Front-mounted integrated unit light-emitting diode

A technology of light-emitting diodes and integrated units, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor conductivity of p-type GaN materials, uneven current diffusion of chips, uneven current diffusion, etc., to improve light extraction. Efficiency, reduced lumen cost, improved lumen output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

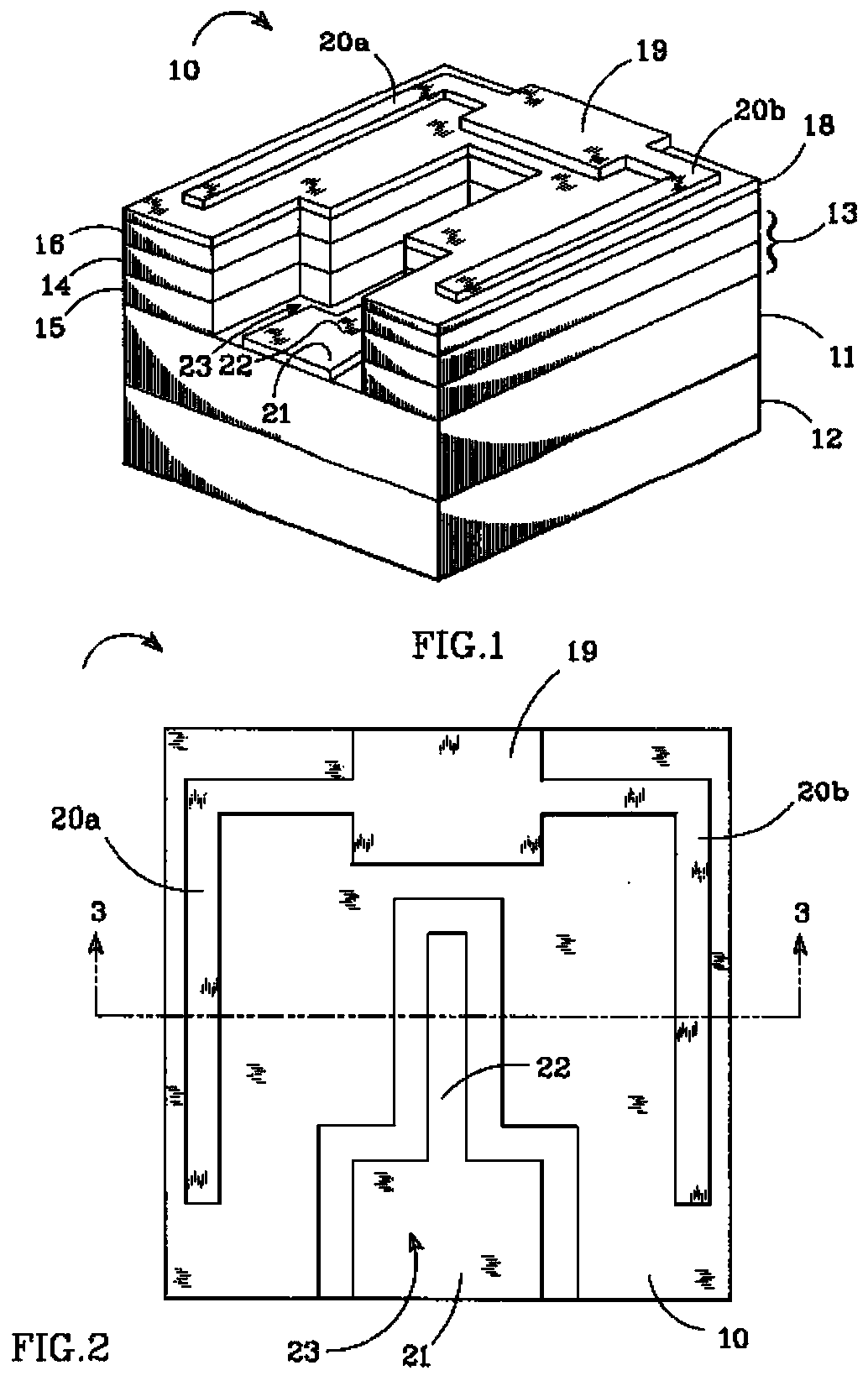

[0060] This embodiment provides a kind of integrated unit light-emitting diode, such as figure 2 shown, including:

[0061] The P-type electrode 1, the N-type electrode 2, the diode mesa structure 3, and the diode mesa structure 3 include 6 rows of 102 triangular diode units of equal size and uniform distribution.

[0062] Due to the high resistivity of indium tin oxide (ITO) and the poor electrical conductivity of the P-type GaN material itself, there is a problem of uneven current diffusion. This embodiment adopts the current diffusion method of ITO plus metal wires. In the front-mounted integrated unit light-emitting diode structure, the diode mesa structure is arranged in a triangle with a size of 0.1-200 microns, and the size of the mesa structure is smaller than the diffusion length of current injection. The electrode material adopts non-light-absorbing materials such as ITO / Al / Ag to improve light efficiency. The width of the finger line is 0.1-20 microns, and the thic...

Embodiment 2

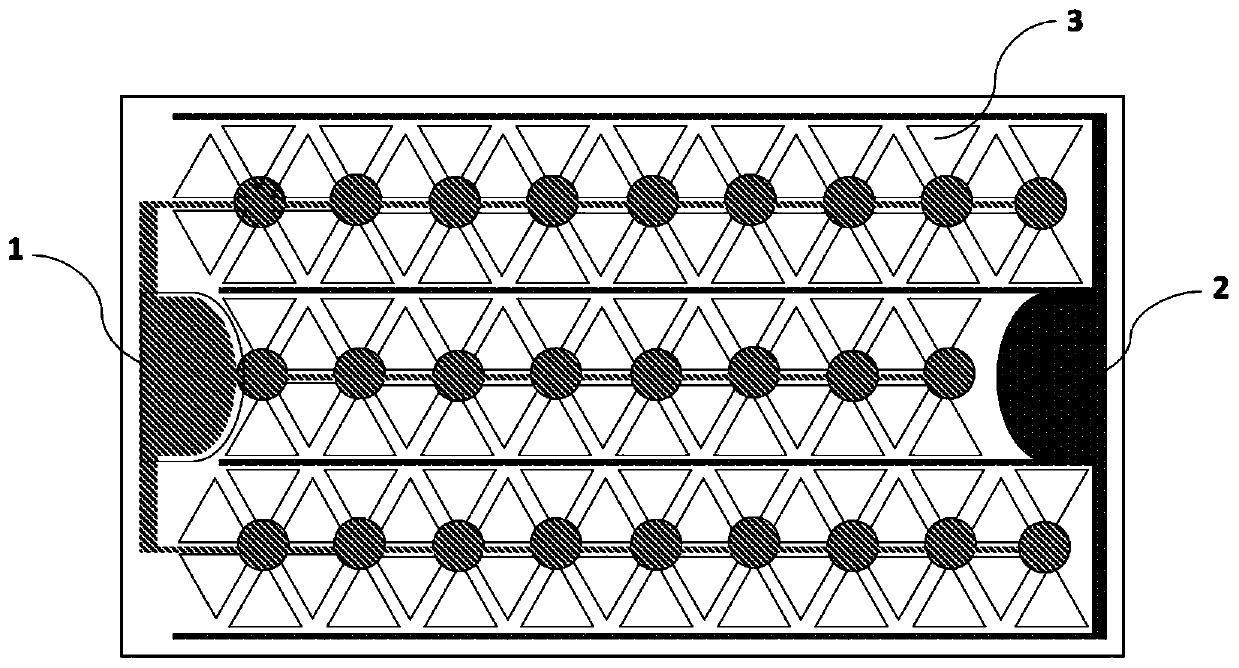

[0065] This embodiment provides a kind of integrated unit light-emitting diode, such as image 3 shown, including:

[0066] The P-type electrode 1, the N-type electrode 2, the diode mesa structure 3, and the diode mesa structure 3 include 6 rows of 52 square diode units of equal size and uniform distribution.

[0067] The diode mesa structure 3 adopts a square diode unit arrangement with a length of 0.1-200 microns. In order to have better current diffusion performance, the length of the mesa structure is smaller than the diffusion length of current injection. The electrode material adopts non-light-absorbing materials such as ITO / Al / Ag to improve light efficiency. The width of the finger line is 0.1-20 microns, and the thickness is 0.1-10 microns.

[0068] This design structure can obtain the best current diffusion and heat dissipation performance under the specified working current, and greatly improve the injection current density of the chip, thereby increasing the lumen ...

Embodiment 3

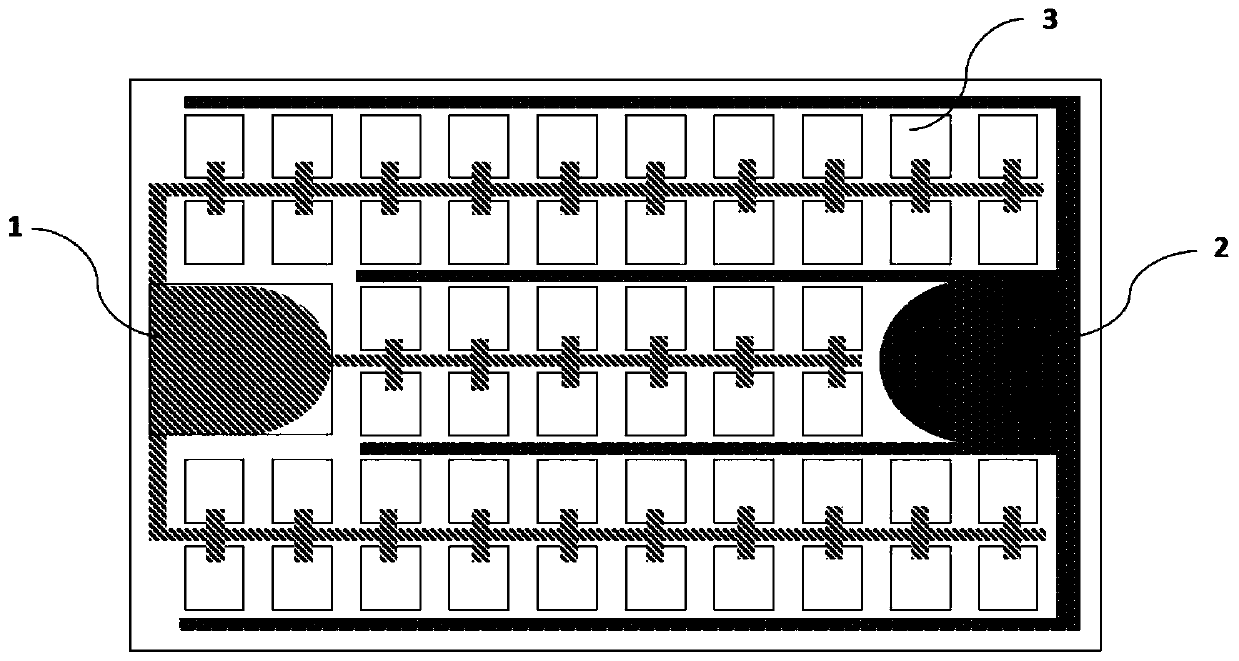

[0070] This embodiment provides a kind of integrated unit light-emitting diode, such as Figure 4 shown, including:

[0071] The P-type electrode 1, the N-type electrode 2, the diode mesa structure 3, and the diode mesa structure 3 include 6 rows of 6 uniformly distributed rectangular diode units of unequal size.

[0072] The diode mesa structure 3 adopts a rectangular diode unit arrangement, and the length of the narrowest part of the rectangle is 0.1-200 microns. In order to have better current diffusion performance, the length of the mesa structure is smaller than the diffusion length of current injection. This design structure can obtain the best current diffusion and heat dissipation performance under the specified working current, and greatly improve the injection current density of the chip, thereby increasing the lumen output per unit area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com