Galvanized tightly adhered stainless steel band and stainless steel binding band made of same

A stainless steel strip and stainless steel technology, applied in the field of stainless steel, can solve the problems of reduced surface flatness of stainless steel strapping, increased difficulty of electroplating control, peeling off of zinc coating, etc., so as to achieve less blistering or peeling, less transcrystalline brittle cracking, and adhesion small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

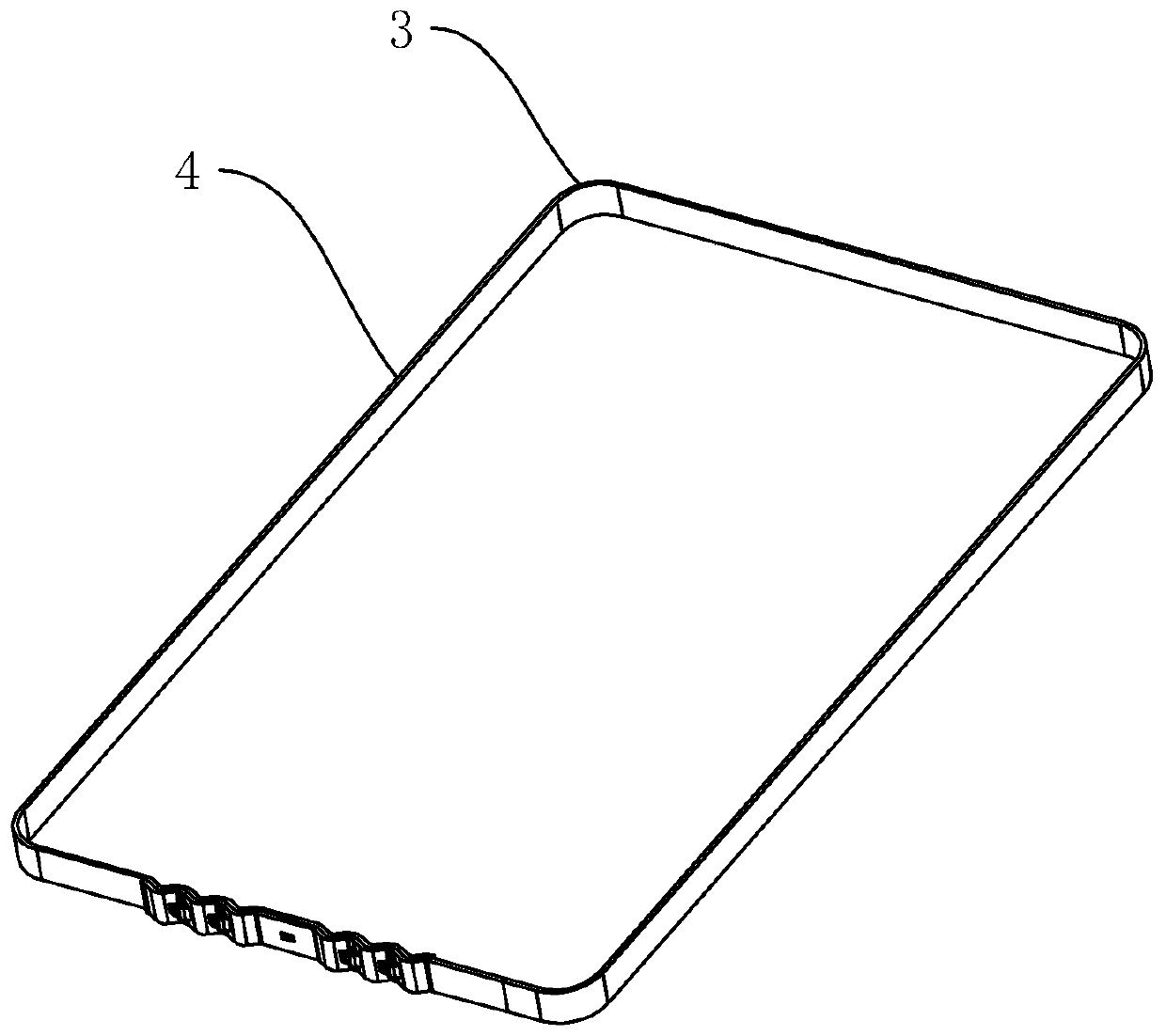

Image

Examples

Embodiment 1

[0049] A galvanized tightly adhered stainless steel strip, the production steps are as follows:

[0050] S1: In the converter with molten iron and scrap steel, carry out conventional top-bottom combined blowing to control the blowing oxygen pressure to 0.85-0.88MPa. When the tapping temperature is 1645-1650°C, detect the carbon content in the molten steel, and control the carbon at the end of the converter to be 0.05-0.08wt%, and then tap steel into the ladle;

[0051] S2: Argon is blown from the converter to the ladle during the whole process. When the molten steel in the ladle reaches 1 / 4 of the maximum capacity of the molten steel in the ladle, add aluminum carbide whiskers, aluminum ingots, silicon-manganese alloys, and high-carbon ferrochrome to the ladle. , vanadium-iron alloy powder, nickel-iron alloy, cobalt alloy, etc., the mass ratio of aluminum ingots and aluminum carbide whiskers is 1.25-1.28:1, and the above-mentioned additions are completed before the molten stee...

Embodiment 2

[0080] A stainless steel binding strap and a galvanized closely adhered stainless steel strip, based on the basis of Example 1B, the difference is that the mass ratio of metal aluminum and aluminum carbide whiskers added is 1.2:1, and the molten steel of S2 is kept The content of other elemental components except C is close to that of Example 1B.

Embodiment 3

[0082] A stainless steel binding strap and a galvanized closely adhered stainless steel strip, based on the basis of Example 1B, the difference is that the mass ratio of metal aluminum and aluminum carbide whiskers added is 1.3:1, and the molten steel of S2 is kept The content of other elemental components except C is close to that of Example 1B.

[0083] The stainless steel strip is obtained according to the above production method, and the composition of the obtained stainless steel strip is as follows.

[0084]

[0085]

[0086] The stainless steel strips obtained in Comparative Example 1 to Comparative Example 6, Embodiment 2 and Embodiment 3 were tested, and the test results are as follows.

[0087]

Comparative example one

Comparative example two

Comparative example three

Comparative example four

Comparative example five

Comparative example six

Embodiment two

Embodiment three

C / wt%

0.52

0.08

0.39

0.52

0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com