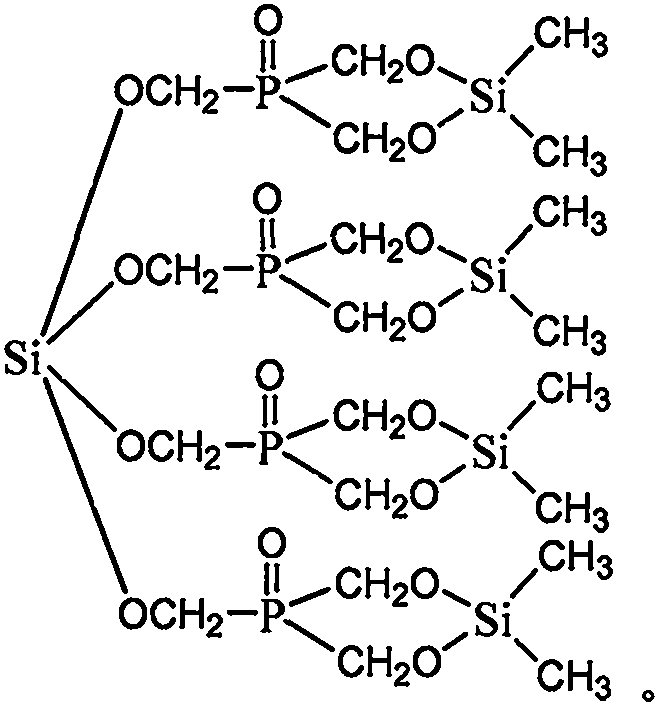

Flame retardant charring agent tetra(phosphono heterocyclic silicate methoxyl)silane compound and preparation method thereof

A technology of silane compound and trimethylol dimethyl silicate, which is applied in the field of tetrasilane compound, a flame-retardant char-forming agent, can solve the problems of flammable materials, hidden dangers of life and property safety, and achieve low cost and improved The effects of compatibility and good application development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

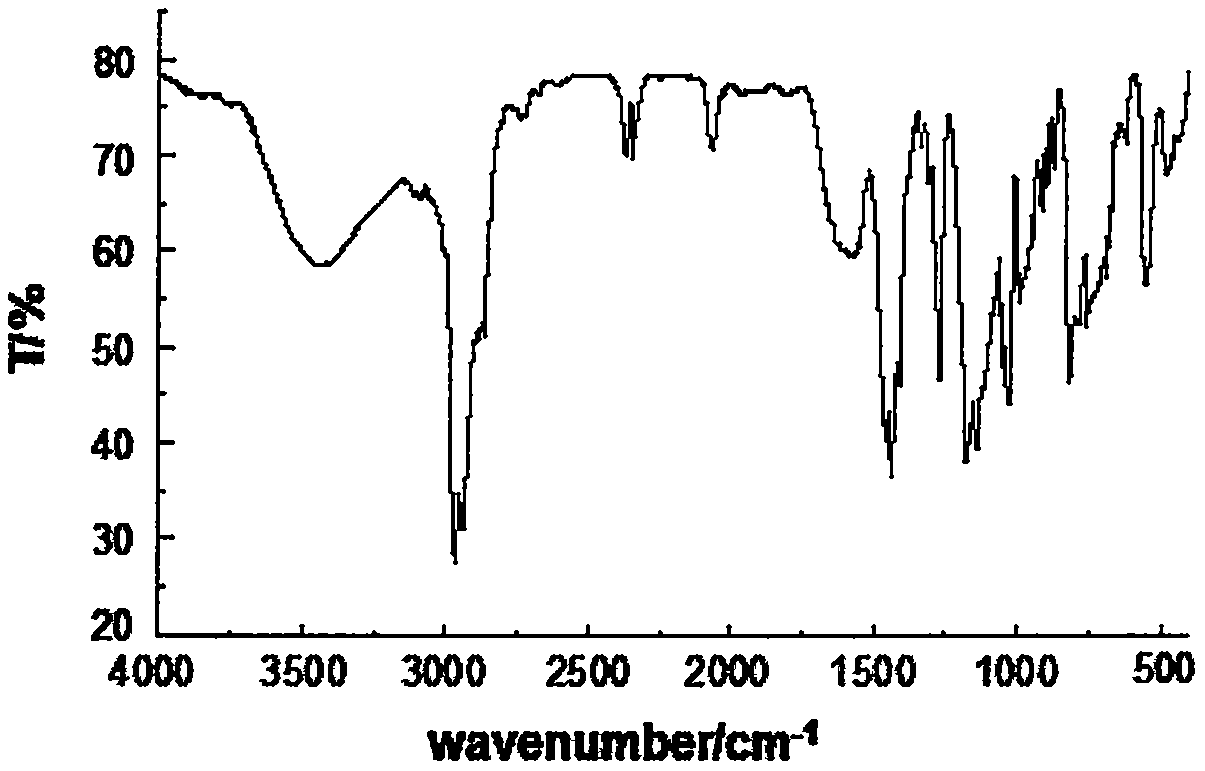

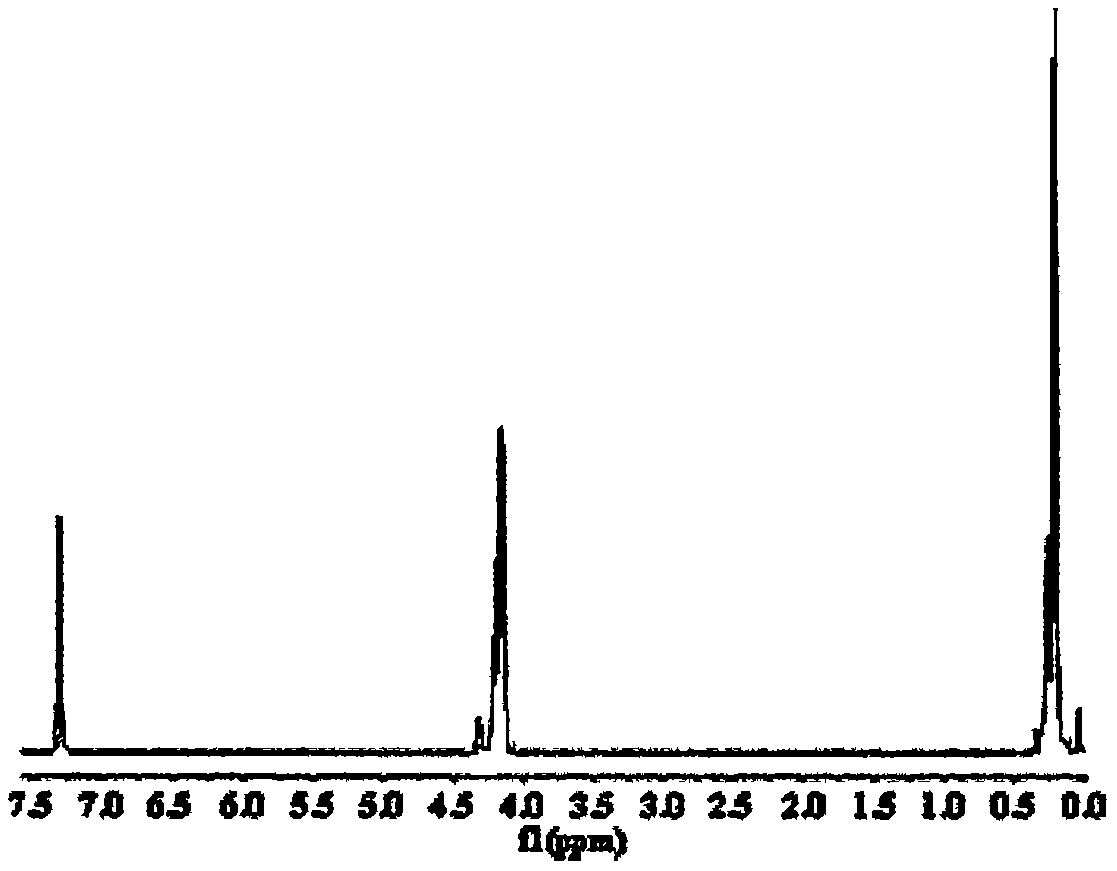

[0025] Example 1 In a 250ml four-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, and a hydrogen chloride absorption device at the top of the condenser, replace the air in the bottle with nitrogen, and add 39.2g (0.2mol) Trimethylolphosphine oxide cyclic ester of dimethyl silicate and 120ml of ethylene glycol dimethyl ether, after the trimethylol phosphine oxide cyclic ester of dimethyl silicate is dissolved and dispersed evenly, add 8.5g (0.05 mol) silicon tetrachloride, the dropping temperature does not exceed 50°C, after the dropping, raise the temperature to 85°C, keep the temperature for 12 hours, distill off the solvent under reduced pressure to obtain a turbid viscous liquid, cool it, and then pour the crude product into 120ml of ice water Stir rapidly for 30 minutes, let stand, and take off the lower layer of colorless viscous liquid to obtain the product flame-retardant char-forming agent tetrakis(phosphonoheterocyclic silicate ...

Embodiment 2

[0026] Example 2 In a 250ml four-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, and a hydrogen chloride absorbing device at the top of the condenser, replace the air in the bottle with nitrogen, and add 40.18g (0.205mol) Trimethylolphosphine oxide dimethylsilicate cyclic ester and 120ml acetonitrile, after trimethylolphosphine oxide cyclic dimethylsilicate is dissolved and dispersed evenly, add 8.5g (0.05mol) tetrachloride dropwise Silicon, the dropwise addition temperature does not exceed 50°C. After the dropwise addition, the temperature is raised to 80°C, and the temperature is kept for 12 hours. The solvent is distilled off under reduced pressure to obtain a turbid viscous liquid. After cooling, the crude product is poured into 120ml of ice water and stirred rapidly for 30 minutes, statically Place it, and take off the lower layer of colorless viscous liquid to obtain the product flame-retardant char-forming agent tetrakis(phosphon...

Embodiment 3

[0027] Example 3 In a 250ml four-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, and a hydrogen chloride absorbing device at the top of the condenser, replace the air in the bottle with nitrogen, and add 41.16g (0.21mol) Trimethylol phosphine oxide cyclic ester of dimethyl silicate and 120ml of dioxane, after the trimethylol phosphine oxide cyclic ester of dimethyl silicate is dissolved and dispersed evenly, add 8.5g (0.05mol) dropwise Silicon tetrachloride, the dropwise addition temperature does not exceed 50°C, after dropping, raise the temperature to 100°C, keep the temperature for 10 hours, distill off the solvent under reduced pressure to obtain a turbid viscous liquid, cool it, then pour the crude product into 120ml ice water and stir quickly After standing still for 30 minutes, the lower layer of colorless viscous liquid was taken to obtain the flame retardant char-forming agent tetrakis(phosphonoheterocyclic silicate methoxy)sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com