Vacuum tube type steam sterilizer and sterilization method thereof

A steam sterilization, vacuum tube technology, applied in sanitary equipment, water supply devices, heating and other directions for toilets, can solve the problems of contamination of the working medium of the sealing rubber pad, slow heat transfer, short continuous working time, etc., to avoid the rubber pad Failure problems, effects of long working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

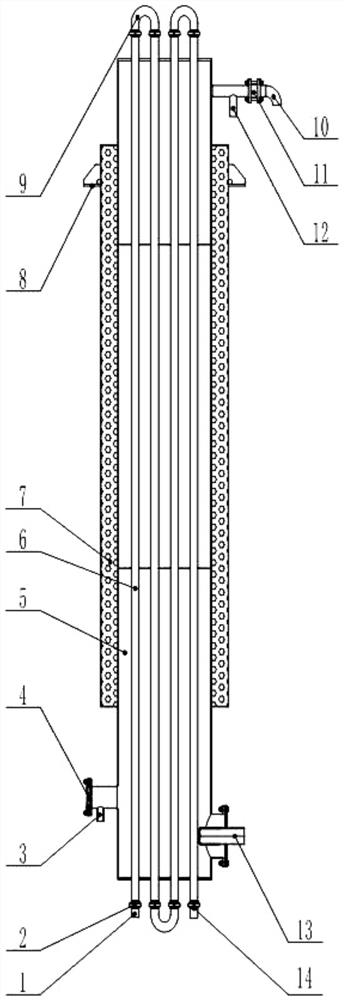

[0028] This embodiment discloses a vacuum tube type steam sterilizer as shown in 1, which includes a feed port 1, a discharge port 14, a pressure joint 2, a drain port 3, a sight glass 4, a sterilizer liner 5, a material Pipe 6, sterilizer insulation layer 7, support 8, 180° elbow 9, exhaust port 10, one-way valve 11, vacuum port 12 and steam inlet assembly 13.

[0029] The sterilizer of this embodiment is cylindrical as a whole, placed vertically, and fixed on the frame, platform or floor through the support 8. The shape of the support 8 is not fixed, and the quantity changes according to the demand. The support 8 is usually welded on the outer side of the insulation layer 7 of the sterilizer for fixing the sterilizer.

[0030] The inner side of the heat preservation layer 7 of the sterilizer in this embodiment is rock wool, and the thickness of the rock wool is determined according to actual needs. The outermost side is covered with a 304 stainless steel plate. 5 A certain...

Embodiment 2

[0037] This embodiment discloses the use of a vacuum tube type steam sterilizer. The material enters the S-shaped material tube 6 from the feed port 1 at a certain speed through the front-end conveying pump, and is discharged from the discharge port 14 . The sterilizer enters the initial debugging stage, and the vacuum pump connected to the vacuum port 12 is started, so that a certain degree of vacuum is maintained in the inner tank 5 of the sterilizer. Steam is sprayed into the sterilizer liner 5 through the steam inlet assembly 13 . Since the overall temperature of the sterilizer is still relatively low, the steam quickly condenses into water. After the steam is continuously injected for a period of time, the temperature in the inner tank 5 of the sterilizer is slightly improved.

[0038] The steam is sprayed into the sterilizer liner 5 through the steam inlet assembly 13, and exchanges heat with water. Since the inner tank 5 of the sterilizer maintains a certain degree of...

Embodiment 3

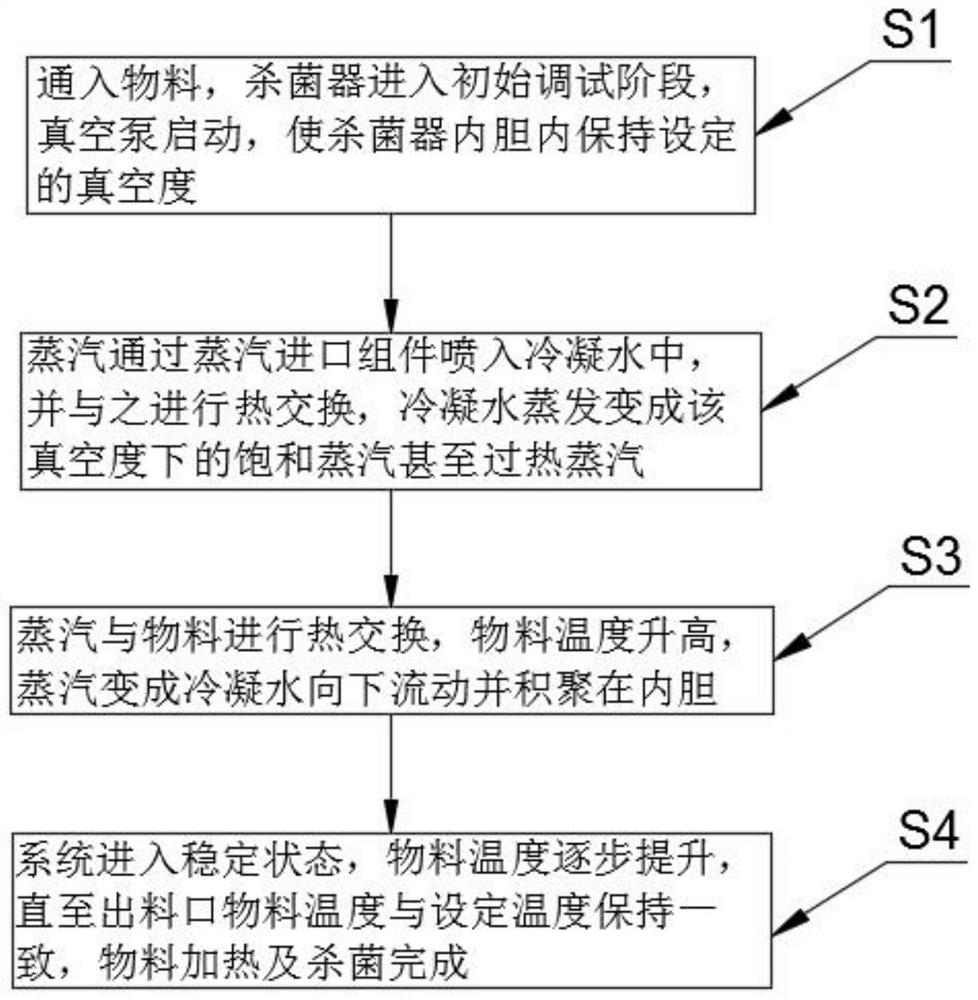

[0043] This embodiment discloses as figure 2 A sterilizing method of a vacuum tube type steam sterilizer shown comprises the following steps:

[0044] S1 feeds the material, the sterilizer enters the initial debugging stage, and the vacuum pump starts to keep the set vacuum degree in the inner tank of the sterilizer;

[0045] S2 steam enters the condensed water through the blind pipe of the steam inlet component and exchanges heat with it, and the water evaporates to become saturated steam under the vacuum degree;

[0046] S3 steam exchanges heat with the material, the temperature of the material rises, and the steam becomes condensed water and accumulates in the inner tank;

[0047] The S4 system enters a stable state, and the temperature of the material is gradually increased until the temperature of the material at the discharge port is consistent with the set temperature, and the heating and sterilization of the material are completed.

[0048] In this embodiment, a par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com