Novel cable and method for relieving ablation of cable buffer layer

A buffer layer and conductive buffer technology, applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., to achieve the effects of stable physical and chemical properties, good electrical conductivity, and reduced insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] like figure 1 As shown, a conductive solution is filled between the aluminum sheath 1 and the insulating shielding layer 2 of the XLPE cable with a voltage level of 220kV. A semi-conductive buffer strip 4 is also included, and the semi-conductive buffer strip 3 is placed on the insulating shielding layer 2 .

[0035] A conductive liquid is injected into the XLPE cable with a voltage level of 220kV, and the electrical parameters of the conductive liquid are shown in Table 1:

[0036] Table 1 Electrical parameters of conductive liquid

[0037] Relative permittivity 100 Thermal conductivity / W·(m·K) -1

Embodiment 2

[0039] A conductive liquid is injected into the XLPE cable with a voltage level of 220kV, and the electrical parameters of the conductive liquid are shown in Table 2:

[0040] Table 2 Electrical parameters of conductive liquid

[0041] Relative permittivity 100 Thermal conductivity / W·(m·K) -1

0.29 Constant pressure heat capacity J / (kg·K) 2120 Conductivity S / m 10 -3 -10 -12

pH 7.0 toxicity toxic free and safe

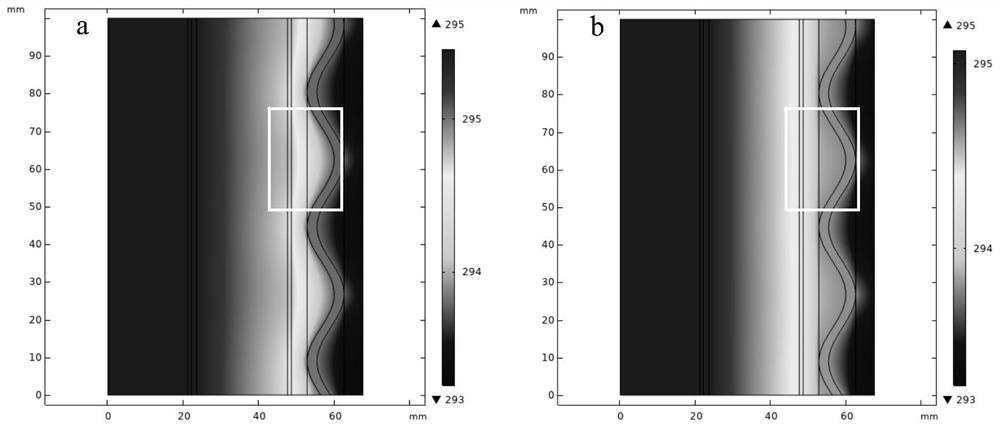

[0042] Figure 8 In Example 2, the electrical conductivity was decreased by 10 times from 0.001S / m to 1e -12 S / m (conductivity in turn: 1×10 -3 S / m, 1×10 -4 S / m, 1×10 -5 S / m, 1×10 -6 S / m, 1×10 -7 S / m, 1×10 -8 S / m, 1×10 -9 S / m, 1×10 -10 S / m, 1×10 -11 S / m), the current density distribution diagram when white powder appears in the aluminum sheath and buffer layer. It can be seen from the figure that when the conductivity is 0.001S / m, the current density is the most uniform, 1×10 -11 most uneven time. For furth...

Embodiment 3

[0048] A conductive liquid is injected into the XLPE cable with a voltage level of 220kV, and the electrical parameters of the conductive liquid are shown in Table 3:

[0049] Table 3 Electrical parameters of conductive liquid

[0050] Relative permittivity 1-5000 Thermal conductivity / W·(m·K) -1

0.29 Constant pressure heat capacity J / (kg·K) 2120 Conductivity S / m 10 -6

pH 7.0 toxicity toxic free and safe

[0051] Figure 12 For example 3, the relative dielectric constant is 1-5000 (the values are 1, 10, 50, 100, 200, 1000, 3000, 4000, 5000), and the current density distribution diagram when white powder appears in the aluminum sheath and buffer layer , Figure 13 for different relative permittivity Figure 12 It can be seen from the figure that when the relative permittivity increases, the current density on the main insulation increases, but the maximum current density decreases. Depend on Figure 12 and Figure 13 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com