Height online monitoring device and closed-loop control method for laser cladding additive forming

A technology of additive forming and laser cladding, applied in the field of laser cladding and laser additive manufacturing, laser cladding additive forming height online monitoring device and closed-loop control, which can solve the problem of inappropriate lifting height of cladding nozzle and cladding. The problem of different heights can solve the problem of inappropriate lifting height of the cladding nozzle and inconsistent cladding height, ensuring consistency and fast calculation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

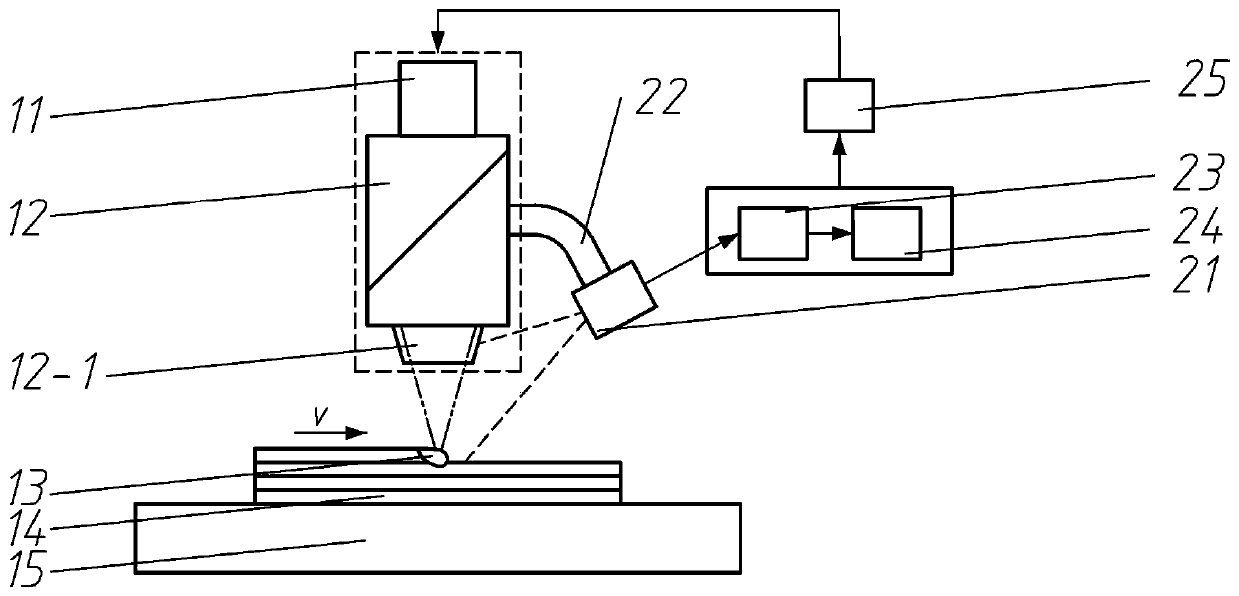

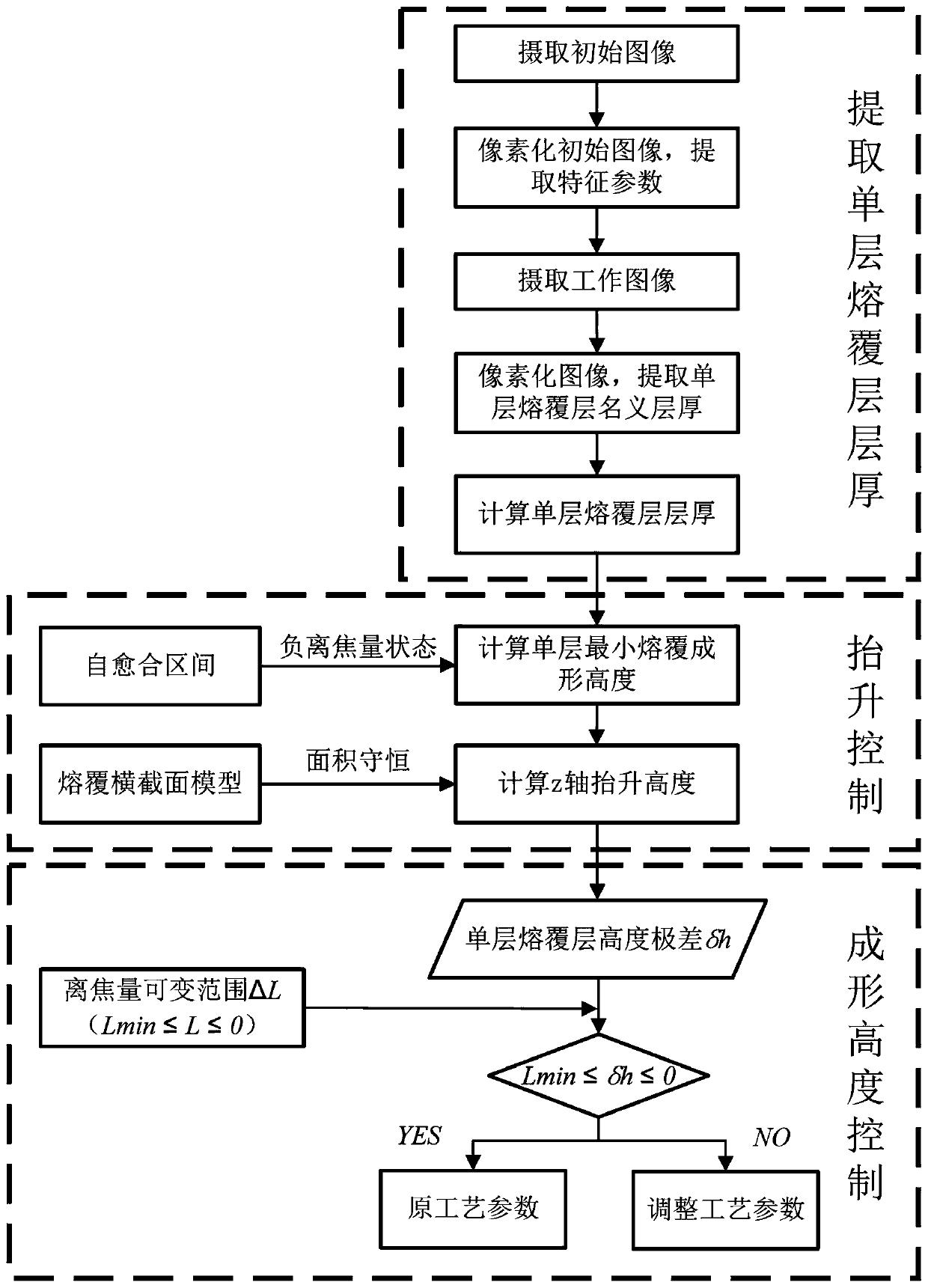

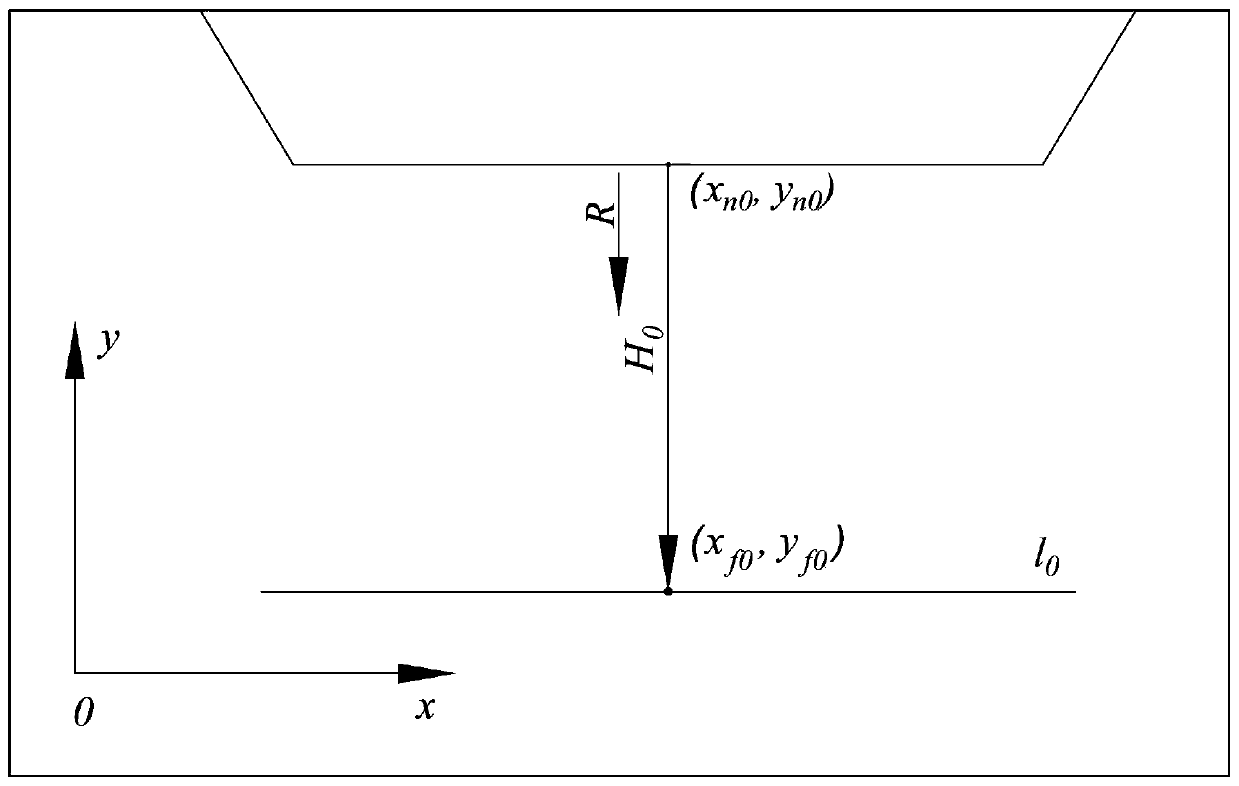

[0045] See figure 1 , figure 1 It is a schematic diagram of the laser cladding additive forming height online monitoring device of the present invention. The laser cladding additive forming cladding nozzle forming height online monitoring device is used in the laser rapid manufacturing process, including a cladding forming unit and a monitoring control unit. The cladding forming unit includes a laser 11 , a cladding head 12 , a molten pool 13 , a formed cladding layer 14 and a substrate 15 . The laser 11 is used to generate a laser beam to be injected into the laser processing area above the substrate 15 through a series of processes of collimation, beam expansion and focusing. The cladding head 12 is integrated in a motion processing center (a dotted box in the figure), and can move in three directions of x, y, and z, including the cladding spray head 12-1. The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com