Brake drum water-spraying method, auxiliary system and vehicle

A technology of auxiliary system and brake drum, applied in the direction of brakes, vehicle components, cooling brakes, etc., can solve the problems of inability to meet cooling needs, poor versatility, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

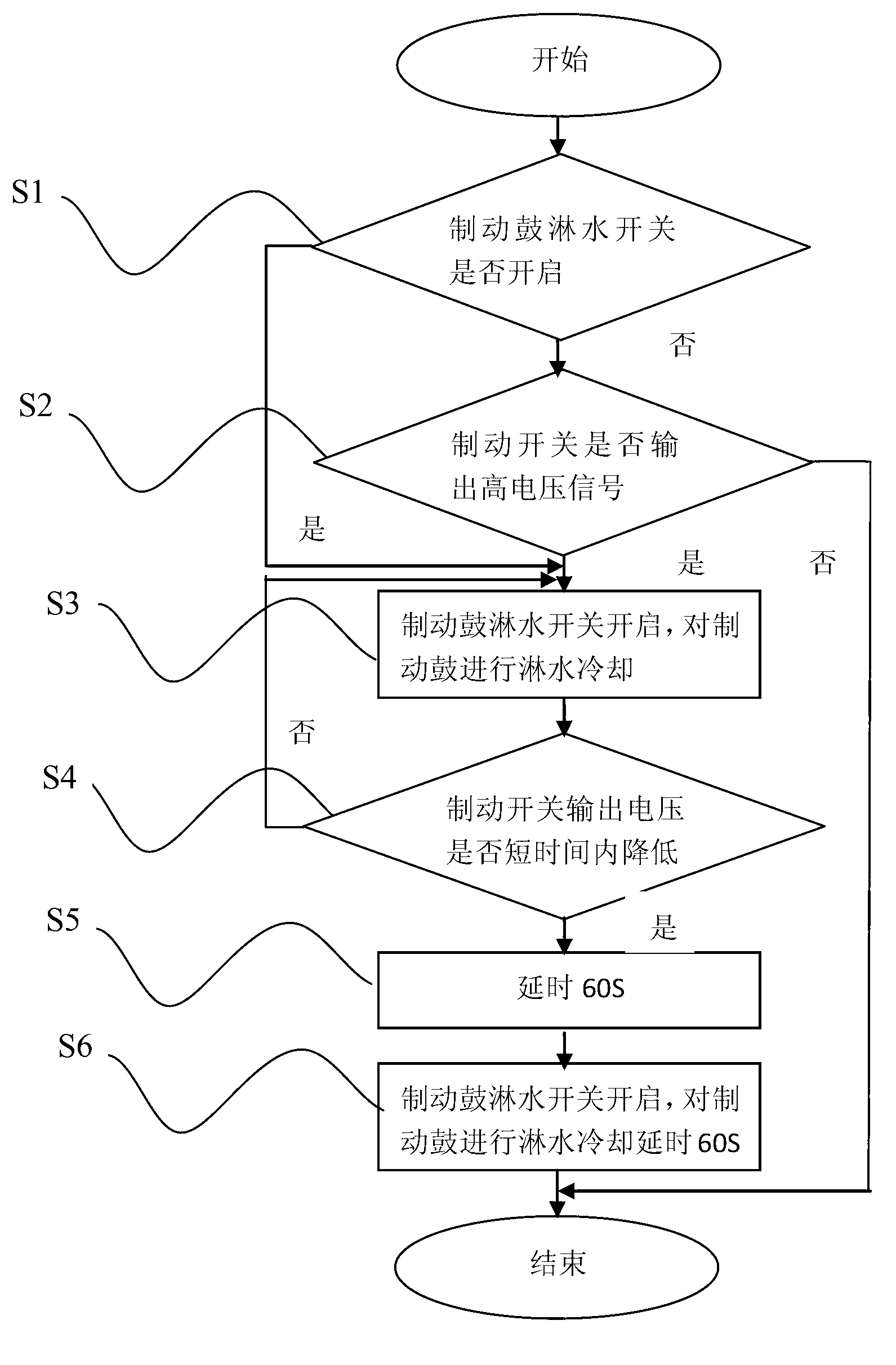

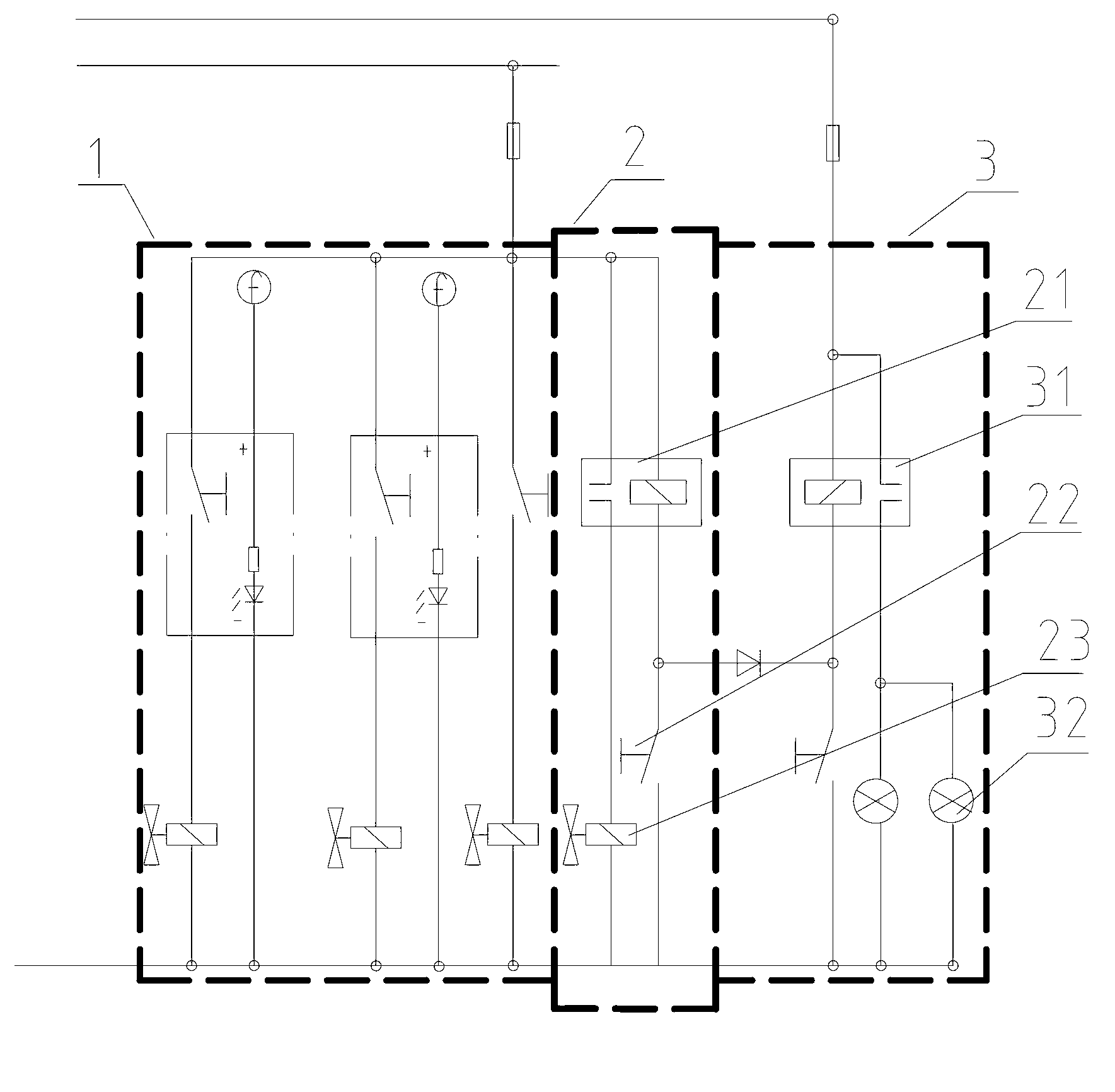

[0036] like figure 1 and figure 2 As shown, the flow process of the brake drum spraying method is carried out through the following steps:

[0037] Step S1: After the car is started, it is judged whether the water spray switch is turned on, if yes, go to step S3; if not, go to step S2;

[0038] Step S2: Determine whether the brake switch outputs a high-voltage signal, that is, whether the brake switch is performing service braking. When the vehicle is performing service brake, the brake switch is turned on, and high voltage is output at both ends. If yes, proceed to step S3; if not, end the brake drum water spray cooling;

[0039] Step S3: The brake drum water spray device is turned on, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com