Preparation method of porous carbon-supported transition metal oxide composite material

A technology of porous carbon materials and transition metals, applied in the field of material chemistry, can solve problems such as high cost, complex process, and slow reaction rate, and achieve the effects of low cost, good material structure uniformity, and improved electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

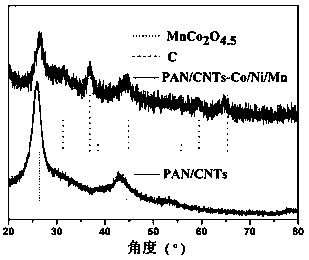

[0039] The preparation process of the element-free porous carbon material loaded transition metal oxide material is as follows:

[0040] Take the mass ratio CNT:PAN:PMMA=1:0.4:15; the solute mass fraction of the dimethylamide solution is 1%, and the average particle size of PMMA is 2-20μm.

[0041] (1) Dissolve PAN completely in dimethylamide; CNT is uniformly dispersed in absolute ethanol; then the two liquids are mixed, and PMMA is added in proportion, and the ultrasonic dispersion is uniform; the organic solvent is slowly evaporated under natural conditions; finally in N 2 Under the atmosphere, the temperature was raised to 400° C. for 2 hours at 3° C. / min, and then the temperature was raised to 800° C. for 4 hours to obtain a porous carbon material.

[0042] (2) Dissolve 1.74g of cobalt nitrate hexahydrate, 0.37g of ammonium fluoride, and 1.2g of urea in 80ml of deionized water, and form a pink solution under magnetic stirring;

[0043] (3) Add 1.422g of cetyltrimethylam...

Embodiment 2

[0049] Take the mass ratio CNT:PAN:PMMA=1:0.4:15; the solute mass fraction of the dimethylamide solution is 1%, and the average particle size of PMMA is 2-20μm.

[0050] (1) Dissolve PAN completely in dimethylamide; CNT is uniformly dispersed in absolute ethanol; then the two liquids are mixed, and PMMA is added in proportion, and the ultrasonic dispersion is uniform; the organic solvent is slowly evaporated under natural conditions; finally in N 2 Under the atmosphere, the temperature was raised to 400° C. for 2 hours at 3° C. / min, and then the temperature was raised to 800° C. for 4 hours to obtain a porous carbon material.

[0051] (2) Dissolve 1.74g of cobalt nitrate hexahydrate, 0.37g of ammonium fluoride, and 1.2g of urea in 80ml of deionized water, and form a pink solution under magnetic stirring;

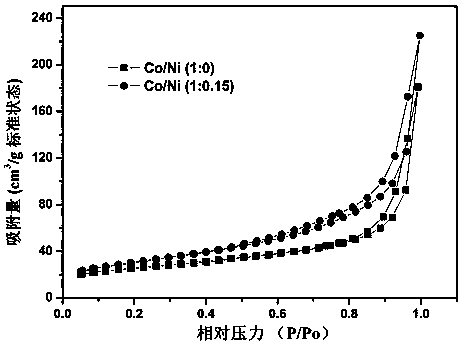

[0052] (3) Add cobalt nitrate hexahydrate and nickel nitrate hexahydrate into the pink solution in step (2) at a molar ratio of 1:0.05, stir magnetically to fully dissolve ...

Embodiment 3

[0058] Steps (1), (2), (4), (5), (6), (7) are the same as [Example 2],

[0059] Step (3): Add cobalt nitrate hexahydrate and nickel nitrate hexahydrate into the pink solution in step (2) at a molar ratio of 1:0.15, stir magnetically to make it fully dissolve, and the color of the solution turns dark pink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com