Stepped rotary shearing device for gas hydration separation

A hydration separation and rotational shearing technology, which is applied in the petroleum industry, chemical/physical/physical-chemical stationary reactors, and liquid carbon-containing fuels, etc., can solve problems such as the increase of experimental temperature, increase gas content, and improve transfer efficiency. , the effect of improving the transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

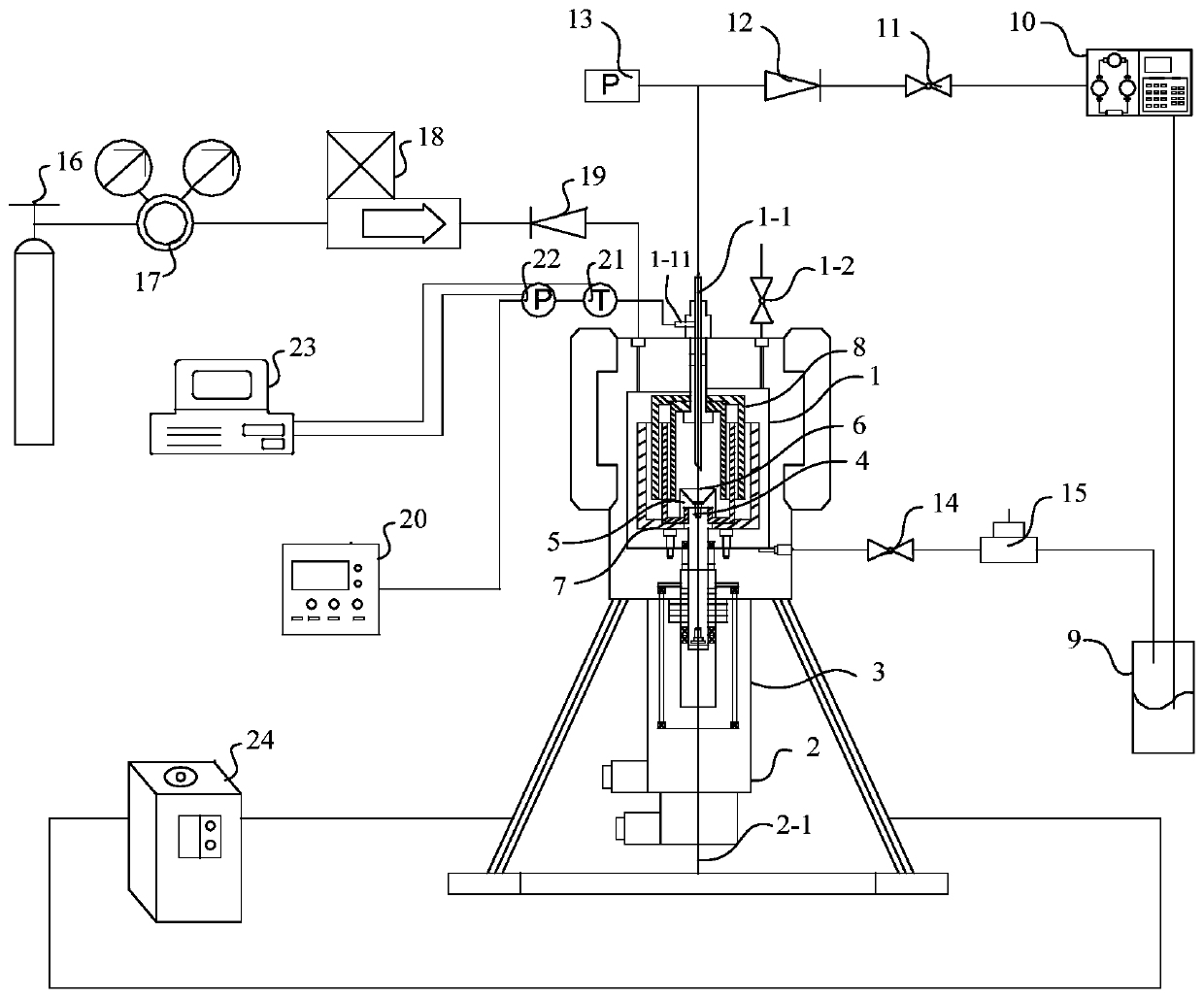

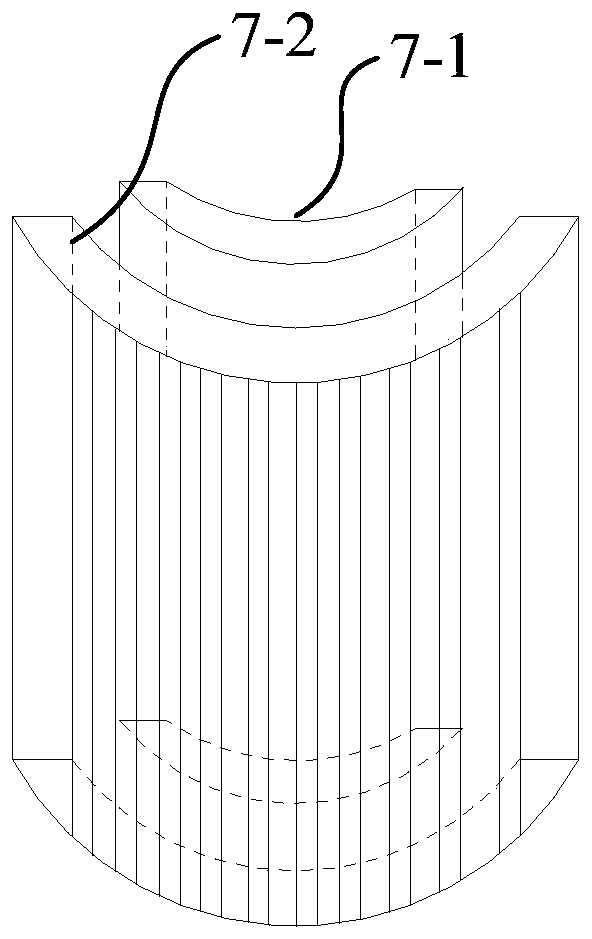

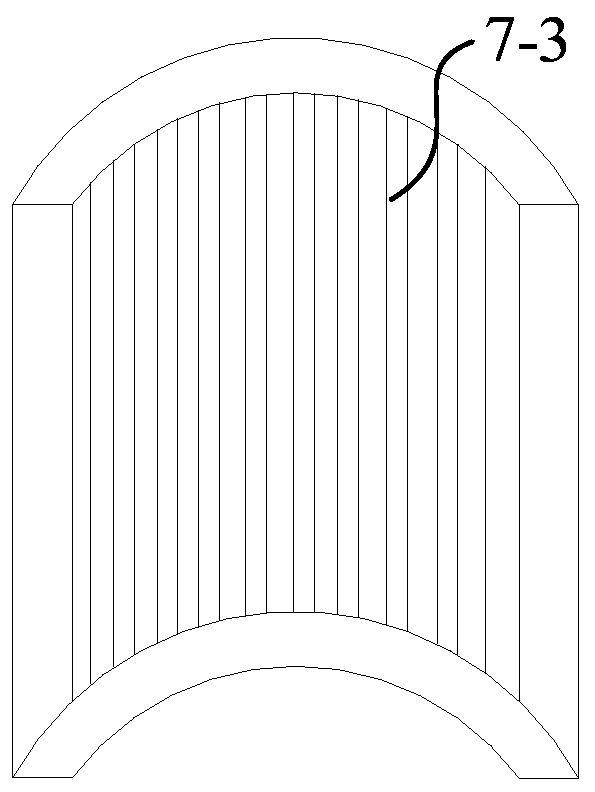

[0035] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention provides a cascaded rotary shearing device for gas hydration separation, combined with figure 1 , figure 2 and image 3 As shown, it includes: reactor 1, motor 2, magnetic stirrer 3, rotating shaft 4, rotor 5, liquid distributor 6, secondary dispersion cylinder 7 and secondary fixed cylinder 8, reactor 1 can be fixed on the support, and the reaction The center of the bottom of the kettle 1 is provided with a rotating shaft 4; the motor 2 drives the motor shaft 2-1 to rotate through the magnetic stirrer 3, and the motor shaft 2-1 passes through the bottom of the kettle to connect to the rotating shaft 4; the center of the upper cover of the reaction kettle 1 is connected to the liquid injection The pipeline 1-1, the liquid injection pipeline 1-1 extends at least to the middle position of the reaction kettle 1 in the axial direction; the rotor 5 is connected to the rotating shaft 4, and the center o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com