Making method for olaquindox molecularly imprinted membrane electrochemical sensor

A molecularly imprinted membrane, electrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of high detection environment requirements, unstable enzymes and antibodies, time-consuming sample pretreatment, etc., to overcome the processing process The effect of cumbersome, low detection limit, convenient adsorption and elution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of polydopamine@graphene composite

[0043]Dopamine hydrochloride was made into 1 mg / mL with Tris-HCl buffer solution (pH=8.5), and then the graphene powder was dispersed into 1 mg / mL with the above-mentioned solution, protected from light, stirred by magnetic force for 5 h, and then washed with double distilled water , filtered several times, dried in a vacuum oven, and set aside.

[0044] (2) Electrode pretreatment

[0045] The surface of the glassy carbon electrode was polished with 1.0 μm, 0.3 μm, and 0.05 μm alumina powder in sequence, and after being completely rinsed with double distilled water, the 3 1mmol / L K 3 [Fe(CN) 6 ] The solution was scanned by cyclic voltammetry in the range of -0.2 to 0.6V for multiple cycles until a stable electrochemical response was obtained, and then dried in air for later use.

[0046] (3) Drop-coating polydopamine@graphene composite

[0047] Prepare the synthesized polydopamine@graphene polymer with N, N-dimet...

Embodiment 2

[0055] (1) Preparation of polydopamine@graphene composite

[0056] Dopamine hydrochloride was made into 1 mg / mL with Tris-HCl buffer solution (pH=8.5), and then the graphene powder was dispersed into 1 mg / mL with the above-mentioned solution, protected from light, stirred by magnetic force for 5 h, and then washed with double distilled water , filtered several times, dried in a vacuum oven, and set aside.

[0057] (2) Electrode pretreatment

[0058] The surface of the glassy carbon electrode was polished with 1.0 μm, 0.3 μm, and 0.05 μm alumina powder in sequence, and after being completely rinsed with double distilled water, the 3 1mmol / L K 3 [Fe(CN) 6 ] The solution was scanned by cyclic voltammetry in the range of -0.2 to 0.6V for multiple cycles until a stable electrochemical response was obtained, and then dried in air for later use.

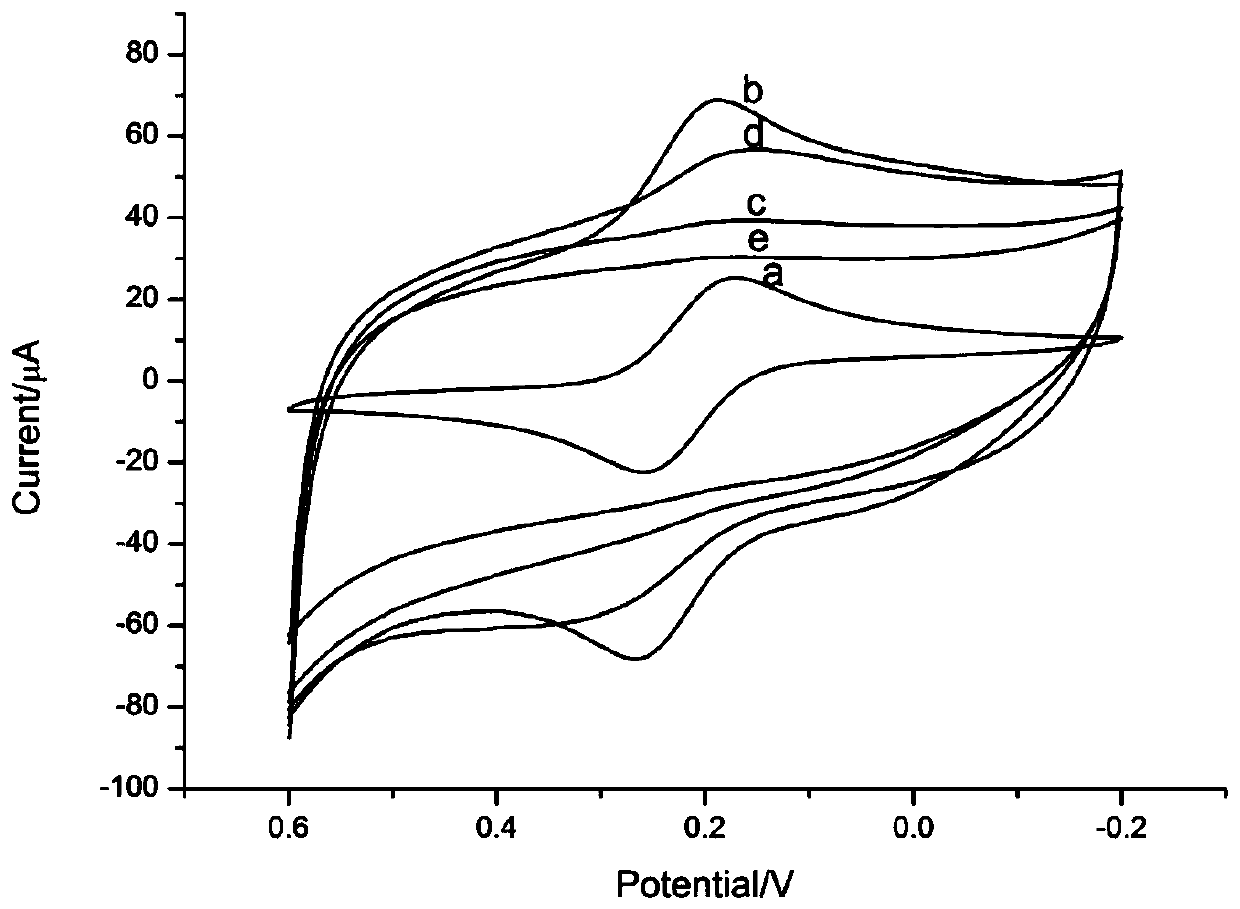

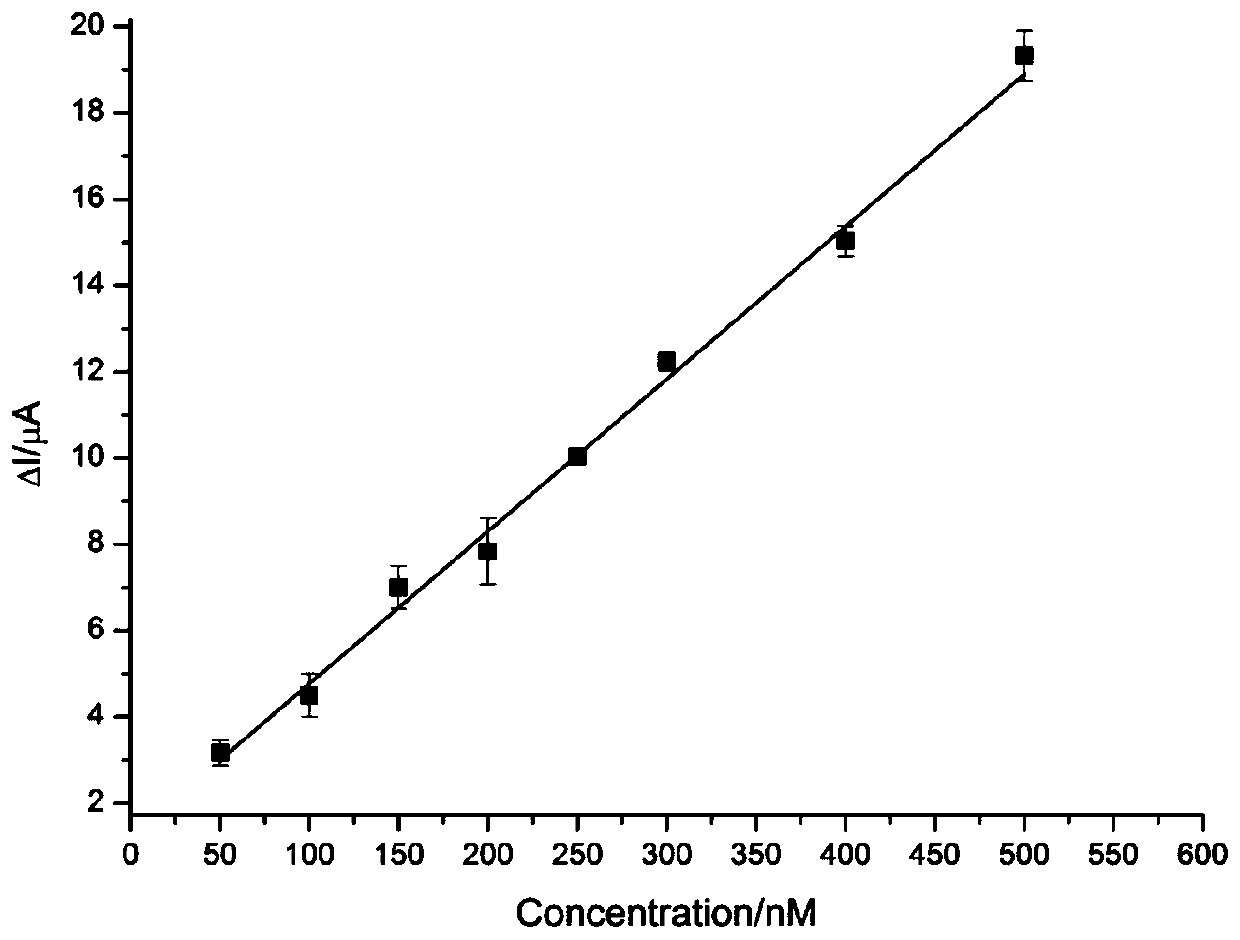

[0059] like figure 1 As shown, cyclic voltammetry is an effective method to monitor the electron transfer process on the modified ele...

Embodiment 3

[0069] (1) Preparation of polydopamine@graphene composite

[0070] Dopamine hydrochloride was made into 1 mg / mL with Tris-HCl buffer solution (pH=8.5), and then the graphene powder was dispersed into 1 mg / mL with the above-mentioned solution, protected from light, stirred by magnetic force for 5 h, and then washed with double distilled water , filtered several times, dried in a vacuum oven, and set aside.

[0071] (2) Electrode pretreatment

[0072] The surface of the glassy carbon electrode was polished with 1.0 μm, 0.3 μm, and 0.05 μm alumina powder in sequence, and after being completely rinsed with double distilled water, the 3 1mmol / L K 3 [Fe(CN) 6 ] The solution was scanned by cyclic voltammetry in the range of -0.2 to 0.6V for multiple cycles until a stable electrochemical response was obtained, and then dried in air for later use.

[0073] (3) Drop-coating polydopamine@graphene composite

[0074] Prepare the synthesized polydopamine@graphene polymer with N, N-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com