Novel automobile light guide fixing structure

A fixed structure and light guide technology, which is applied in the field of automotive lighting, can solve problems such as uneven lighting and space position restrictions, and achieve uniform lighting and uniform lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to fully understand the technical solutions and beneficial effects of the present invention, a further detailed description will be given below in conjunction with specific embodiments and accompanying drawings.

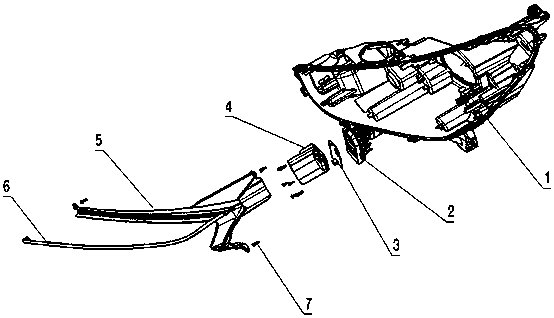

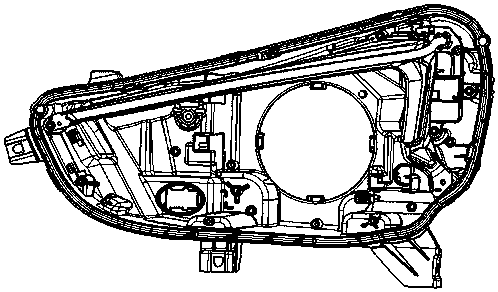

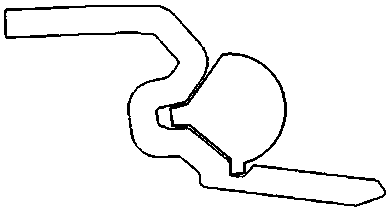

[0016] Such as Figure 1-2 A novel light guide fixing structure shown includes a lamp housing 1 , a radiator 2 , a PCB board 3 , a light guide bracket 4 , a light guide support 5 , a light guide 6 and several screws 7 . The lamp housing 1 is used as the assembly body, and other components are directly or indirectly fixed on the lamp housing. Specifically, the PCB board 3 and the light guide bracket 4 are fixed to the heat sink 2 by two 3X8 screws to form a subassembly, the subassembly is fixed to the lamp housing 1 by three 4X14 screws, and the light guide support 5 is fixed by three 4X14 screws. Screws are also fixed to the lamp housing 1 . The light guide with a slender shape is fixed as follows: First, the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com