Preparation method of inorganic perovskite-coated MXene two-dimensional layered anode material

A two-dimensional layered, negative electrode material technology, used in battery electrodes, secondary batteries, electrical components, etc., can solve the problems of structural instability, mechanical orientation, affecting processing and stability, and achieve excellent physical and chemical properties, cost Inexpensive and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of an inorganic perovskite-coated MXene two-dimensional layered negative electrode material, comprising the following steps:

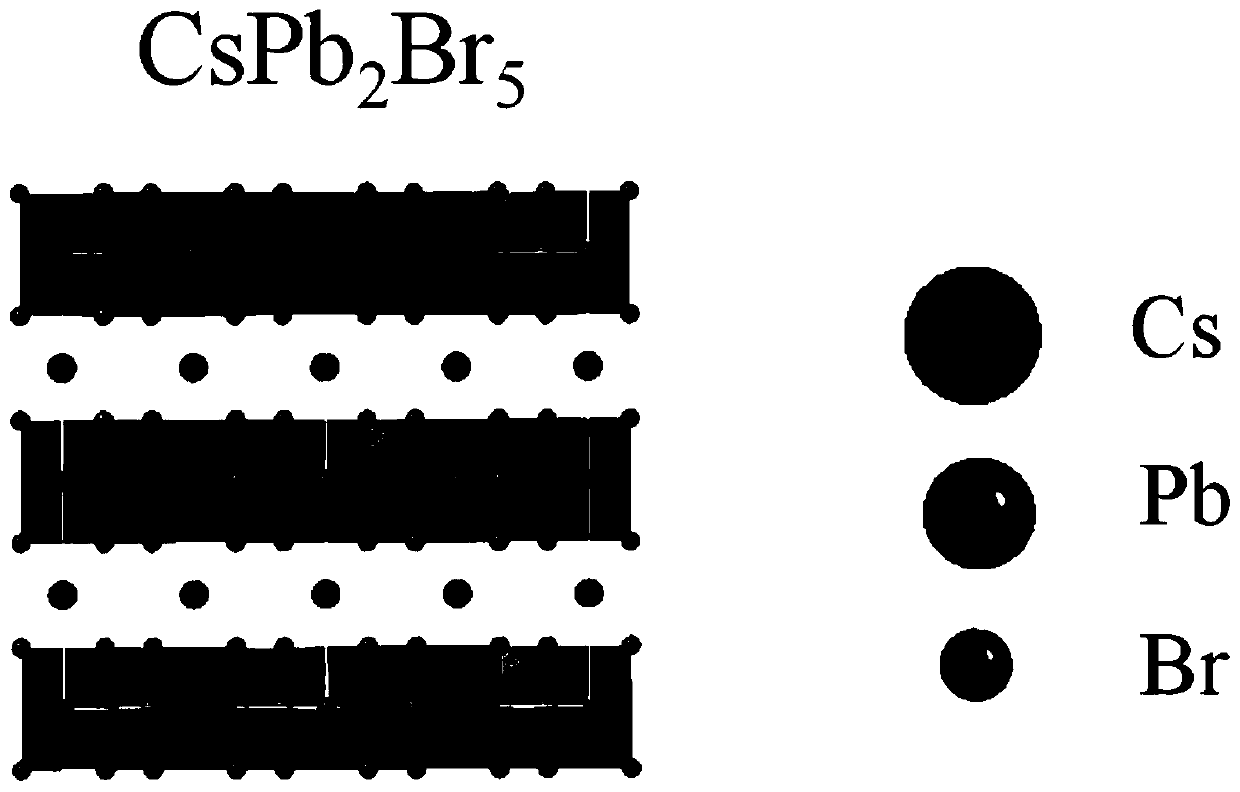

[0025] S1. Add 2 mol of lead bromide and 1 mol of cesium bromide to 1L of N,N-dimethylformamide at the same time, heat to 68°C, and stir for 2.5 hours to obtain an inorganic perovskite material precursor. Nitrogen gas is introduced during the stirring process;

[0026] S2, the Ti 3 AlC 2 The powder was mixed with 35% HF aqueous solution at a molar ratio of 1:2, stirred and reacted, washed by centrifugation, and vacuum-dried at 78°C for 11 hours to obtain Ti 3 C 2 powder;

[0027] S3, weigh 1mol of Ti 3 C 2 Add the powder to the inorganic perovskite material precursor, continue heating to 68°C, stir for 2.5 hours, and pass nitrogen gas during the stirring process to obtain the precursor solution;

[0028] S4. Add toluene to the precursor solution, centrifuge three times, and vacuum-dry the solid obtained at 68° C. for 1...

Embodiment 2

[0030] A preparation method of an inorganic perovskite-coated MXene two-dimensional layered negative electrode material, comprising the following steps:

[0031] S1. Put 2 mol of lead bromide in a three-necked beaker, then add 1L of N,N-dimethylformamide, heat to 70°C, stir to fully dissolve, then add 1 mol of cesium bromide to continue the reaction, the whole reaction process Continue for 3 hours to obtain the precursor of inorganic perovskite materials. During the stirring and reaction process, the mixed gas of nitrogen and argon is continuously introduced to avoid the influence of humidity in the air;

[0032] S2, the Ti 3 AlC 2 The powder was mixed with 45% HF aqueous solution at a molar ratio of 1:2, stirred and reacted, washed by centrifugation, and vacuum-dried at 82°C for 13 hours to obtain Ti 3 C 2 powder;

[0033] S3, weigh 1mol of Ti 3 C 2 Add the powder into the inorganic perovskite material precursor, continue heating to 70°C, stir for 3 hours, and pass nitr...

Embodiment 3

[0036] A preparation method of an inorganic perovskite-coated MXene two-dimensional layered negative electrode material, comprising the following steps:

[0037] S1. Put 1mol of cesium bromide in a three-necked beaker, then add 1L of N,N-dimethylformamide, heat to 70°C, stir to make it fully dissolved, then add 2mol of lead bromide to continue the reaction, the whole reaction process Continue for 3 hours to obtain the precursor of inorganic perovskite materials. During the stirring and reaction process, the mixed gas of neon and argon is continuously introduced to avoid the influence of humidity in the air;

[0038] S2, the Ti 3 AlC 2 The powder was mixed with 40% HF aqueous solution at a molar ratio of 1:2, stirred and reacted, washed by centrifugation, and vacuum-dried at 80°C for 12 hours to obtain Ti 3 C 2 powder;

[0039] S3, weigh 1mol of Ti 3 C 2 Add the powder to the inorganic perovskite material precursor, continue heating to 70°C, stir for 2.5 hours, and pass n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com