Clear water template trolley for constructing side wall structure in shield tunnel

A technology of side wall structure and clear water formwork, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as low construction efficiency, poor safety performance, and difficult linear control, so as to improve construction efficiency, avoid material loss, reduce The effect of a small workforce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

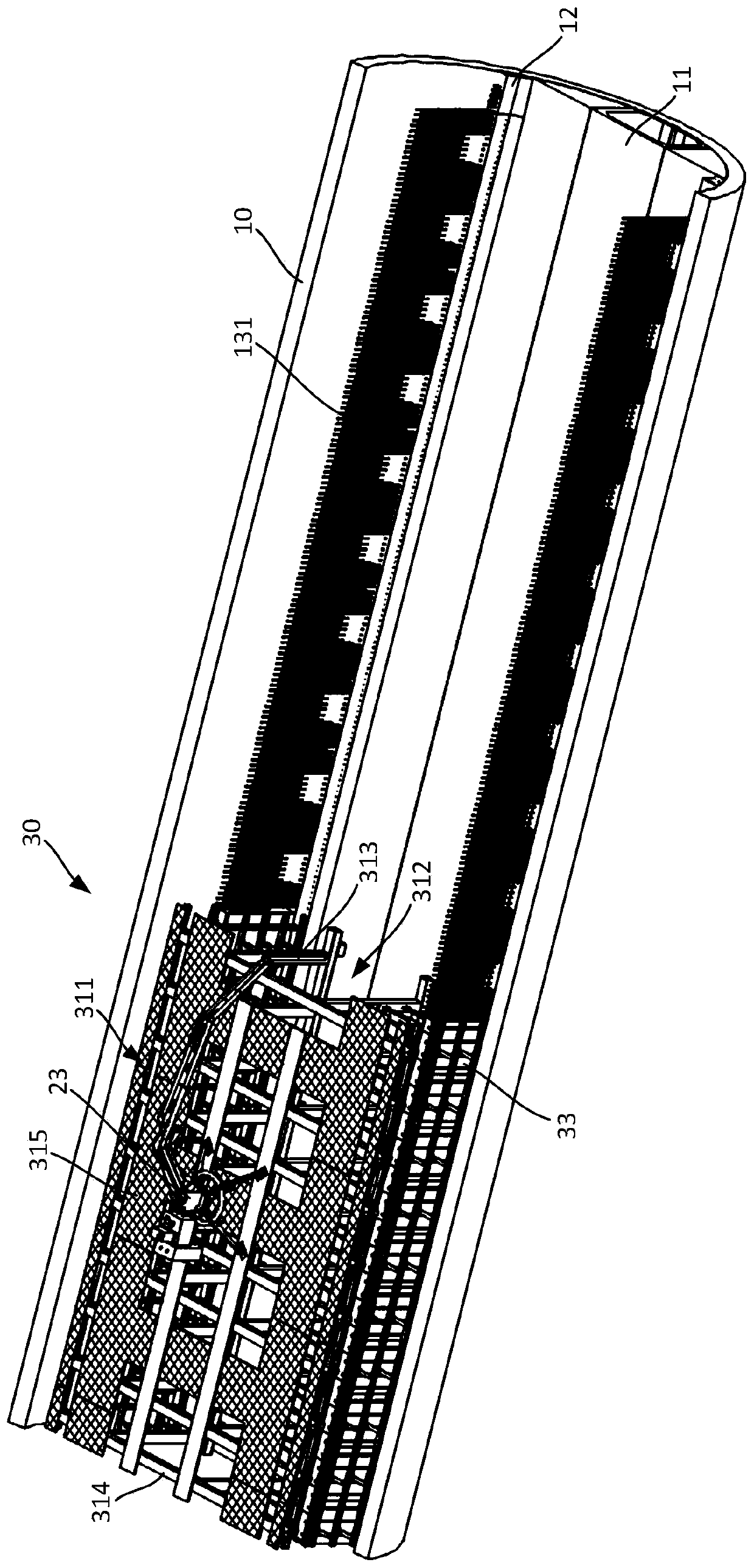

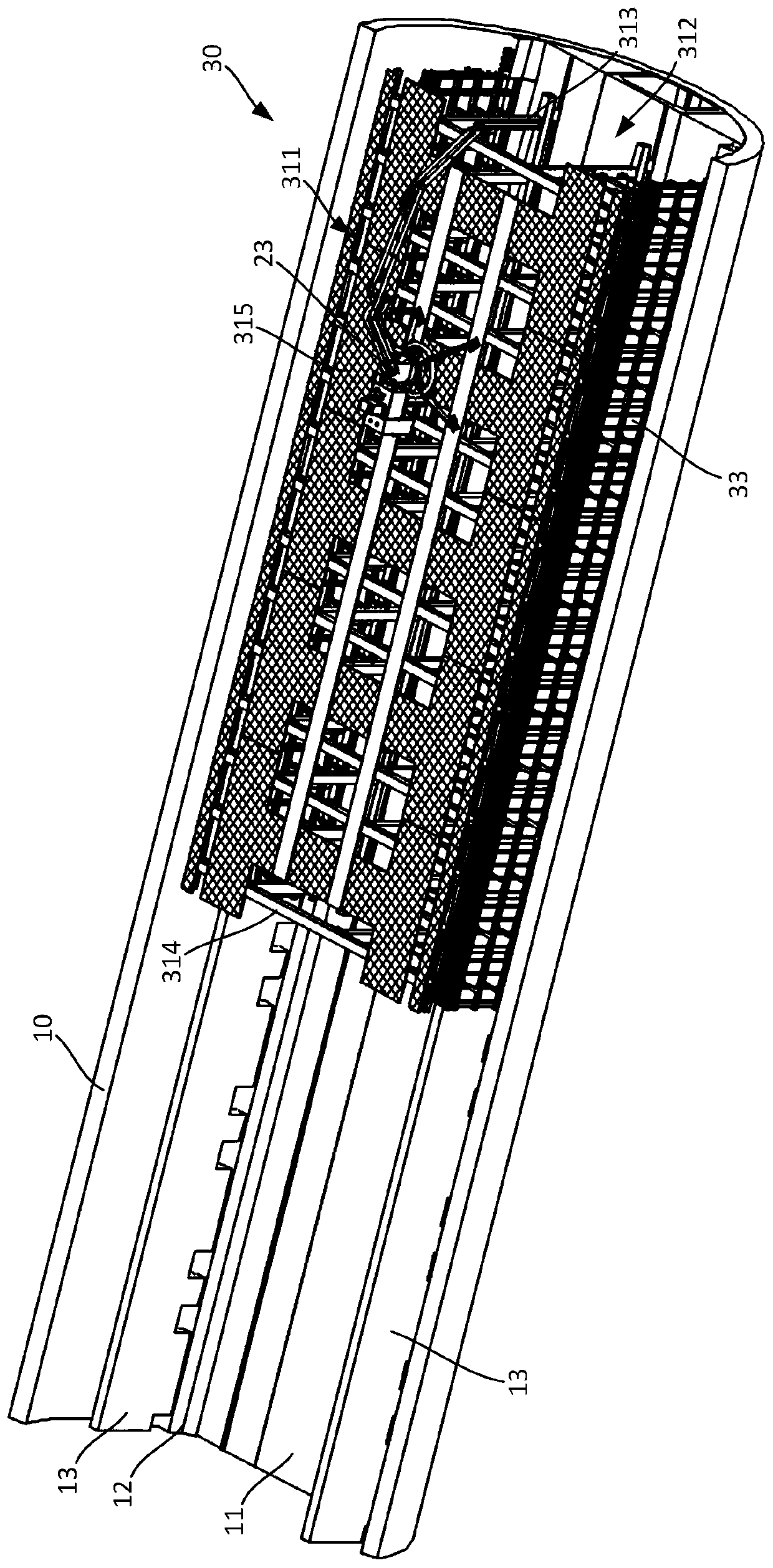

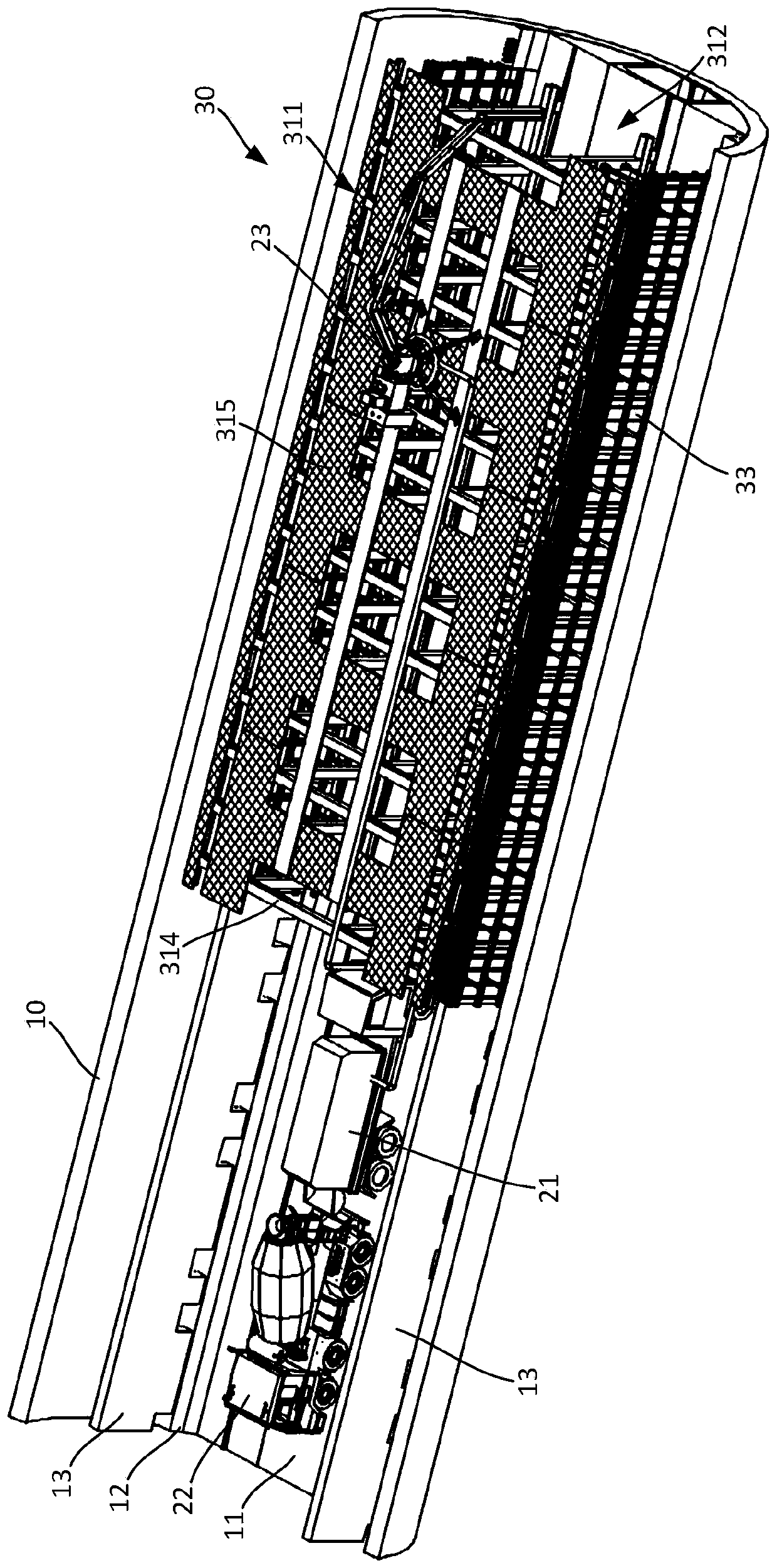

[0041] refer to figure 1, The invention provides a clear water formwork trolley used for constructing the inner side wall structure of a shield tunnel. Considering the overall architectural effect of the circular tunnel and the particularity of traffic safety, in the double-layered tunnel excavated with a 15.56m-diameter ultra-large mud-water-air balance shield, the decorative environment of the tunnel is omitted, and the facing fair-faced concrete is introduced into the lower layer of the internal structure In the side walls on both sides of the driveway, the clear-water formwork trolley cooperates with the distributing machine to form a complete construction equipment system to realize the pouring construction of the clear-water concrete side walls. The clear water formwork trolley of the present invention utilizes the principle of steel str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com