A kind of polycyclic carbonate resin and its rapid preparation method and application under normal pressure

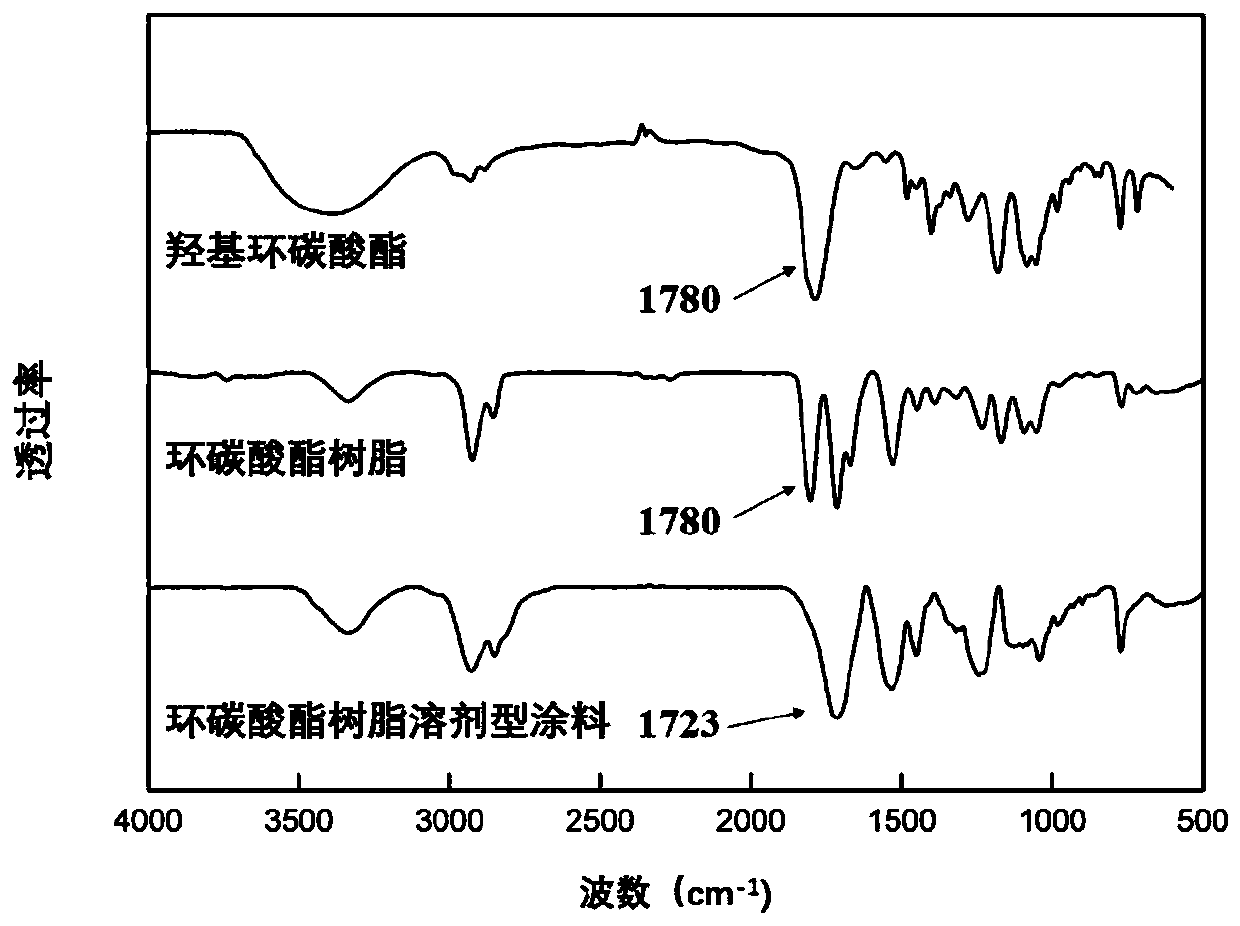

A technology of carbonate resin and hydroxycyclic carbonate, which is applied in the field of carbonate resin, can solve the problems of easily mixed with impurities, unsatisfactory purity, increase reaction rate, etc., and achieve shortened reaction time, superior mechanical properties, and reduced toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

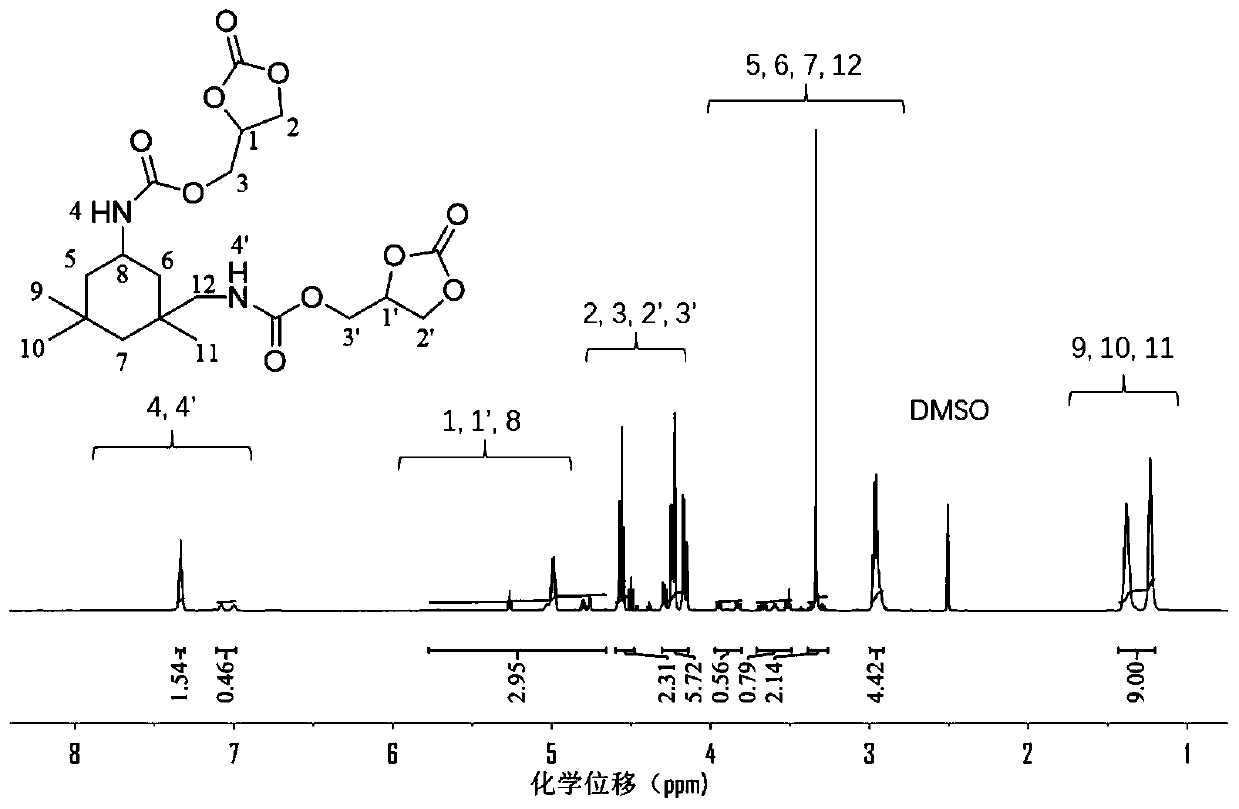

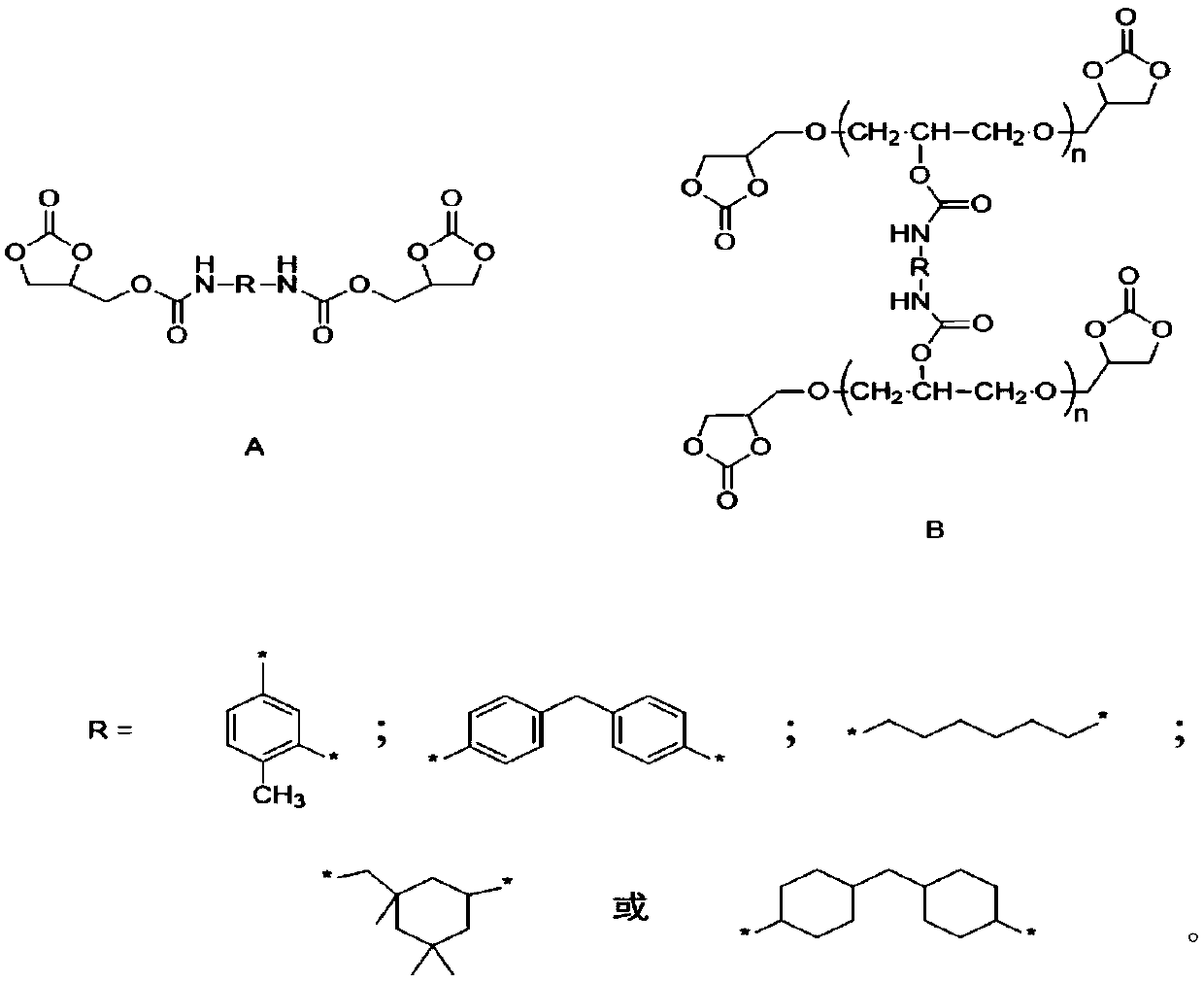

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of Hydroxycyclic Carbonate

[0039] The raw material formula of hydroxycyclic carbonate is as table 1:

[0040] Table 1

[0041]

[0042] Preparation method: Add metered glycerin, dimethyl carbonate and potassium carbonate into a three-neck flask equipped with a thermometer, condenser and stirring paddle, raise the temperature to 70°C, keep it warm for 1h, cool down to 40°C and distill under reduced pressure for 1h to remove the by-product methanol and residual dimethyl carbonate, combined with deionized water and potassium carbonate to form hydrated potassium carbonate, to precipitate and remove, after filtering, drop to room temperature and remove water with anhydrous calcium sulfate to obtain hydroxycyclic carbonate.

[0043] Hydroxycyclic carbonate properties: transparent light yellow low viscosity liquid, moisture content < 0.05%, catalyst content < 0.01%, solid content 98%, after drying at 90°C for 2 hours, the hydroxyl value is 478mgKOH / g.

...

Embodiment 2

[0062] 1) Preparation of hydroxycyclic carbonate:

[0063] The formula is shown in Table 5:

[0064] table 5

[0065]

[0066] Preparation method: Add metered glycerin, dimethyl carbonate and potassium hydroxide into a three-neck flask equipped with a thermometer, condenser and stirring paddle, raise the temperature to 60°C, keep it warm for 2.5h, cool down to 40°C, and distill under reduced pressure for 1.2h , remove the by-product methanol and residual dimethyl carbonate, use deionized water to precipitate the catalyst, filter it down to room temperature and dry it with anhydrous calcium sulfate for storage.

[0067] Properties of hydroxycyclic carbonate: transparent light yellow low viscosity liquid, moisture content < 0.05%, catalyst content < 0.05%, solid content 98%, hydroxyl value 474mgKOH / g after drying at 90°C for 2 hours.

[0068] 2). Preparation of cyclocarbonate resin:

[0069] The formula is shown in Table 6:

[0070] Table 6

[0071]

[0072] Preparati...

Embodiment 3

[0083] 1) Preparation of hydroxycyclic carbonate:

[0084] The formula is shown in Table 9:

[0085] Table 9

[0086]

[0087] Preparation method: Add metered glycerin, diethyl carbonate and sodium carbonate into a three-necked flask equipped with a thermometer, condenser and stirring paddle, raise the temperature to 75°C, keep it warm for 0.5h, cool down to 40°C, and distill under reduced pressure for 0.8h. The by-product ethanol and residual diethyl carbonate were removed, the catalyst was precipitated with deionized water, filtered and then cooled to room temperature and stored with anhydrous calcium sulfate.

[0088] Hydroxycyclic carbonate properties: transparent light yellow low viscosity liquid, moisture content < 0.04%, catalyst content < 0.03%, solid content 98%, hydroxyl value 475mgKOH / g after drying at 90°C for 2 hours.

[0089] 2) preparation of cyclocarbonate resin:

[0090] The formula is shown in Table 10:

[0091] Table 10

[0092]

[0093] Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com