Rocket ejector and thermal protection structure and method thereof

A technology for thermal protection structure and ejection of rockets, which is applied in the direction of rocket engine devices, jet propulsion devices, ramjet engines, etc., can solve the problems of insufficient cooling of the throat, and achieve good cooling effect, less coolant, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand this technology, we will further describe the present invention in detail in conjunction with the accompanying drawings and specific implementation examples.

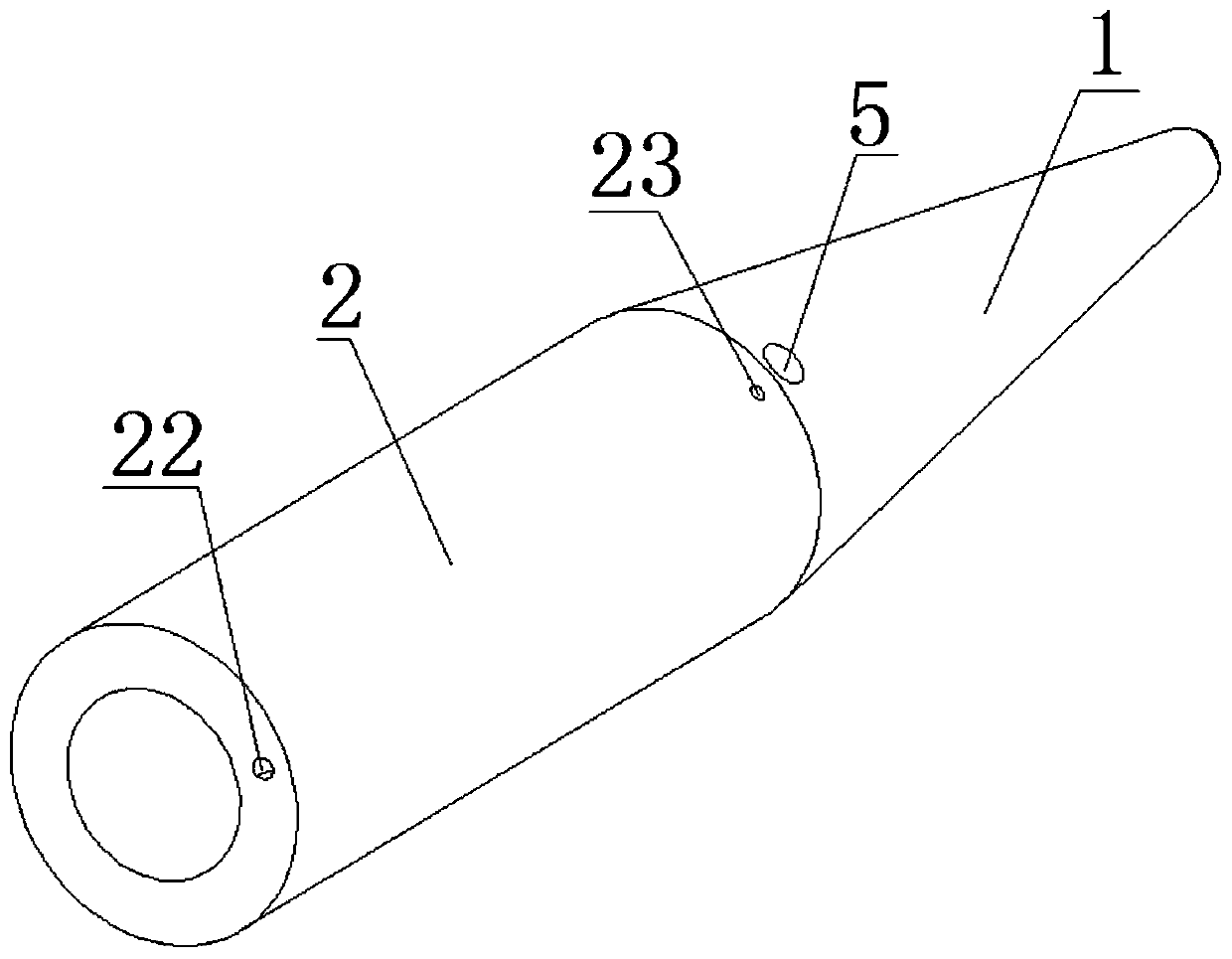

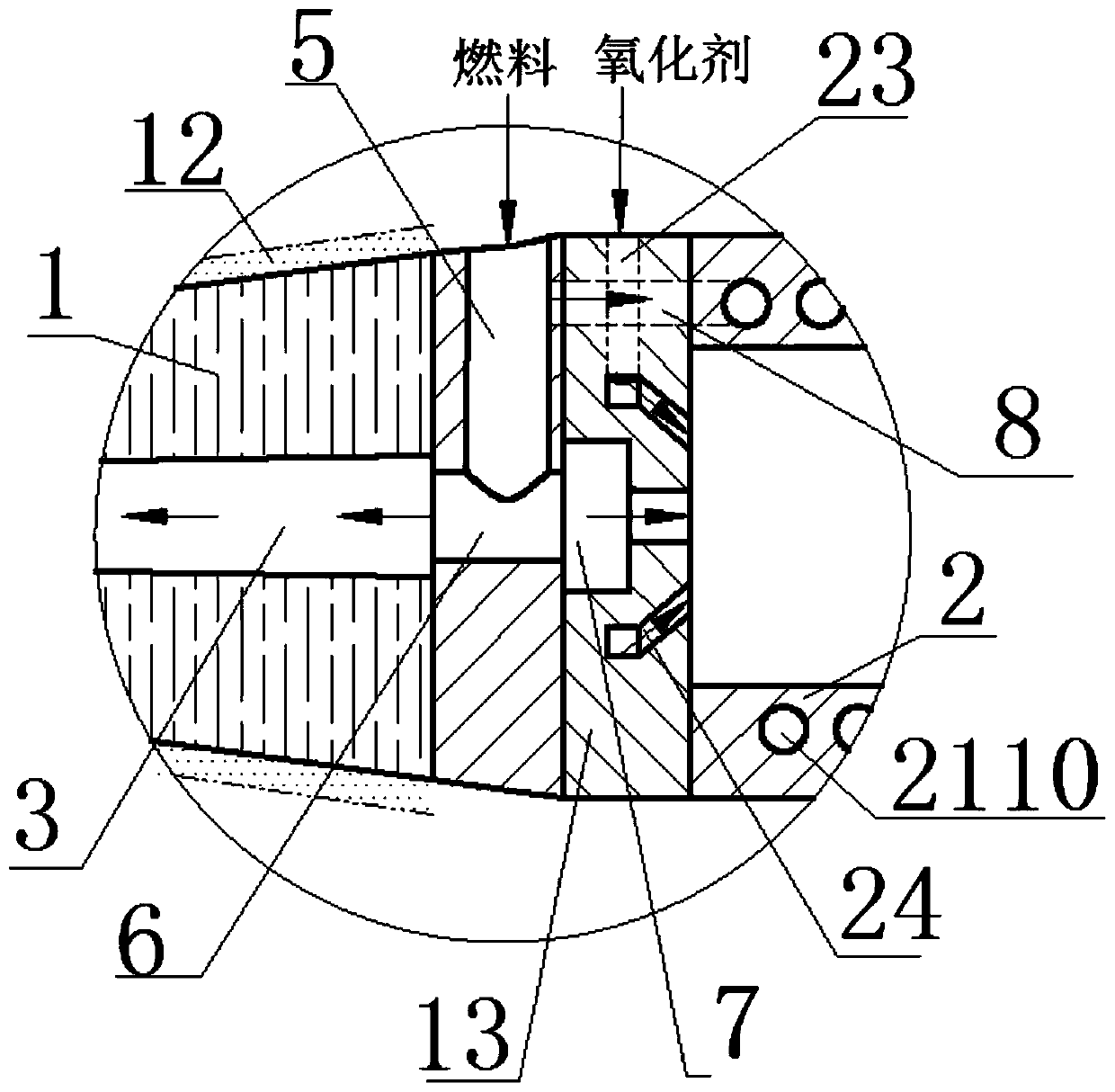

[0035] The embodiment of the present invention provides a heat protection structure for a TRRE ejection rocket using exhaust and sweat compound cooling. The TRRE ejection rocket includes a leading edge nose cone 1 and a thrust chamber 2, and the thrust chamber 2 includes a combustion chamber 20 and a thrust chamber 2. Nozzle 21, the nozzle 21 is divided into a nozzle inner layer 210 and a nozzle outer layer 211; the thermal protection structure includes a sweat cooling structure and a discharge cooling structure, and the sweat cooling structure includes a laminate sweat cooling structure and a porous sweat cooling structure Cooling structure: the front nose cone 1 adopts a laminar sweating cooling structure, the combustion chamber 20 and the nozzle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com