Nitrogen-sulfur double-doped non-metallic carbon-based oxygen reduction catalyst with grading holes and preparation

A double-doped, non-metallic technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low catalytic performance, poor stability, high cost and large-scale promotion of metal-air battery catalysts, and promote electron transfer. and mass transfer, good stability, and the effect of promoting the oxygen reduction reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

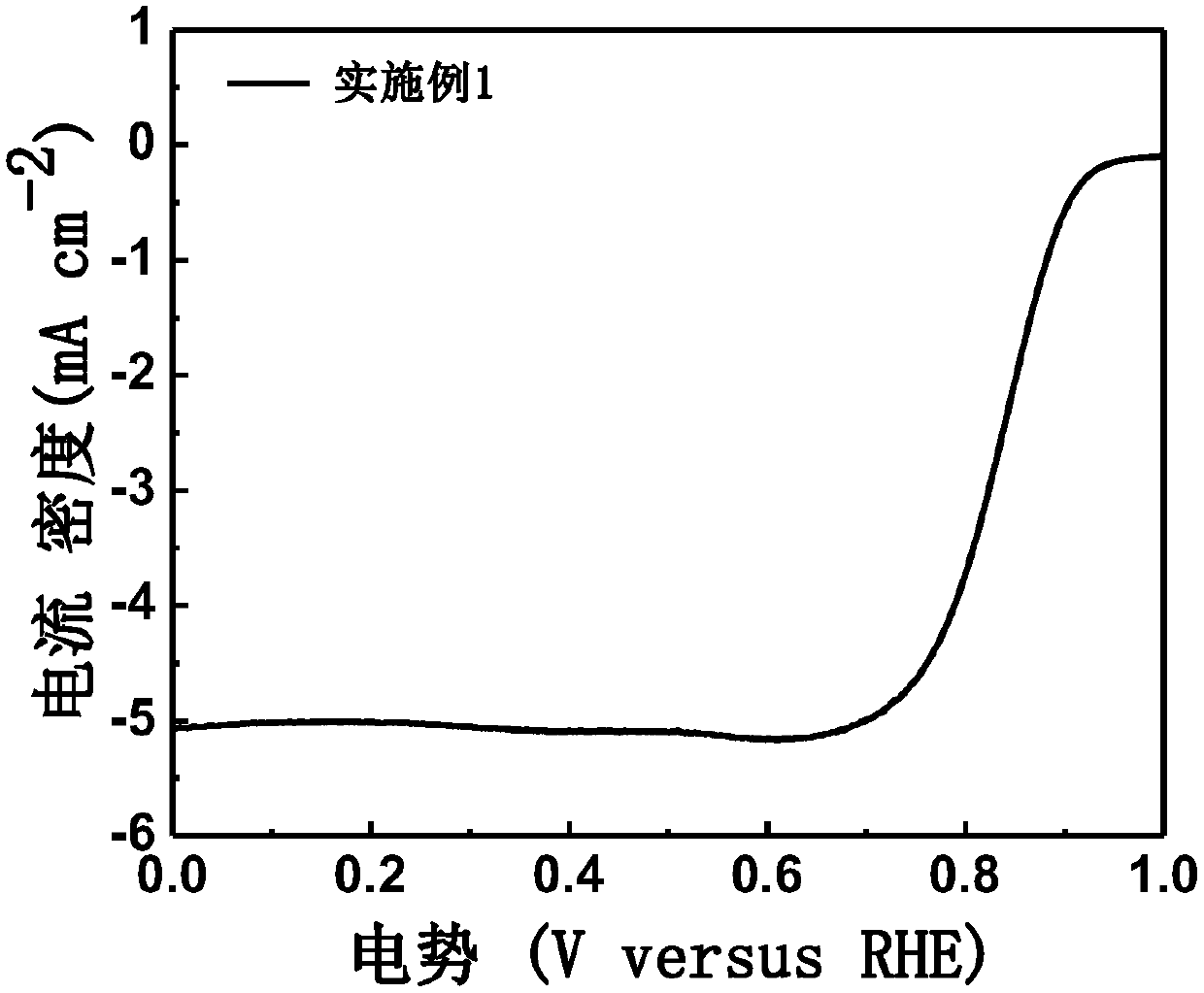

Embodiment 1

[0032] Step 1): Weigh 2.659g (15mmol) of thiocyanuric acid, 1.135g (1mmol) of β-cyclodextrin, and 0.5ml of concentrated sulfuric acid (96-97wt%) into 30ml of deionized water, sonicate for 30min until they are evenly mixed , and then transferred to a 100ml eggplant-shaped bottle, and heated up to 100°C while stirring. After the water solvent was completely evaporated, the temperature was raised to 160°C, and the reaction polymerization was carried out for 10 hours. The resulting product is taken out and ground to obtain an organic polymer material containing carbon, nitrogen and sulfur.

[0033] Step 2); put the organic polymer material into a porcelain boat and calcinate it in a high-temperature tube furnace with a gas flow rate of 100mlmin -1 Argon gas, first raise the temperature to 200°C at a heating rate of 5°C / min, hold for 1 hour, then raise the temperature to 350°C at a rate of 1°C / min, hold for 2 hours, then raise the temperature to 1000°C at a heating rate of 5°C / min,...

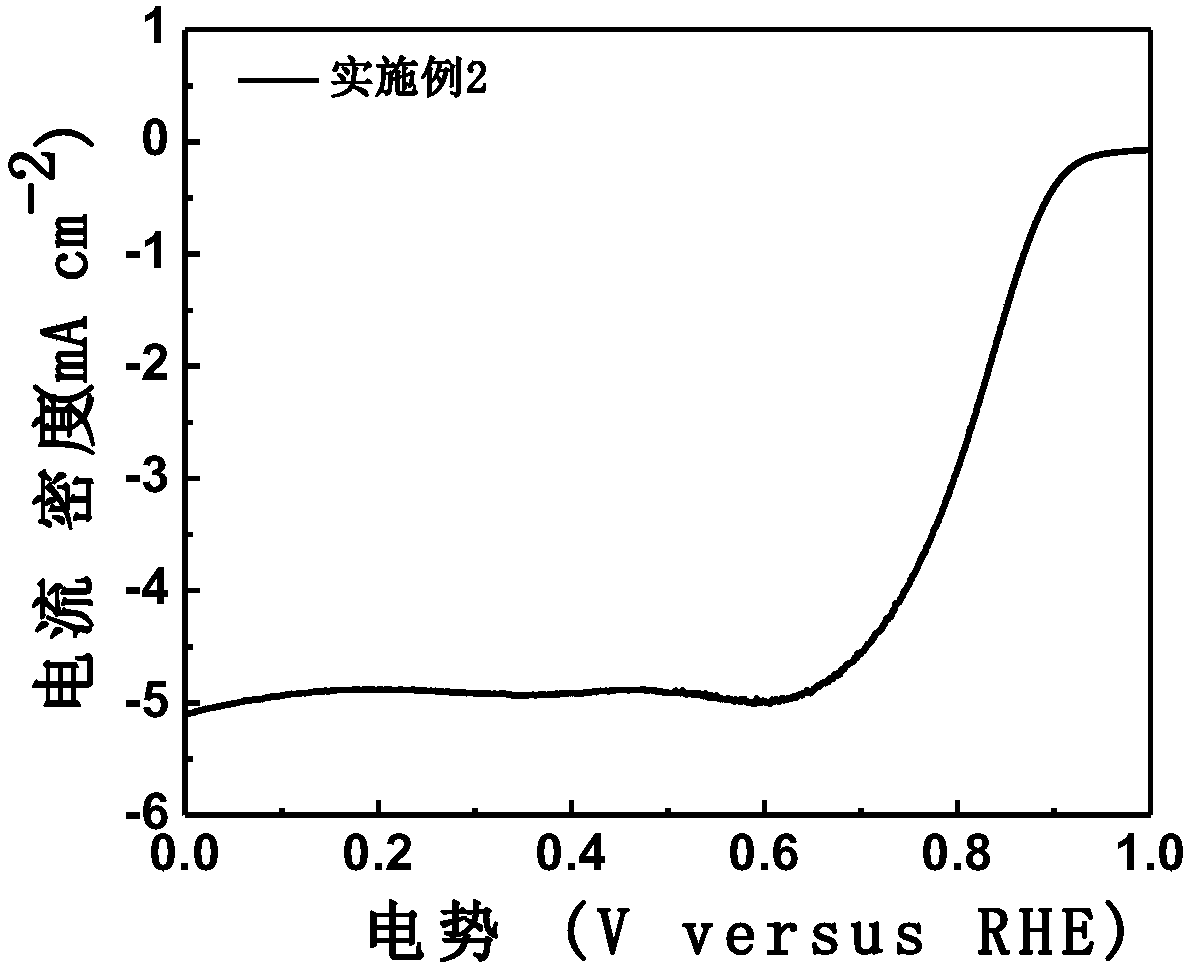

Embodiment 2

[0035] Step 1): Weigh 2.768g (15mmol) of chloronitrile, 2.614g (15mmol) of 1,3,5-benzenetrithiol, 1.135g (1mmol) of β-cyclodextrin, 0.5ml concentrated sulfuric acid (96- 97wt%) was added to 30ml of deionized water, ultrasonicated for 30min until uniformly mixed, then transferred to a 100ml eggplant-shaped bottle, and heated to 100°C while stirring, and after the water solvent was completely evaporated, the temperature was raised to 160°C, and the reaction polymerization was carried out for 8h. The resulting product is taken out and ground to obtain an organic polymer material containing carbon, nitrogen and sulfur.

[0036] Step 2): Put the organic polymer material into a porcelain boat and calcinate it in a high-temperature tube furnace with a gas flow rate of 100mlmin -1 Argon gas, first raise the temperature to 200°C at a heating rate of 5°C / min, hold for 1 hour, then raise the temperature to 350°C at a rate of 1°C / min, hold for 1 hour, then raise the temperature to 900°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com