Application of magnesium hydride hydrogen production assistants, magnesium hydride hydrogen production mixed reagent and method for preparing hydrogen from magnesium hydride

A hydrogen additive, magnesium hydride technology, applied in the direction of hydrogen production, etc., can solve the problems of reducing the application efficiency of magnesium hydride hydrogen production fuel cells, poor reaction kinetics and thermodynamic performance, damage to the continuity of hydrolysis reaction, etc., and achieve start-up time Short, inexpensive, and easily mass-producible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1). In a glove box protected by nitrogen, mix magnesium hydride:X powder=1:0.15 according to the mass ratio, and then mechanically stir and mix uniformly to prepare reaction powder A.

[0056] 2) Put the reaction powder A in the reaction vessel, and wait for the liquid water to pass into the liquid water in the reaction powder A to start the hydrogen production reaction.

[0057] 3) The composition of X powder is AlCl 3 .

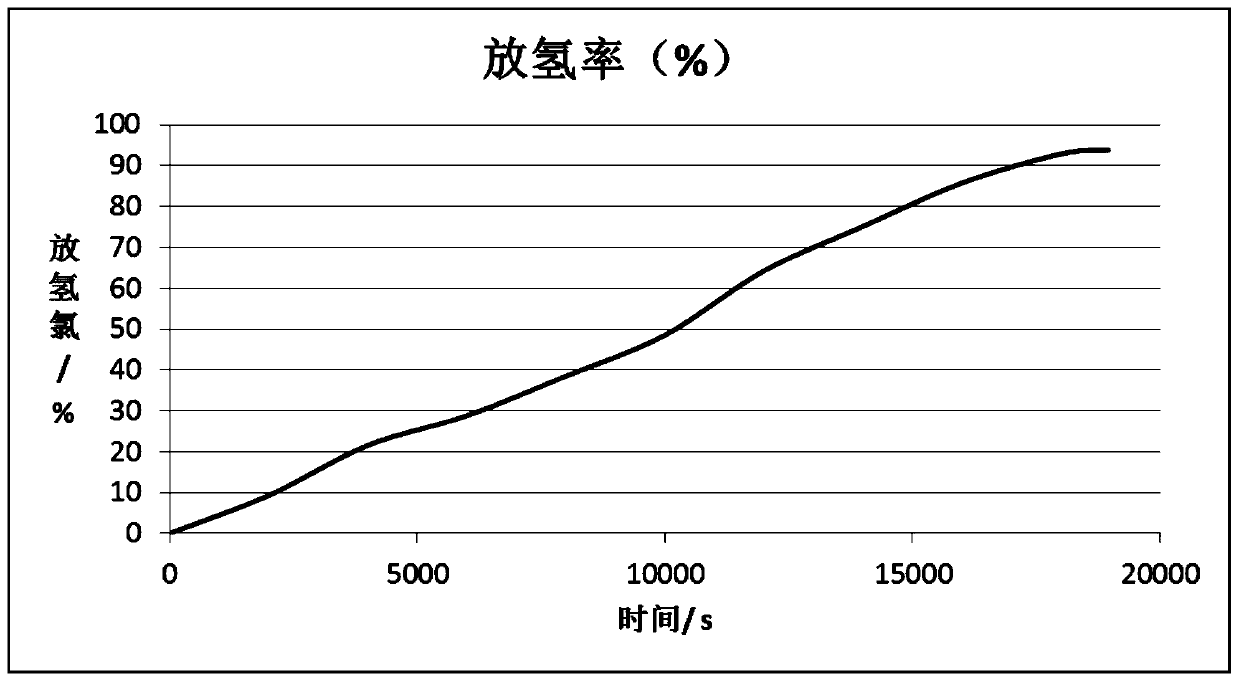

[0058] After the hydrogen production reaction starts, hydrogen can be collected within 1 min. After the reaction is completed, calculations after hydrogen collection show that the hydrogen production efficiency is above 90%.

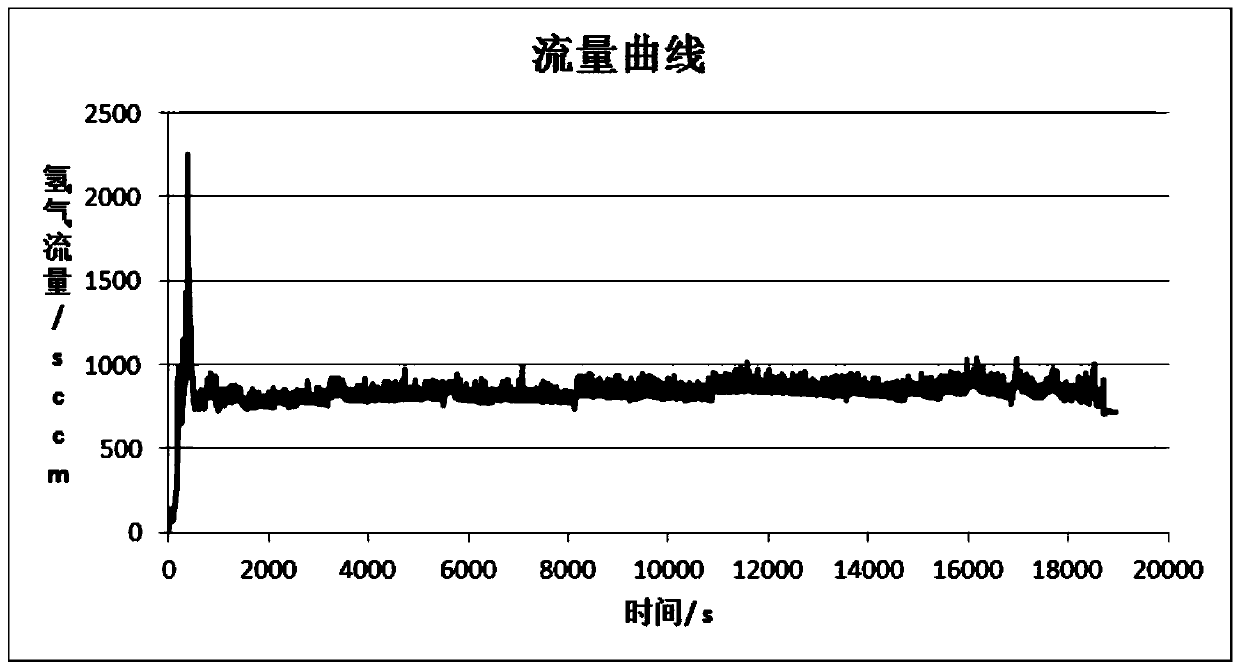

[0059] figure 1 The hydrogen release curve of the magnesium hydride quick start experiment prepared in this example, combined figure 1 Taking into account the system error caused by pipeline delay, hydrogen can be collected in a large amount and stably in about 1 minute after the start of pumping water, and the reaction is rapid.

[0060...

Embodiment 2

[0062] 1) In a glove box protected by nitrogen, mix magnesium hydride:X powder=1:0.2 according to the mass ratio, and then mechanically stir and mix uniformly to prepare reaction powder A.

[0063] 2) Put the reaction powder A in the reaction vessel, and start the hydrogen production reaction after the reaction powder A contacts the water vapor.

[0064] 3) The composition of X powder is CaCl 2 .

[0065] After the hydrogen production reaction starts, hydrogen can be collected within 2 minutes. After the reaction is completed, calculations after hydrogen collection show that the hydrogen production efficiency is above 88%.

Embodiment 3

[0067] 1) In a glove box protected by nitrogen, mix magnesium hydride:X powder=1:0.3 according to the mass ratio, and then mechanically stir and mix uniformly to prepare reaction powder A.

[0068] 2) Put the reaction powder A in the reaction vessel, and start the hydrogen production reaction after the reaction powder A contacts the liquid water.

[0069] 3) The composition of X powder is CuSO 4 .

[0070] After the hydrogen production reaction starts, hydrogen can be collected within 1 min. After the reaction is completed, calculations after hydrogen collection show that the hydrogen production efficiency is above 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com