Novel processing method of printed circuit board

A technology for printed circuit boards and processing methods, which is applied to printed circuits connected to non-printed electrical components, printed circuit components, printed circuits assembled with electrical components, etc., and can solve solder joint drop-off, soldering failure, and poor heat dissipation and other problems, to achieve the effect of preventing sharp corner scratches, preventing collision damage, and ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

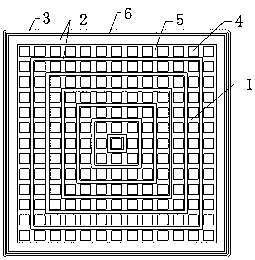

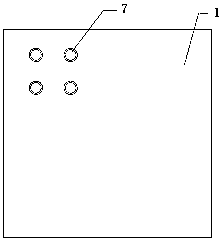

[0031] Such as Figures 1 to 4 A new processing method for printed circuit boards shown includes the following steps: Step 1, material cutting: take the raw materials and place them on the material cutting machine, and cut out the required copper-clad substrate 1 according to the size required by the production instruction sheet ;Step 2, Drilling: First use a pin machine to punch some pin holes on the short side of the copper-clad substrate, and then fix the combined board after the pin holes are punched on the workbench of the CNC drilling machine, and set the main shaft of the drilling machine Rotational speed and falling speed of the knife, drill holes on the above combination plate, after the combination plate is drilled, remove the combination plate from the workbench of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com