A kind of in-situ modified rubber composition for tire, tire and preparation method thereof

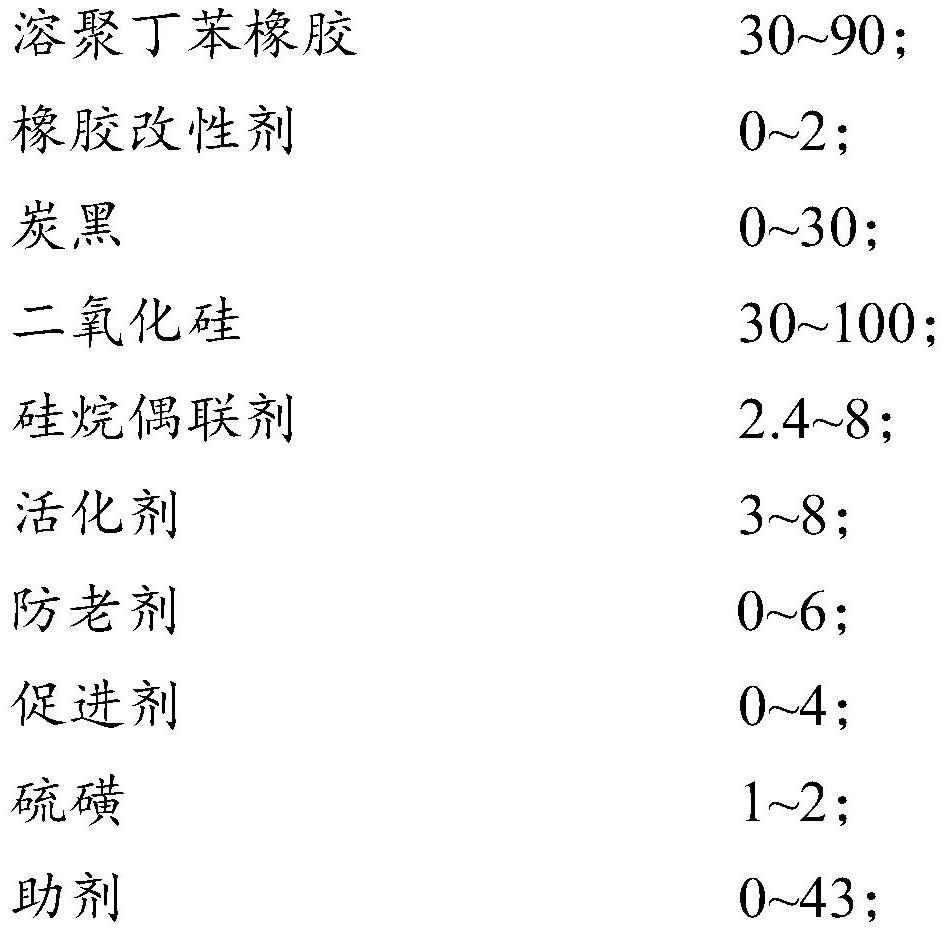

A rubber composition, in-situ modification technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as high rolling resistance, difficulty in dispersion, and non-compliance with the design concept of green tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

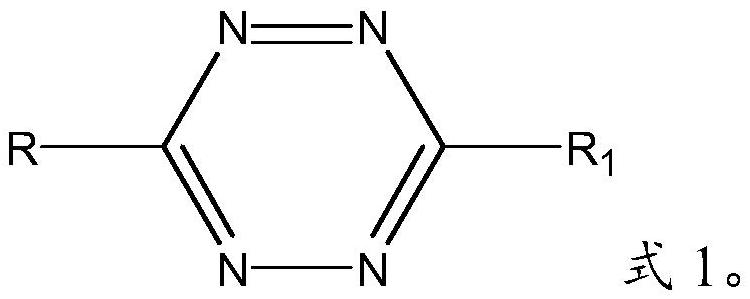

Method used

Image

Examples

Embodiment 1

[0054] The present embodiment provides the first tire, and the specific preparation method is as follows:

[0055] 1. Preparation method of modified solution-polymerized styrene-butadiene rubber polymer:

[0056] In terms of weight: 265.8 kg of oil-filled solution-polymerized styrene-butadiene rubber, 38.6 kg of carbon black, and 0.54 kg of rubber modifier. Put the above composition materials into BB430 type internal mixer for mixing in turn, the rotor speed is 10-60r / min, the glue discharge temperature is 135°C, and then the sheet is discharged through the open mill, and the obtained modified solution-polymerized styrene-butadiene rubber polymer Record it as MB1.

[0057] 2. The preparation method of the tire:

[0058] By weight: MB1 is 113.6kg, NR is 28kg, carbon black is 17.6kg, silicon dioxide is 60Kg, silane coupling agent is 4.8Kg, oil is 15kg, zinc oxide is 3kg, stearic acid is 2kg, for The phenylenediamine antioxidant is 2kg, the quinoline antioxidant is 1kg, the pa...

Embodiment 2

[0060] The present embodiment provides the second tire, and the specific preparation method is as follows:

[0061] 1. Preparation method of modified solution-polymerized styrene-butadiene rubber polymer:

[0062] In terms of weight: 265.3 kg of oil-filled solution-polymerized styrene-butadiene rubber, 38.6 kg of carbon black, and 1.08 kg of rubber modifier. Put the above composition materials into BB430 type internal mixer for mixing in turn, the rotor speed is 10-60r / min, the glue discharge temperature is 135°C, and then the sheet is discharged through the open mill, and the obtained modified solution-polymerized styrene-butadiene rubber polymer Denote it as MB2.

[0063] 2. The preparation method of the tire:

[0064] By weight: MB2 is 114kg, NR is 28kg, carbon black is 17.6kg, silicon dioxide is 60Kg, silane coupling agent is 4.8Kg, oil is 15kg, zinc oxide is 3kg, stearic acid is 2kg, p-phenylene The diamine antioxidant is 2kg, the quinoline antioxidant is 1kg, the para...

Embodiment 3

[0066] The present embodiment provides the third kind of tire, and the specific preparation method is:

[0067] 1. Preparation method of modified solution-polymerized styrene-butadiene rubber polymer:

[0068] By weight: 263.9 kg of oil-filled solution-polymerized styrene-butadiene rubber, 38.39 kg of carbon black, and 2.69 kg of rubber modifier. Put the above composition materials into BB430 type internal mixer for mixing in turn, the rotor speed is 10-60r / min, the glue discharge temperature is 135°C, and then the sheet is discharged through the open mill, and the obtained modified solution-polymerized styrene-butadiene rubber polymer Recorded as MB3.

[0069] 2. The preparation method of the tire:

[0070] By weight: MB3 is 114.5kg, NR is 28kg, carbon black is 17.6kg, silicon dioxide is 60Kg, silane coupling agent is 4.8Kg, oil is 15kg, zinc oxide is 3kg, stearic acid is 2kg, for The phenylenediamine antioxidant is 2kg, the quinoline antioxidant is 1kg, the paraffin is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| ash containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com