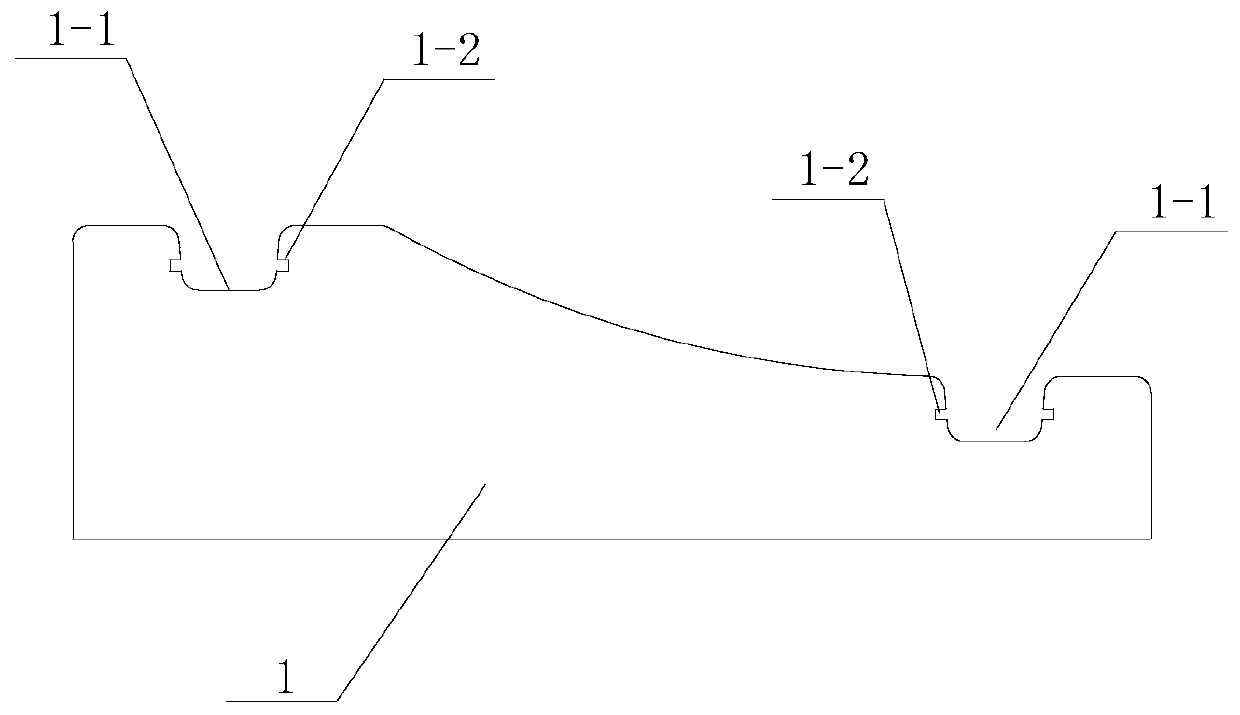

[0022] Example: see Figure 1-2 As shown, it includes a line body 1 and a decorative strip 2; both sides of the line body 1 are provided with a U-shaped groove 1-1; both sides of the inner wall of the U-shaped groove 1-1 are provided with symmetrical slots 1-2; the decorative strip 2 inserted in the slot 1-2;

[0023] The production process of the above-mentioned moldings with a groove mosaic structure includes the following process:

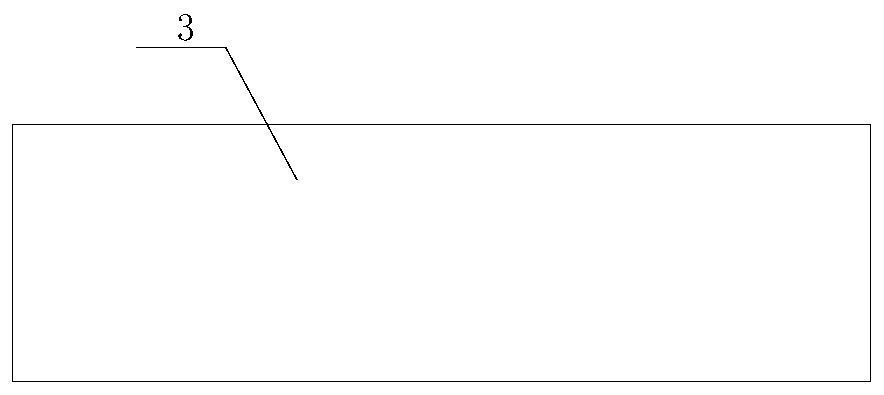

[0024] 1. First cut the raw materials into strips or plates according to the size required by the order to make a semi-finished product-3; for the structure of the semi-finished product-3, please refer to image 3 As shown; the raw material can be one of aluminum, copper, glass, stone, plastic, stainless steel, wood, ceramics, artificial stone (granite), and stone plastic;

[0025] 2. Place the semi-finished product 1 on the molding machine, and shape the contour through the molding machine to make the semi-finished product 2; the structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com