Thin film packaged LED display array module

A display array and thin film packaging technology, applied in identification devices, instruments, etc., can solve problems such as affecting production efficiency and display effect, poor module ink color consistency, crosstalk of light-emitting pixels, etc., to achieve good color consistency, simple production process, The effect of a large viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An LED display array module arranged in a dot matrix with a dot pitch of d=1.25mm and a resolution of 64×64.

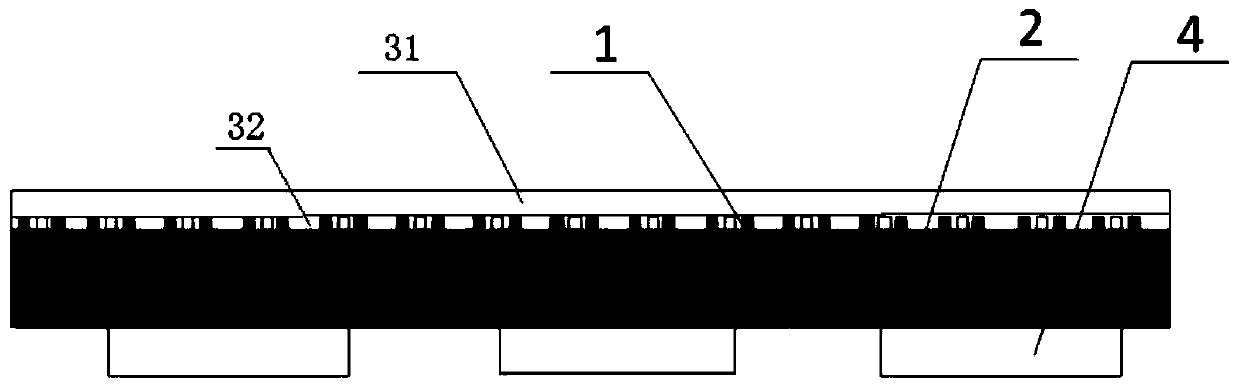

[0026] Such as figure 1 , 2 As shown, the film-encapsulated LED display array module of the present invention is formed by splicing a plurality of LED display modules, and the LED display module includes a driver IC4, a display substrate 2, an LED wafer 1 and a layer of film 31, and the film 31 The thickness is 0.1-0.8mm. The driver IC 4 is welded on the rear surface of the display substrate 2 , the LED chip 1 is fixed on the front surface of the display substrate 2 , and the film 31 is pasted on the front surface of the display substrate. The film 31 is made of epoxy resin; the LED wafer 1 is an ordinary red, green and blue LED light-emitting chip; the display substrate 2 is a printed circuit board PCB.

[0027] The film 31 is encapsulated on the front surface of the display substrate 2 by the following method: first, a layer of buffer glue 32 is sprayed on...

Embodiment 2

[0031] An LED display array module with a dot pitch of d=1.25mm and a dot matrix with a resolution of 64×64.

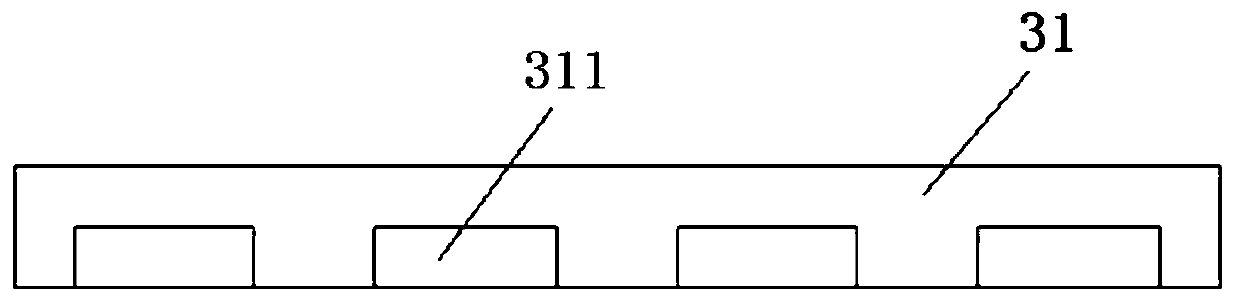

[0032] Such as image 3 , 4 , 5, the film-encapsulated LED display array module of the present invention is spliced by a plurality of LED display modules, and the LED display module includes a driver IC4, a display substrate 2, an LED wafer 1 and a layer of film 31, and the film 31 has a thickness of 0.1-0.8mm; the back of the film 31 has a hole 311 corresponding to the position of the LED chip; the driver IC 4 is welded on the rear surface of the display substrate 2, the LED chip 1 is fixed on the front surface of the display substrate 2, and the film 31 is packaged on the front surface of the display substrate 2 . The film 31 is made of epoxy resin; the LED wafer 1 is an ordinary red, green and blue LED light-emitting chip; the display substrate 2 is a printed circuit board PCB.

[0033] The film 31 is encapsulated on the front surface of the display substrate ...

Embodiment 3

[0037] Such as Figure 6 , 7 , 8, the film-encapsulated LED display array module of the present invention is spliced by a plurality of LED display modules, and the LED display module includes a driver IC4, a display substrate 2, an LED wafer 1 and two layers of films, the first The thickness of the first layer of film 33 is 0.1 mm, and the thickness of the second layer of film 34 is 0.3 mm; the first layer of film 33 is black, and has a through hole 331 corresponding to the LED wafer 1; the driver IC4 is welded behind the display substrate 2 On the surface, the LED chip 1 is fixed on the front surface of the display substrate 2 , the first film 33 is packaged on the front surface of the display substrate 2 , and the second film 34 is pasted on the front surface of the first film 33 . The materials of the two layers of film are epoxy resin; the LED chip 1 is a common red, green and blue LED light-emitting chip; the display substrate 2 is a printed circuit board PCB.

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com