Silicon dioxide modified organosilicon defoaming agent and preparation method thereof

A technology of silicone defoamer and silicon dioxide, which is applied in the direction of foam dispersion/prevention, can solve the problems of limited defoaming ability of defoamers, achieve improved compatibility, simple preparation process, and facilitate large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

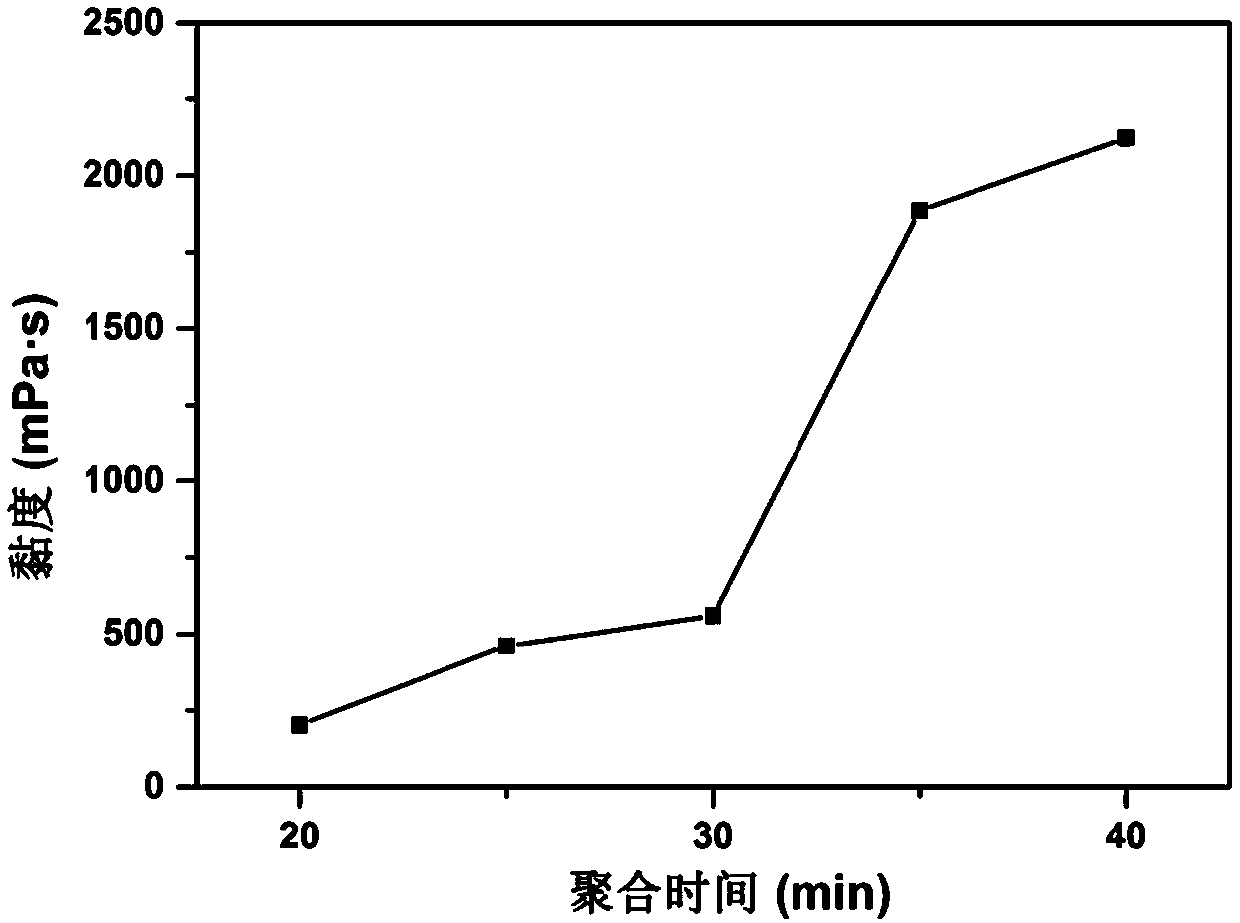

Embodiment 1

[0037] Add 100 g DMC and 0.02 g Me 4 NOH, under the condition of stirring, first raise the temperature to 90 ºC, and then gradually raise the temperature to 110 ºC, react for 30 min (calculate the time from heating to 90 ºC, and keep the final temperature at 110 ºC), add 5 g of modified nano-SiO 2 , after continuing to react for 50 min, add 2 g of hexamethyldisilazane for capping, heat up to 130 ºC to remove unreacted catalyst, distill under reduced pressure until no fraction comes out, and cool down at room temperature to obtain the silicone defoamer.

Embodiment 2

[0039] Add 100 g DMC and 0.02 g Me 4 NOH, under the condition of stirring, first raise the temperature to 90 ºC, then gradually raise the temperature to 110 ºC, react for 20 minutes (calculate the time from heating to 90 ºC, and keep the final temperature at 110 ºC), add 5 g of modified nano-SiO 2 , after continuing to react for 50 min, add 2 g of hexamethyldisilazane for end-capping, heat up to 130 ºC to remove unreacted catalyst, distill under reduced pressure until no fraction comes out, and obtain the silicone defoamer after cooling at room temperature .

Embodiment 3

[0041] Add 100 g DMC and 0.02 g Me 4NOH, under the condition of stirring, first raise the temperature to 90 ºC, then gradually raise the temperature to 110 ºC, react for 40 min (calculate the time from heating to 90 ºC, and keep the final temperature at 110 ºC), add 5 g of modified nano-SiO 2 , after continuing to react for 50 min, add 2 g of hexamethyldisilazane for end-capping, heat up to 130 ºC to remove unreacted catalyst, distill under reduced pressure until no fraction comes out, and obtain the silicone defoamer after cooling at room temperature .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com