Method for secondarily cooling and molding strip and device thereof

A secondary cooling and refrigeration device technology, applied in the cooling field, can solve the problem of high strip temperature, reduce the coiling temperature, save production, and solve the effect of insufficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

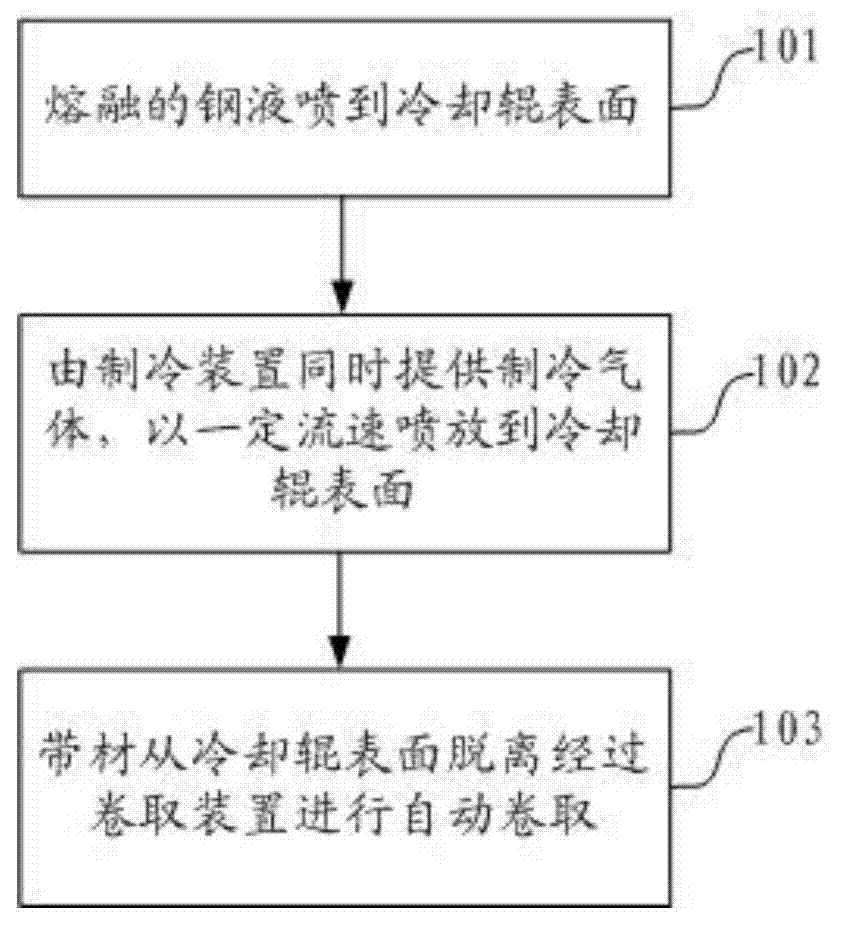

Method used

Image

Examples

example 1

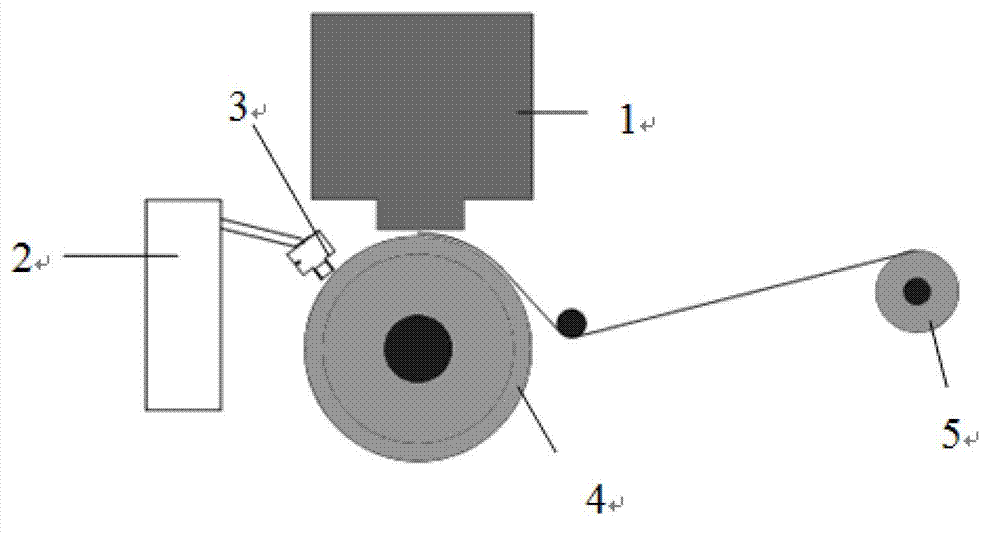

[0029] Example 1: When the molten steel is sprayed onto the surface of the cooling roll, the cooling gas is provided by the liquid nitrogen device, and the liquid nitrogen is sprayed onto the surface of the cooling roll through the liquid nitrogen nozzle at a flow rate of 8ml / min, and finally the strip is cooled from The surface of the roll is detached and passed through the coiling device for automatic coiling.

[0030] The temperature after coiling is 130 degrees, and the magnetic properties after heat treatment are as follows: under the conditions of 1.35T and 50Hz, the unit iron loss is 0.142W / Kg, showing good magnetic properties.

example 2

[0031] Example 2: When the molten steel is sprayed onto the surface of the cooling roller, the device for storing dry ice will provide refrigeration gas, and the dry ice will be sprayed onto the surface of the cooling roller through the nozzle of the device for storing dry ice at a flow rate of 10ml / min, and finally brought The material is detached from the surface of the cooling roll and passed through the coiling device for automatic coiling.

[0032] The temperature after coiling is 135 degrees, and the magnetic properties after heat treatment are as follows: under the conditions of 1.35T and 50Hz, the unit iron loss is 0.153W / Kg, showing good magnetic properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com