A kind of iron-nitrogen doped oxygen reduction carbon catalyst with ordered hierarchical pores and preparation method thereof

A carbon catalyst and nitrogen-doped technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low catalytic performance, high cost, difficult large-scale promotion, and poor stability of catalysts. Achieve the effects of promoting electron transfer and mass transfer, efficient oxygen reduction reaction catalytic performance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

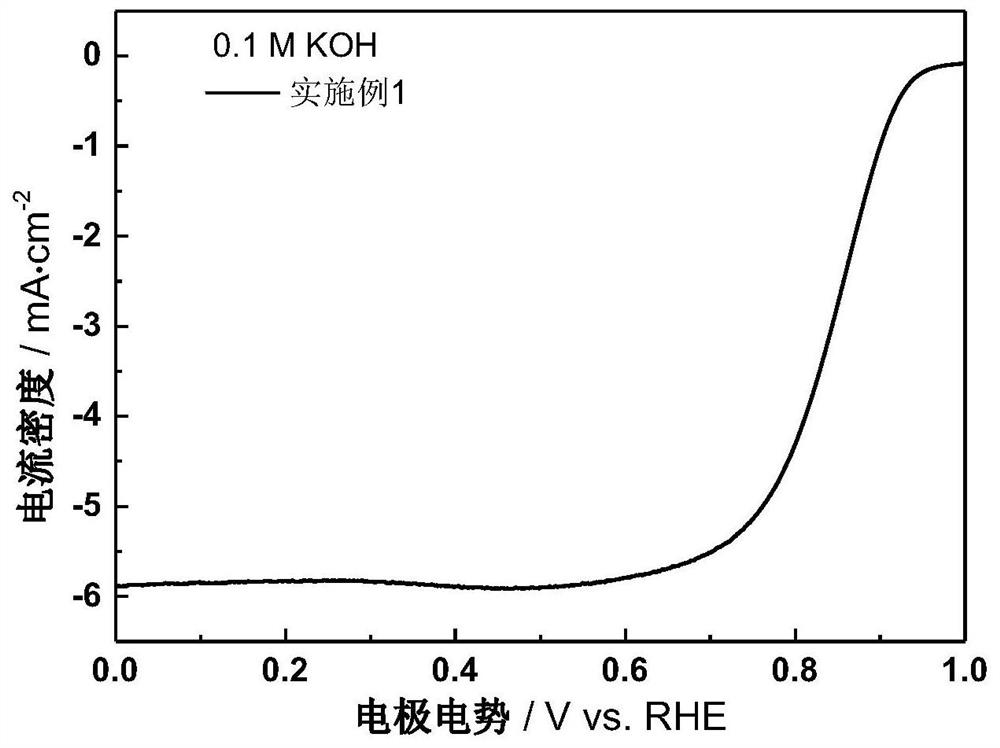

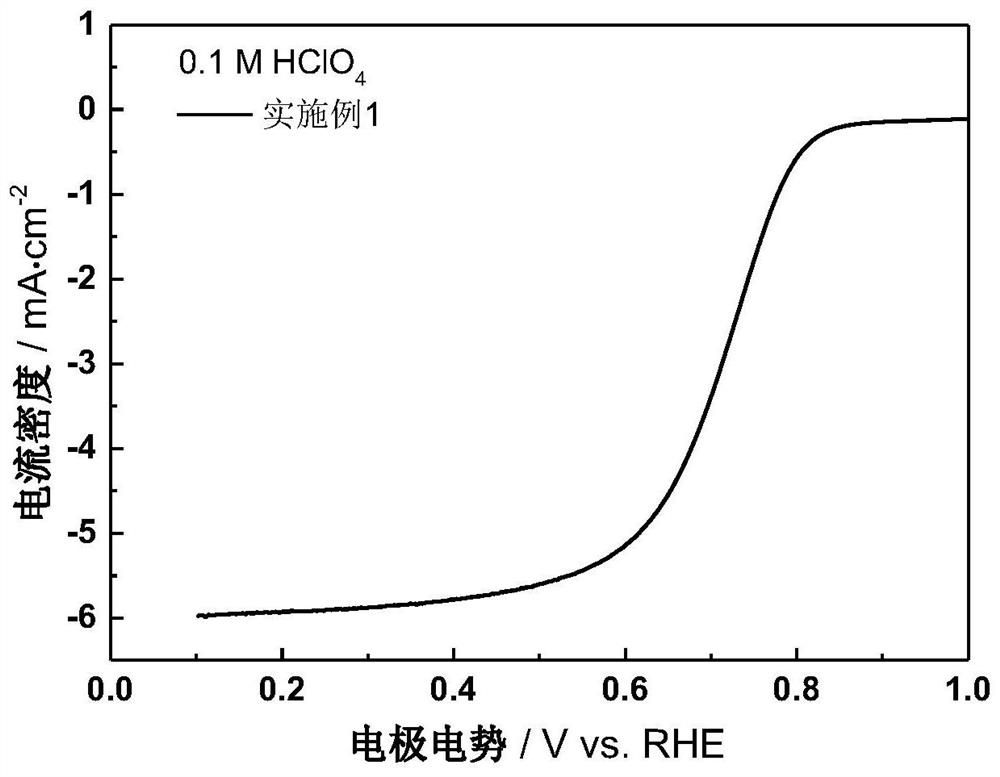

Embodiment 1

[0033] Step 1): In a three-necked flask, add 80ml of water and heat to 75°C, then add 7.0g of styrene under vigorous stirring, and in another 10ml centrifuge tube, mix 0.024g of NaOH and 0.024g of NaOH 2 CO 3 Soluble in 5mL water and contain 0.03gK 2 S 2 o 8 Add 5ml of aqueous solution to the previous solution, pass nitrogen gas under the liquid surface for 10 minutes, and keep the temperature at 75°C for 12 hours to synthesize 300nm monodisperse polystyrene spheres. After the reaction is completed, return to room temperature and perform suction filtration to form a filter cake .

[0034] Step 2): 8.15g (0.0274mol) of Zn(NO 3 ) 2 ·6H 2 O, 6.75g (0.0822mol) of 2-methylimidazole and 0.045g (0.000274mol) FeCl 3 ·6H 2O was dissolved in 45ml of methanol solution. Then a piece of monolithic PS template was immersed in the above solution for 1 h, and further treated with vacuum degassing for 10 min, so that all the interstitial spaces between the 3D colloidal spheres were fi...

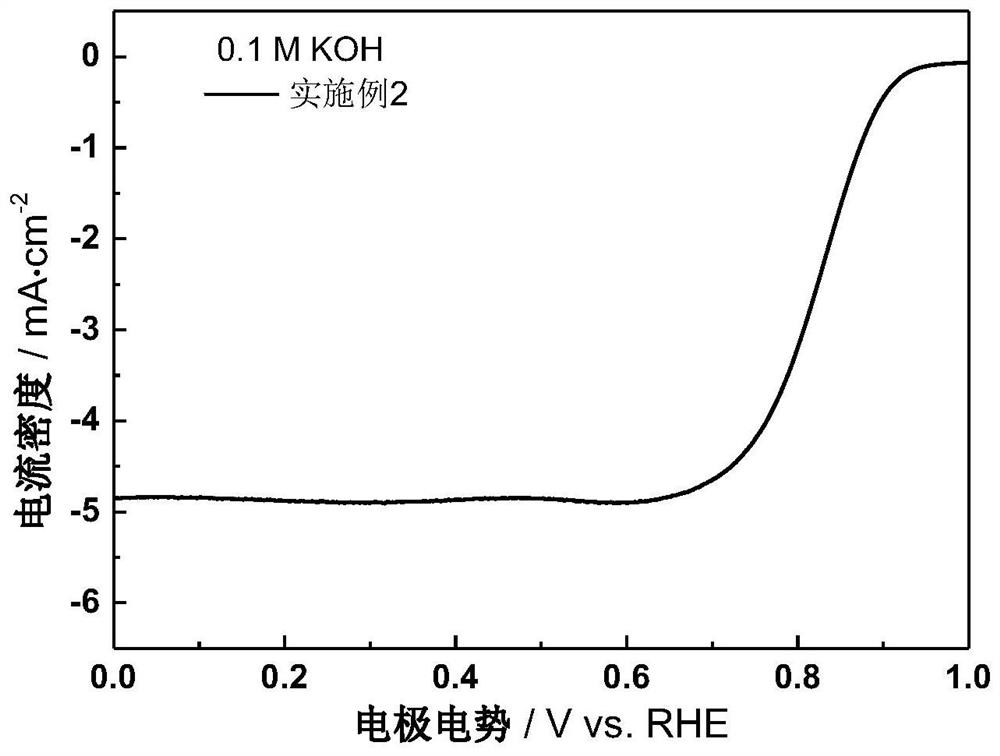

Embodiment 2

[0036] Step 1): In a three-necked flask, add 80ml of water and heat to 75°C, then add 7.0g of styrene under vigorous stirring, and in another 10ml centrifuge tube, mix 0.024g of NaOH and 0.024g of NaOH 2 CO 3 Soluble in 5mL water and contain 0.03gK 2 S 2 o 8 Add 5ml of aqueous solution to the previous solution, pass nitrogen gas under the liquid surface for 10 minutes, and keep the temperature at 75°C for 12 hours to synthesize 300nm monodisperse polystyrene spheres. After the reaction is completed, return to room temperature and perform suction filtration to form a filter cake .

[0037] Step 2): 8.15g (0.0274mol) of Zn(NO 3 ) 2 ·6H 2 O, 6.75g (0.0822mol) of 2-methylimidazole and 0.067g (0.000411mol) of FeCl 3 ·6H 2 O was dissolved in 45 mL of methanol solution. Then a piece of monolithic PS template was immersed in the above solution for 1 h, and further treated with vacuum degassing for 10 min, so that all the interstitial spaces between the 3D colloidal spheres we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com