A distiller's grain extract and its preparation method and application

A technology for extract and distiller's grains, which is applied in the field of preparation of liquor distiller's grains extract, can solve the problems of low utilization rate of distiller's grains extract and the like, achieves prevention of harm to human body, easy industrial application, good inhibition of carboxymethyl lysine production the effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of filler for extracting distiller's grain antioxidant components

[0039] 1. Experimental materials and instruments

[0040] Gallic acid: Shanghai Tian Biotechnology Co., Ltd.; 4-vinylpyridine, ethylene glycol dimethacrylate, azobisisobutyronitrile: Shanghai McLean Biochemical Technology Co., Ltd.; trioctylphosphine modified CdSe / ZnS quantum Dot: Wuhan Jiayuan Quantum Dot Technology Development Co., Ltd.; Methanol: Sinopharm Chemical Reagent Co., Ltd.; Acetone: Sinopharm Chemical Reagent Co., Ltd.; Acetonitrile: Sinopharm Chemical Reagent Co., Ltd.; Xylene: Sinopharm Chemical Reagent Co., Ltd.; Distiller's grains: sorghum as the main raw material, the residue after solid-state fermentation, obtained after freeze-drying; casein and D-glucose: Xilong Technology Co., Ltd.

[0041] Agilent 1260 infinity liquid chromatography-mass spectrometry (Agilent, USA).

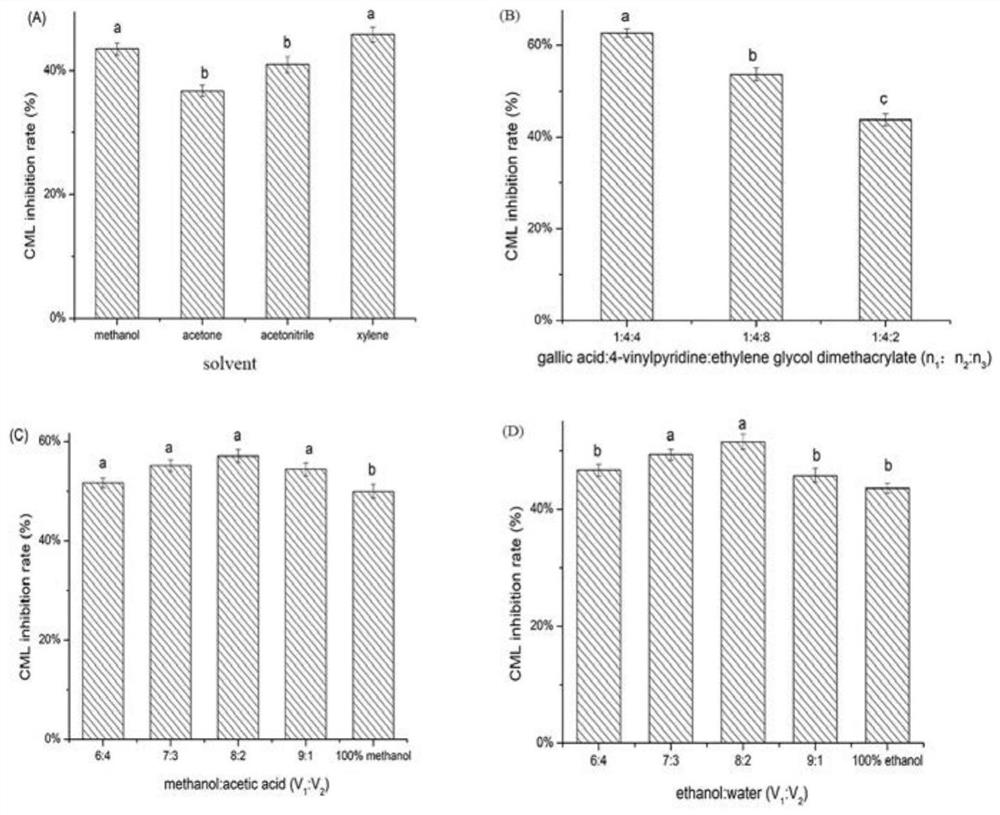

[0042] 2. Optimization of the preparation conditions of the filler

[0043] Taking the in...

Embodiment 2

[0057] Example 2 Preparation of distiller's grain extract

[0058] 1. Experimental materials and instruments

[0059] Distiller's grains: sorghum as the main raw material, the residue after solid-state fermentation, obtained after freeze-drying; casein and D-glucose: Xilong Technology Co., Ltd.; water (DDW): prepared using WaterPro water purification system (Labconco Corp.).

[0060] Agilent 1260 infinity liquid chromatography-mass spectrometry (Agilent, USA).

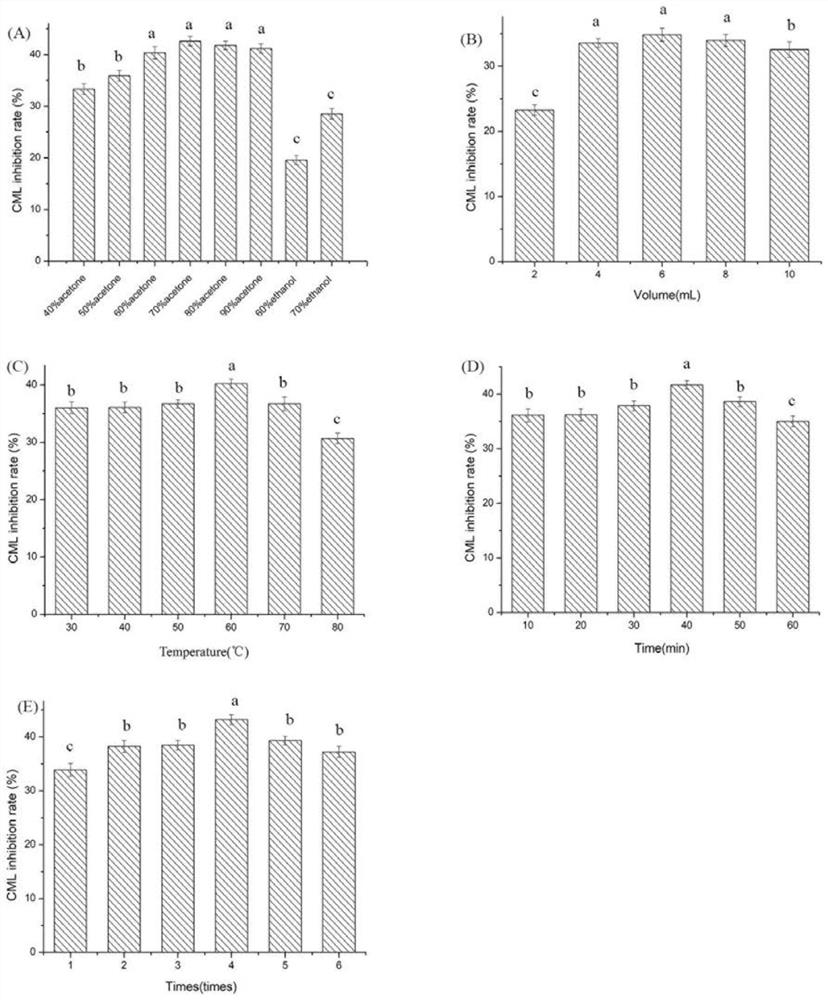

[0061] 2. Optimization of extraction conditions

[0062] Taking the inhibition rate of carboxymethyl lysine as an index, a single factor experiment method was adopted,

[0063] Weigh 0.2 g of distiller's grains and add 10 mL of ethanol-water mixture (volume ratios of ethanol:water are 6:4, 7:3, 8:2, 9:1, 100% ethanol) as solvent, heat and stir at 60°C After extraction for 30 min, after solid-liquid separation, the extract was collected; 1.5 mL distiller’s grains extract was loaded onto a solid-phase extraction colum...

Embodiment 3

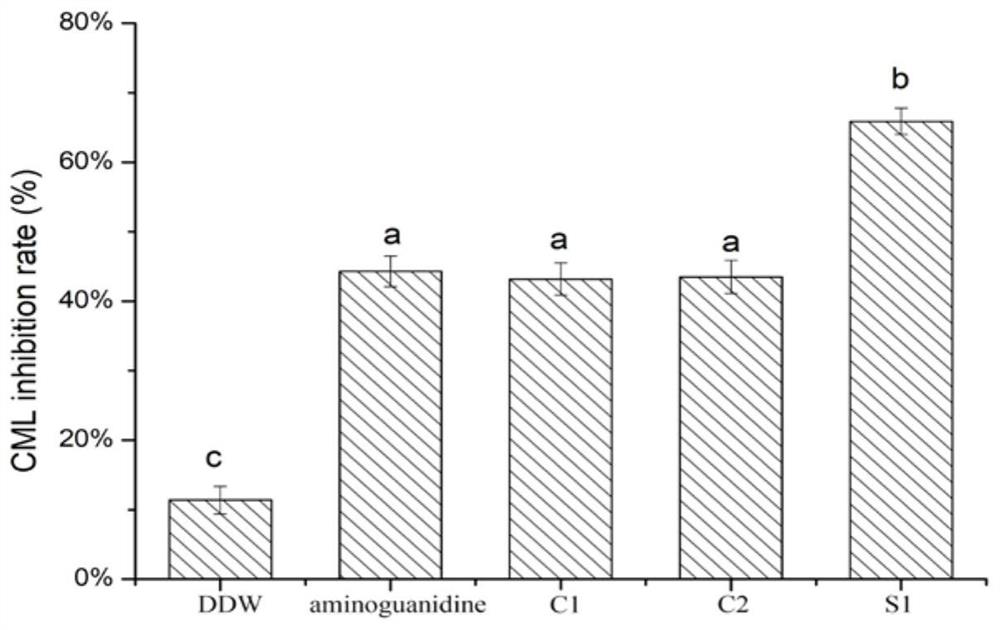

[0090] Example 3 Antioxidant properties of distiller's grains extract and inhibition rate to carboxymethyllysine

[0091] 1. Experimental materials and instruments

[0092] DPPH: Yuanye Biotechnology Co., Ltd.; FRAP kit: Beijing Banxia Technology Co., Ltd.; casein and D-glucose: Xilong Technology Co., Ltd.; disodium hydrogen phosphate dodecahydrate, sodium dihydrogen phosphate and aminoguanidine: J&K Science Ltd.; Agilent 1260 Infinity LC-MS (Agilent, USA).

[0093] 2. Experimental procedure

[0094] (1) Dissolve distiller's grain extracts C1, C2, and S1 in 5 mL of 70% acetone-water solvent respectively, and set aside.

[0095] (2) Scavenging ability for DPPH: Take 150 μL distiller’s grain extract and add to 2.85mL 6.6×10 -5 After mixing in mol / L DPPH solvent and reacting in the dark for 2 hours, measure the absorbance at 515nm. The inhibition rate of DPPH is:

[0096] Inhibition rate (%) = (1-A s / A c )×100%

[0097] Where As is the absorbance of the sample and Ac is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com