A kind of preparation method of bismuth-doped tin-lanthanum gallate yellow phosphor powder for algan chip

The technology of yellow phosphor and lanthanum gallate is applied in the field of preparation of bismuth-doped lanthanum tin gallate yellow phosphor, which can solve the problems of increased packaging difficulty, strong scattering, environmental damage, etc., and achieves low price, simple preparation process, Avoid overlapping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

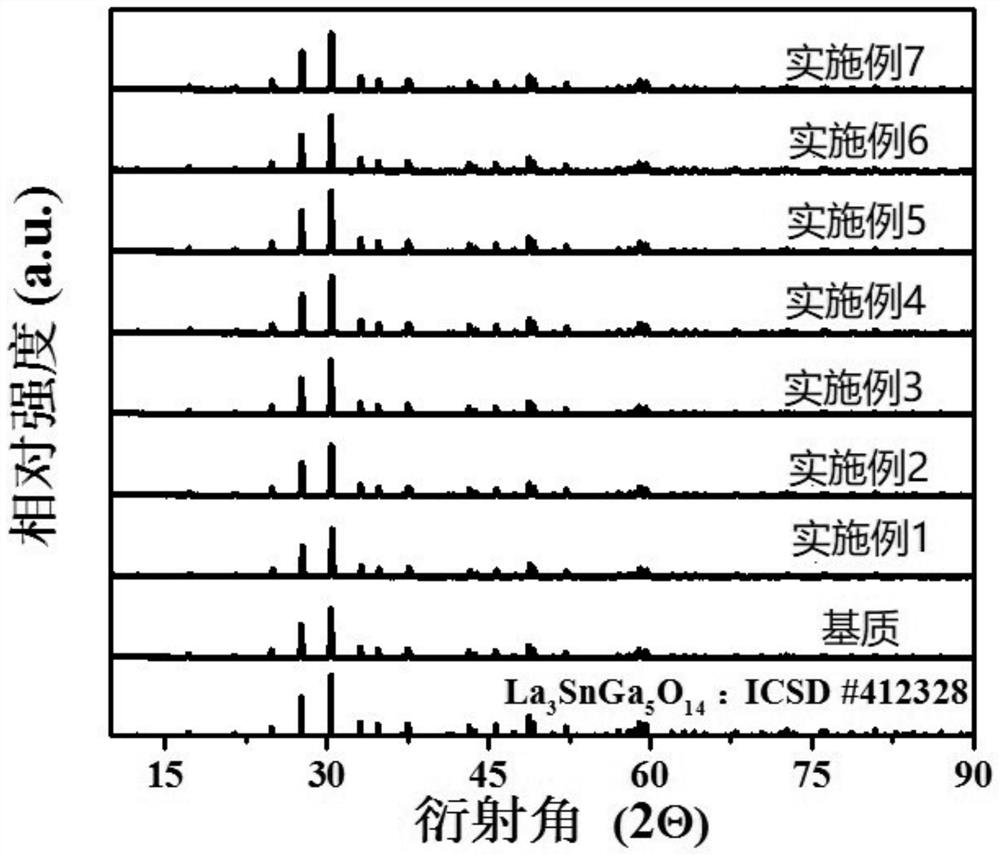

[0029] A method for preparing bismuth-doped lanthanum tin gallate yellow phosphor for AlGaN chips, specifically comprising the following steps:

[0030] S1), according to the molar ratio of elements La:Sn:Ga:Bi=2.997:1:5:0.003, that is, x=0.1%, respectively take lanthanum oxide, tin oxide, gallium oxide and bismuth trioxide as raw materials, the mixture 3g;

[0031] S2), grind and mix the compound in step S1) and put it into a jade crucible, then put the crucible into a high-temperature electric furnace, and pre-fire it in an air atmosphere for 4 hours, and the pre-fire temperature is 800°C;

[0032] S3), take out the pre-fired sample in step S2), grind and mix it evenly, put it into a crucible and burn it under air atmosphere for 7 hours, the burning temperature is 1400°C;

[0033] S4), taking out the burned sample in step S3) and cooling it naturally, grinding and mixing to obtain yellow fluorescent powder La 3 SnGa 5 o 14 : Bi 3+ .

Embodiment 2

[0035] A method for preparing bismuth-doped lanthanum tin gallate yellow phosphor for AlGaN chips, specifically comprising the following steps:

[0036] S1), according to the element molar ratio is La: Sn: Ga: Bi=2.991:1:5:0.009, that is, x=0.3%, respectively take lanthanum oxide, tin oxide, gallium oxide and bismuth nitrate as raw materials, the mixture is 3g;

[0037] S2), grind and mix the compound in step S1) and put it into a jade crucible, then put the crucible into a high-temperature electric furnace, and pre-fire it in an air atmosphere for 6 hours, and the pre-fire temperature is 700°C;

[0038] S3), take out the pre-fired sample in step S2), grind and mix it evenly, put it into a crucible and burn it under air atmosphere for 6 hours, the burning temperature is 1450°C;

[0039] S4), taking out the burned sample in step S3) and cooling it naturally, grinding and mixing to obtain yellow fluorescent powder La 3 SnGa 5 o 14 : Bi 3+ .

Embodiment 3

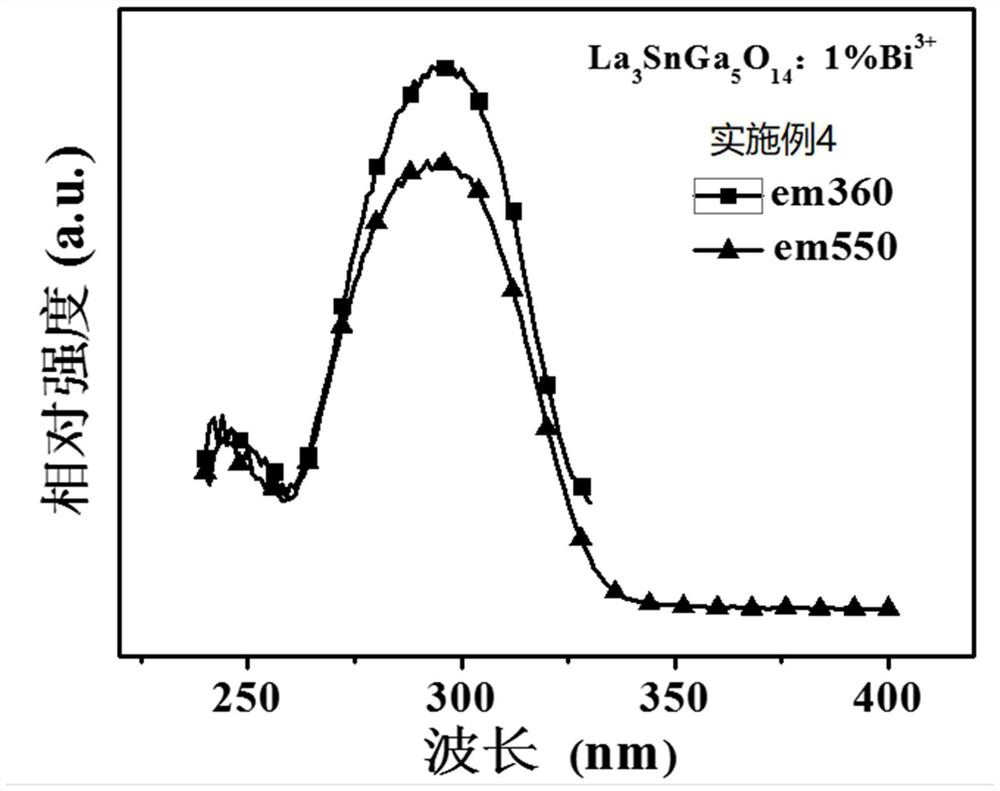

[0041] A method for preparing bismuth-doped lanthanum tin gallate yellow phosphor for AlGaN chips, specifically comprising the following steps:

[0042] S1), according to the molar ratio of elements La:Sn:Ga:Bi=2.985:1:5:0.015, i.e. x=0.5%, respectively take lanthanum oxide, tin oxide, gallium oxide and bismuth trioxide as raw materials, the mixture 3g;

[0043] S2), grind and mix the compound in step S1) and put it into a jade crucible, then put the crucible into a high-temperature electric furnace, and pre-fire it in an air atmosphere for 7 hours, and the pre-fire temperature is 700°C;

[0044] S3), take out the pre-fired sample in step S2), grind and mix it evenly, put it into a crucible and burn it under air atmosphere for 7 hours, the burning temperature is 1400°C;

[0045] S4), taking out the burned sample in step S3) and cooling it naturally, grinding and mixing to obtain yellow fluorescent powder La 3 SnGa 5 o 14 : Bi 3+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com