Graphene oxide composite hydroxyapatite-loaded sulfur quantum dot antibacterial coating and preparation method thereof

A composite hydroxyapatite and antibacterial coating technology, applied in coatings, antifouling/underwater coatings, paints containing biocides, etc. , to quickly and effectively kill bacteria, the preparation method is simple and easy, and the effect of increasing the production of active oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Also provided is a preparation method of graphene oxide composite hydroxyapatite-loaded sulfur quantum dot antibacterial coating, comprising the following steps:

[0040] S1. Pretreatment of titanium sheets: Polish the titanium sheets with 240, 400, 600, 800 and 1200 mesh sandpaper in sequence, then ultrasonically clean them with water and ethanol, and then put the titanium sheets into a mixed solution of concentrated sulfuric acid, concentrated hydrochloric acid and water In the process, after heating and reacting in a polytetrafluoroethylene reactor, it is taken out and cleaned, and then calcined in a muffle furnace;

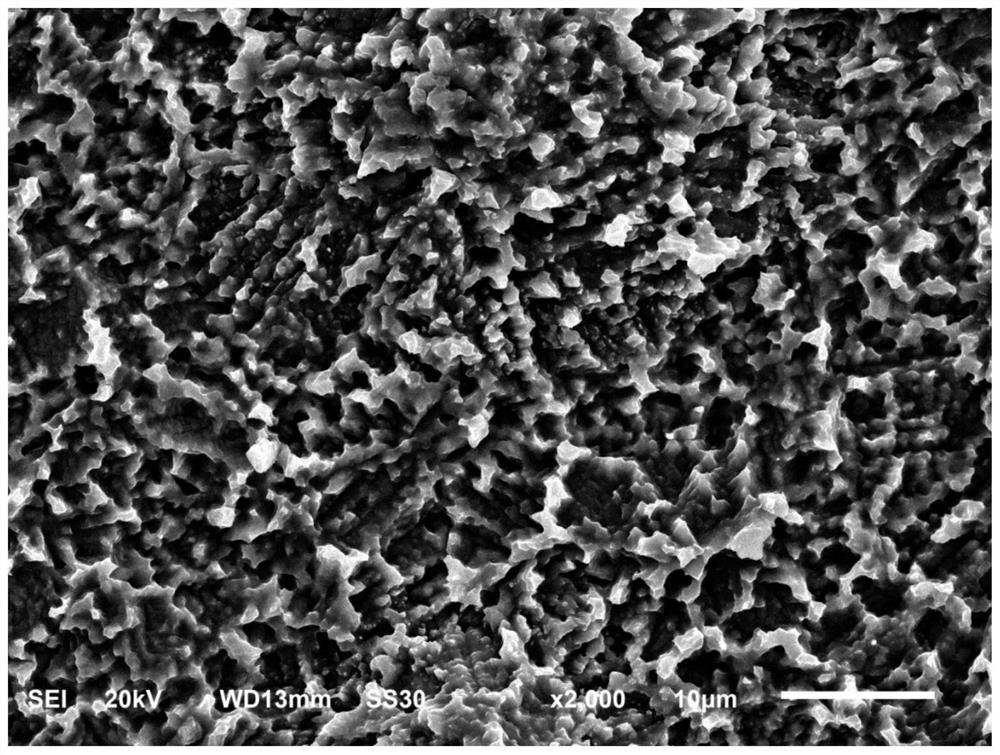

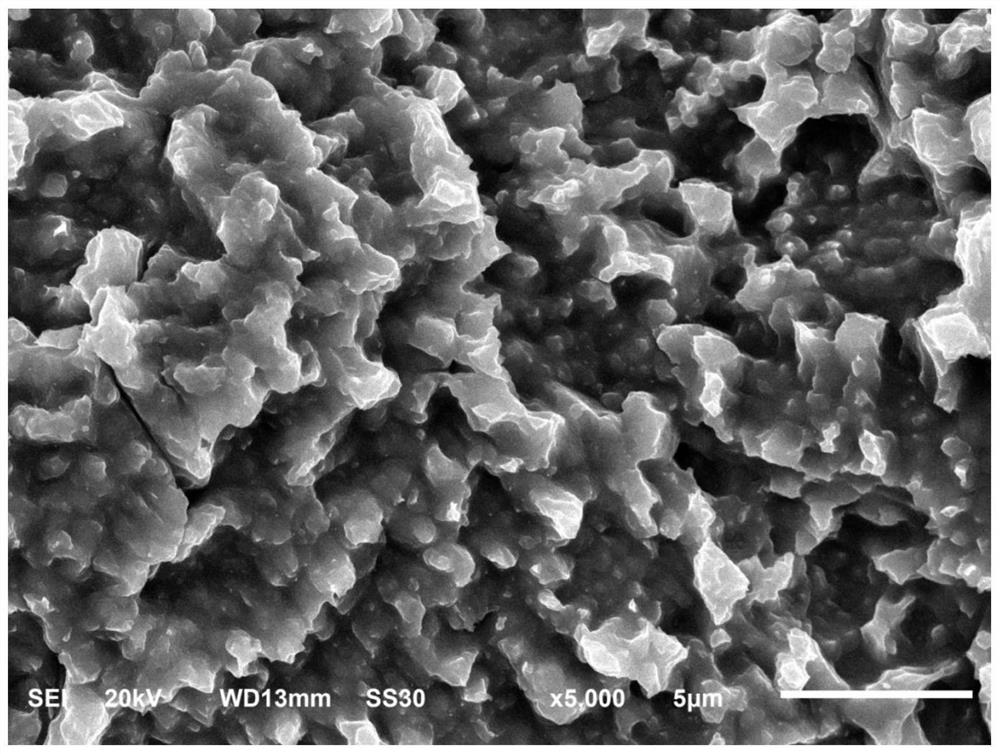

[0041] S2. Preparation of graphene oxide composite hydroxyapatite coating: Add disodium edetate powder to calcium nitrate solution, mix evenly to obtain mixed solution A, mix mixed solution A with diammonium hydrogen phosphate solution in the same volume, Adjust the pH to 8.7-10.5, add the graphene oxide solution, stir well to obtain the mixed solution ...

Embodiment 1

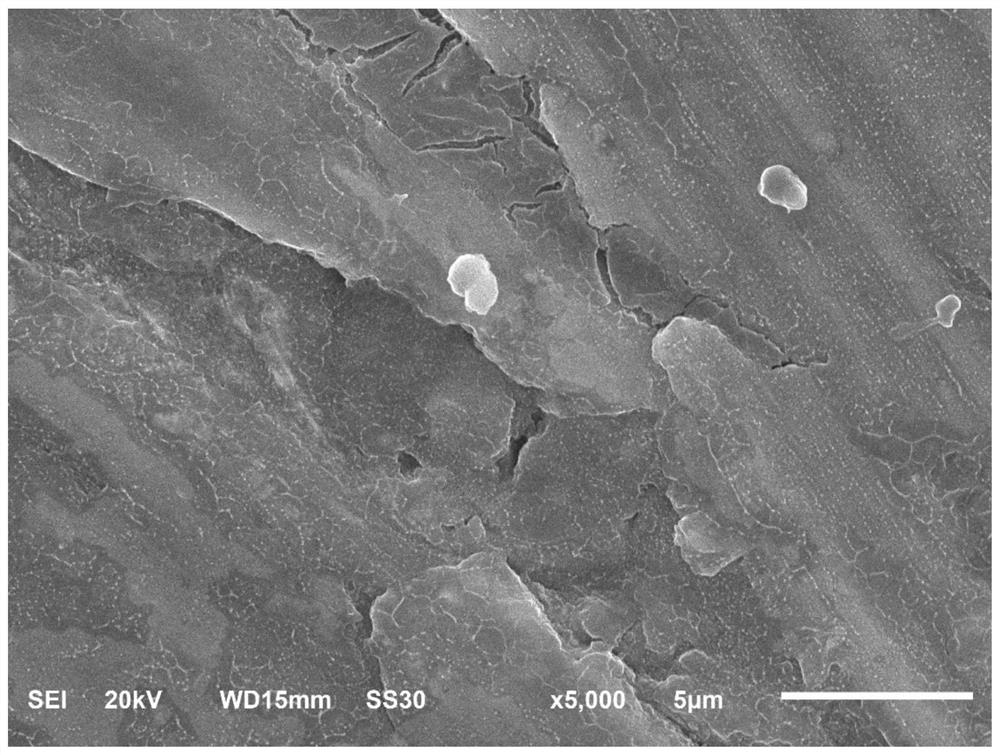

[0051] (1) Pretreatment of titanium sheets: First, polish the titanium sheets with 240, 400, 600, 800, and 1200 mesh sandpaper, then ultrasonically clean them with water and ethanol, and add concentrated sulfuric acid to the titanium sheets: Concentrated hydrochloric acid: The mass ratio of water In a mixed solution of 1:1:1, react in a polytetrafluoroethylene reactor at 60°C for 1.5h, take out the titanium sheet for cleaning, and then calcinate in a muffle furnace at 650°C for 1h to obtain a pretreated titanium sheet.

[0052] (2) Preparation of graphene oxide composite hydroxyapatite coating: add 2g of disodium edetate powder to 30mL of 0.2mol / L calcium nitrate solution, mix evenly to obtain mixed solution A, and then configure 0.12mol / L L of diammonium hydrogen phosphate solution, mix 30mL of mixed solution A with 30mL of diammonium hydrogen phosphate solution in the same volume, adjust the pH to 10.5, add 2mg / mL graphene oxide 10mL, after fully stirring, and step (1) The o...

Embodiment 2

[0056] (1) Pretreatment of titanium sheets: First, polish the titanium sheets with 240, 400, 600, 800, and 1200 mesh sandpaper, then ultrasonically clean them with water and ethanol, and add concentrated sulfuric acid to the titanium sheets: Concentrated hydrochloric acid: The mass ratio of water In a mixed solution of 1:1:1, react in a polytetrafluoroethylene reactor at 70°C for 1 hour, take out the titanium sheet for cleaning, and then calcinate it in a muffle furnace at 600°C for 1.5 hours to obtain a pretreated titanium sheet.

[0057] (2) Preparation of graphene oxide composite hydroxyapatite coating: add 2g of disodium edetate powder to 30mL of 0.2mol / L calcium nitrate solution, mix evenly to obtain mixed solution A, and then configure 0.12mol / L L of diammonium hydrogen phosphate solution, mix 30mL of mixed solution A with 30mL of diammonium hydrogen phosphate solution in the same volume, adjust the pH to 9.5, add 1mg / mL graphene oxide 10mL, after fully stirring, and step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com