Lithium ion battery, anode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electrolyte penetration and poor battery cycle performance improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

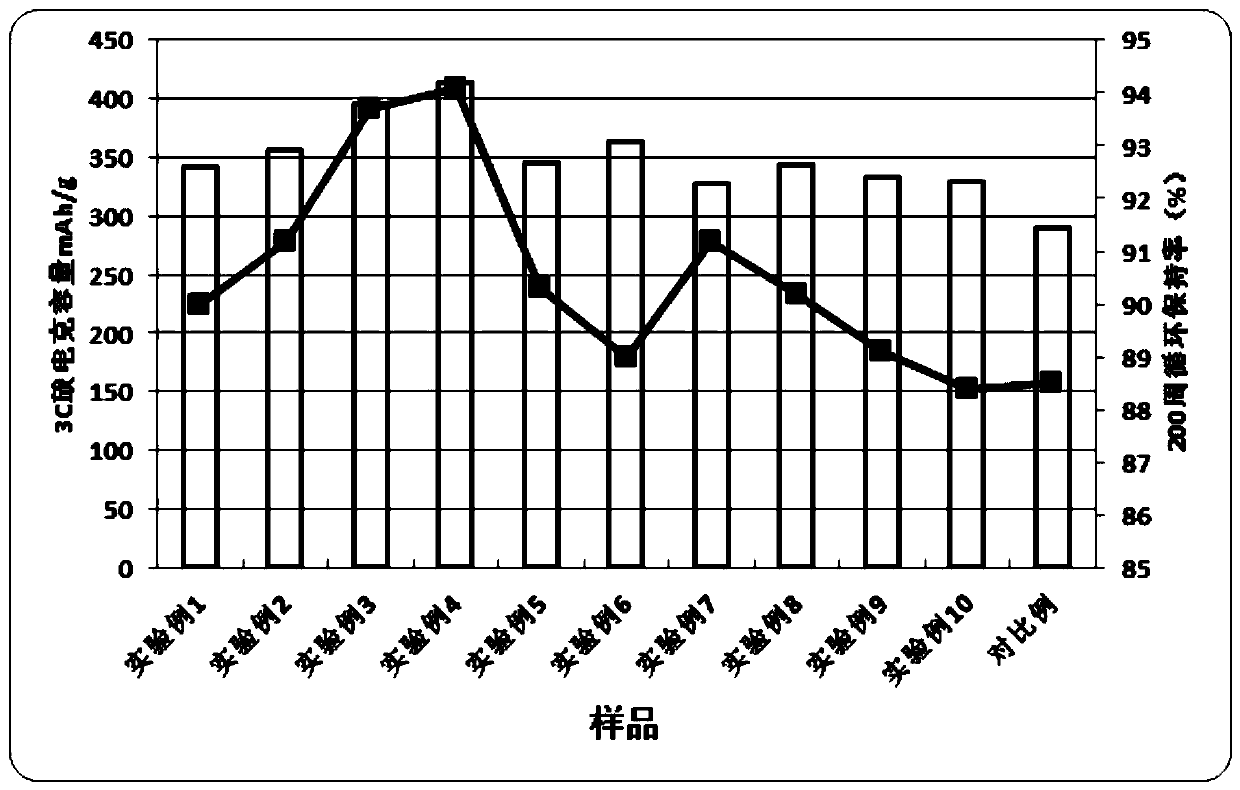

Examples

Embodiment 1

[0066] The present embodiment provides a kind of preparation method of lithium-ion battery negative electrode material, and it mainly comprises the following steps:

[0067] 1) Graphene oxide is synthesized by using graphite powder. The synthesis method of this step can be realized by using existing technologies, such as but not limited to using the Hummers method to synthesize graphene oxide in this embodiment by liquid phase oxidation. for example:

[0068] Put a certain amount of concentrated sulfuric acid in an ice-water bath for 4 hours, add a predetermined amount of graphite powder, slowly add potassium permanganate under vigorous stirring, keep the system temperature not exceeding 20°C, and put it into a 30-35°C container after stirring evenly. React in a water bath for 2-5 hours, then add deionized water so that the system temperature does not exceed 85-98°C, continue stirring for 15 minutes; add 1400mL deionized water and 150mL 30% (mass fraction) H 2 o 2 , filter i...

Embodiment 2

[0083] As an illustration of this embodiment, the inventor further found in the process of carrying out the present invention that the following steps can be further included after step 3) of embodiment 1 and before step 4):

[0084] 31) Soak the three-dimensional wrinkled graphene oxide powder PGO1 obtained in step 3) in an alkaline solution (that is, a weakly alkaline solution with certain corrosiveness, such as but not limited to: sodium oxide solution, potassium oxide solution, wherein the The concentration of the alkaline solution can be but not limited to 1~5mol / L), soak for a predetermined time, the soaking time is about 12-16h, such as soaking for 14h, so that the alkaline solution reacts with the oxygen-containing groups of graphene oxide (ie Weak corrosion reaction), in order to speed up its reaction speed, it can be stirred during soaking to make it uniformly dispersed, and the suspension formed by this graphene oxide powder PGO1 soaking solution is recorded as the t...

experiment example 1

[0093] Put 500mL of concentrated sulfuric acid in an ice-water bath for 4 hours, add 15g of graphite powder, slowly add 45g of potassium permanganate under vigorous stirring, keep the system temperature not exceeding 20°C, stir well and put it in a water bath of 30-35°C After reacting for 2-5 hours, add 700 mL of deionized water so that the temperature of the system does not exceed 85-98 ° C, and continue to stir for 15 minutes; respectively add 1400 mL of deionized water and 150 mL of 30% (mass fraction) H2O2, filter immediately, and fully wash with 1mol / L HCl From the filter cake to the filtrate, SO24- cannot be detected, and then washed with deionized water to become neutral. After freeze-drying, the obtained sample was denoted as graphene oxide PGO1.

[0094] A 0.25 g / L graphene oxide dispersion solution was prepared, and a spray drying experiment was carried out on a spray dryer. The obtained sample was designated as PGO1, and the obtained PGO1:C was mixed and dispersed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com