Composite emulsifier for animal feed, use method and application

A compound emulsifier and animal feed technology, which is applied in the field of compound emulsifiers, can solve the problems of unsatisfactory feed fat emulsification effect, and achieve the effects of solving insufficient bile acid secretion of animals, improving daily weight gain, and improving feed nutrient digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Polyglyceryl fatty acid ester 65%, sodium stearyl-2-lactate 15%, sodium saccharin 1.5%, sodium glutamate 1.5%, L-carnitine 1.5%, rice husk powder 0.5% and zeolite powder 15%. The above-mentioned components were weighed and placed in a small horizontal double-shaft paddle stainless steel mixer for 10 minutes to obtain a composite emulsifier.

[0049] To confirm the emulsifying power of the composite emulsifier in Example 1, add 0.1 g of the composite emulsifier to the oil-water mixture (soybean oil: water = 3: 7), homogenize and stir, and observe at room temperature and heat treatment respectively emulsifying power. Under the same conditions, a single emulsifier, sodium stearyl-2-lactate and polyglycerol fatty acid ester were added for homogenization and stirring as a control group.

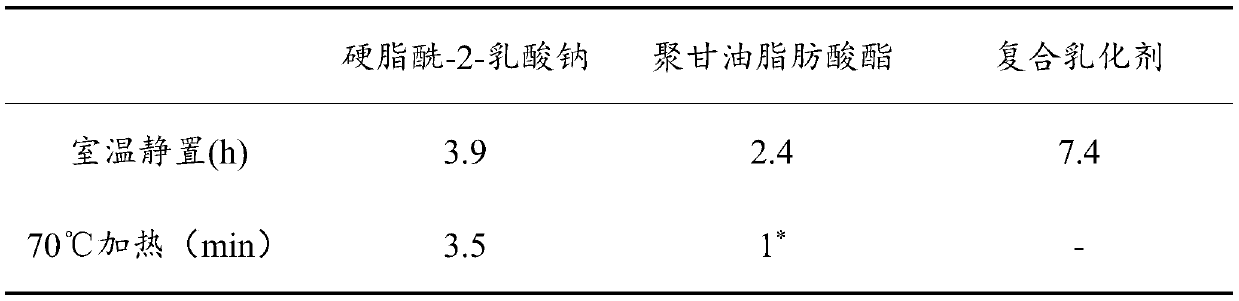

[0050] Table 1 The influence of emulsifiers on the emulsifying power (delamination time) of soybean oil emulsion

[0051]

[0052] Note:" * "Indicates demulsification; "-" indicates t...

Embodiment 2

[0065] Polyglyceryl fatty acid ester 70%, sodium stearyl-2-lactate 20%, sodium saccharin 2.5%, sodium glutamate 2.5%, L-carnitine 2.5%, rice husk powder 1.5% and zeolite powder 1%. The above-mentioned components were weighed and placed in a small horizontal double-shaft paddle stainless steel mixer for 10 minutes to obtain a composite emulsifier.

[0066] To confirm the emulsifying power of the composite emulsifier in Example 2, add 0.1 g of the composite emulsifier to the oil-water mixture (soybean oil: water = 3: 7), homogenize and stir, and observe at room temperature and heat treatment respectively emulsifying power. Under the same conditions, a single emulsifier, sodium stearyl-2-lactate and polyglycerol fatty acid ester were added for homogenization and stirring as a control group.

[0067] The impact of table 4 emulsifiers on the emulsifying power (delamination time) of soybean oil emulsion

[0068]

[0069] Note:" * "Indicates demulsification; "-" indicates that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com