Fresh kale slicing, enzyme-deactivation and green-maintaining processing equipment

A technology for cutting green and protecting kale, which is applied in metal processing, fruit and vegetable preservation, and heating preservation of fruits/vegetables. Grass smell, effect of preventing leaf browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

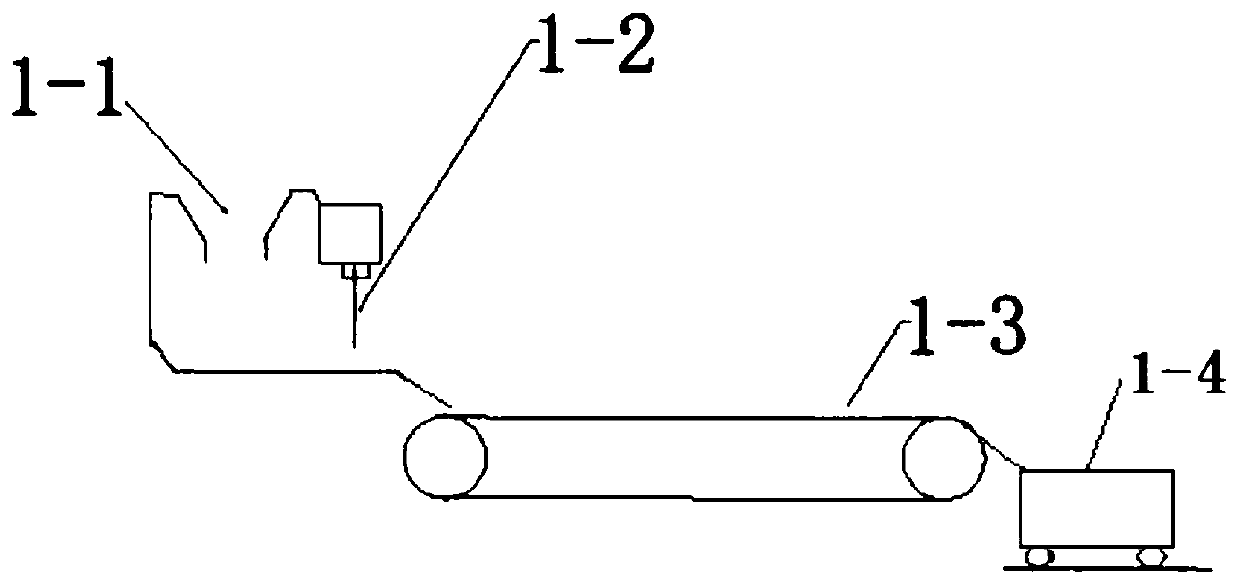

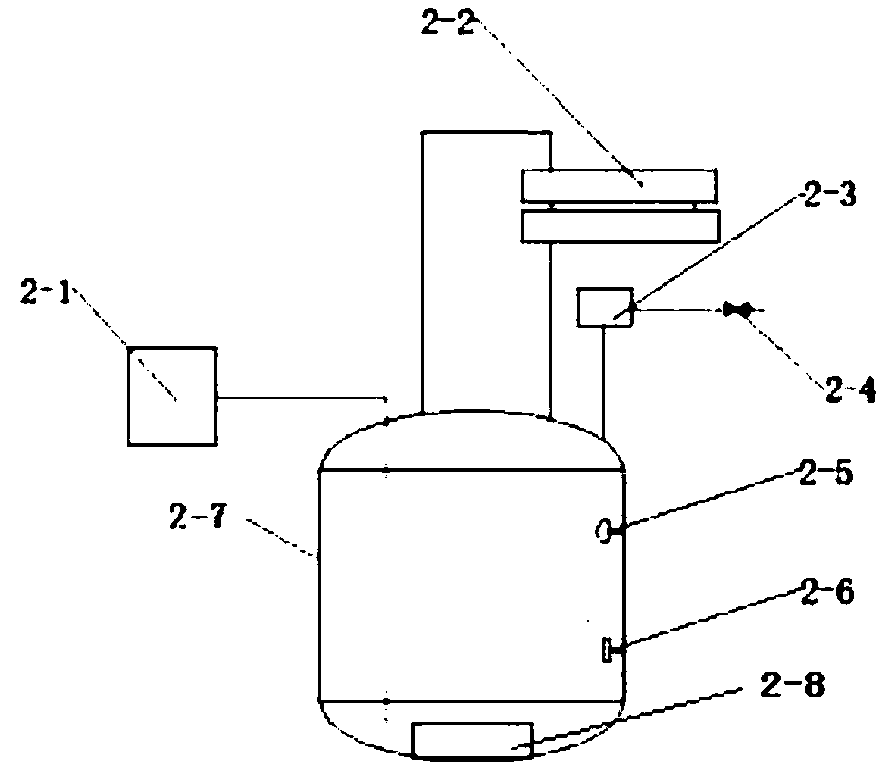

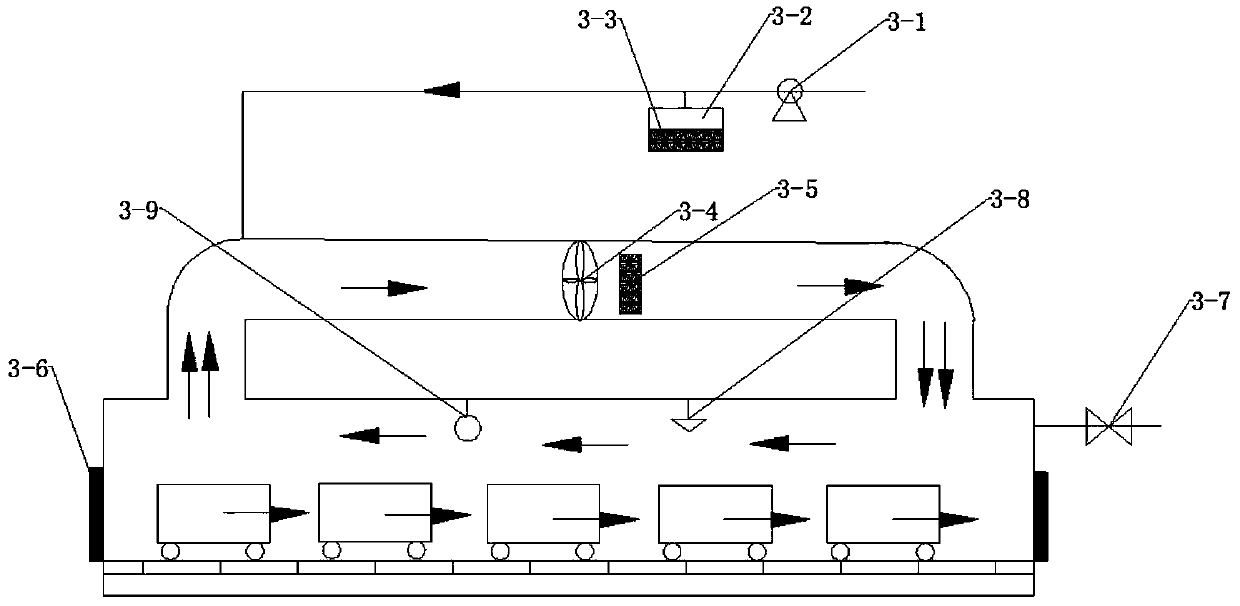

[0041] A processing equipment for fresh-cut greening and greening protection of kale, including a slicing device, a conveyor belt, an enzyme-linked ultrasonic decompression treatment device, a high-temperature and high-pressure saturated steam injection tunnel-type constant-temperature de-greening device, a low-temperature and high-pressure saturated steam injection tunnel-type constant-temperature cooling device, The process is as follows: After the kale is sliced by the slicing device, the kale slices are carried by the conveyor belt into the enzyme-linked ultrasonic decompression treatment device for grassy odor removal treatment, and then enter the high-temperature, high-pressure saturated steam injection tunnel-type constant temperature de-greening d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com