Composite sound insulation wallboard for dividing ship cabin

A technology for cabins and ships, which is applied in the field of noise control in ship cabins. It can solve the problems that the fire performance cannot meet the requirements of marine B15 grade, and the density of rock wool is too high to meet the requirements. It achieves low density, low thermal conductivity and improved sound insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

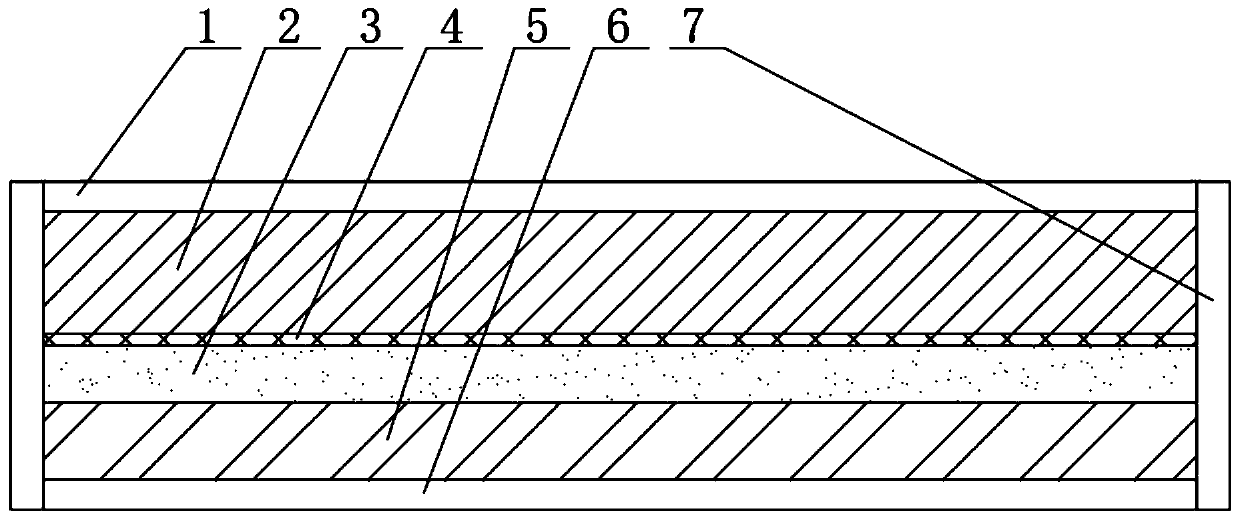

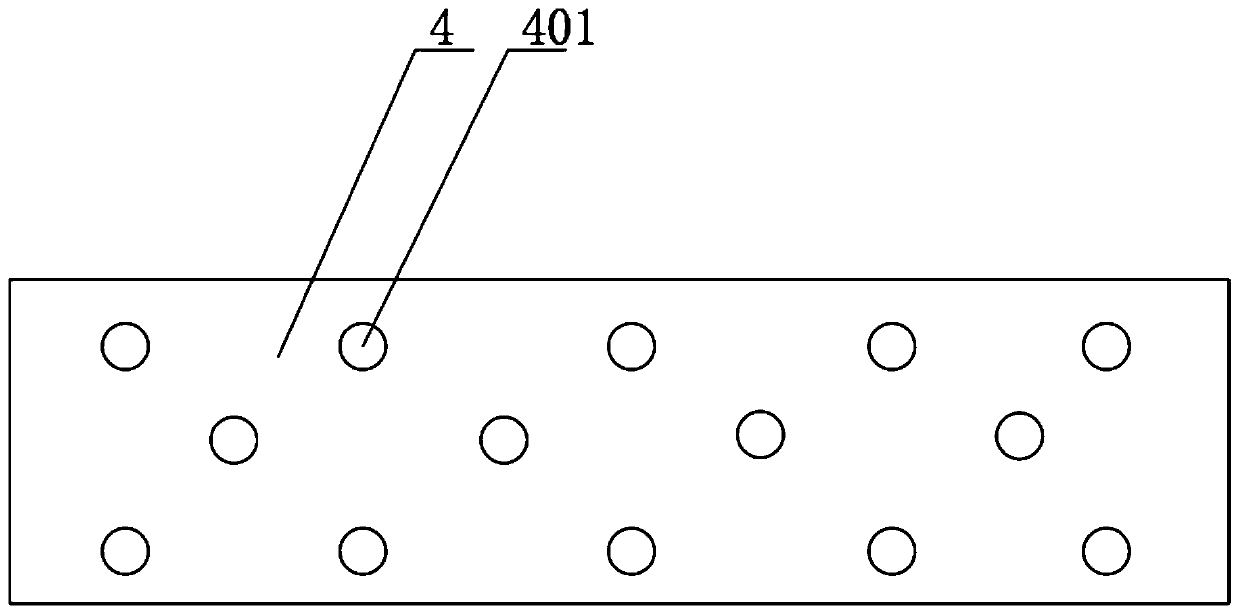

[0032] Such as figure 1 with figure 2 As shown, the composite sound-insulating wall panel used for the division of the ship cabin in this embodiment includes a lower panel 6, a rock wool layer 5 is arranged on the upper part of the lower panel 6, and a micro-perforated plate 4 is arranged at a distance above the rock wool layer 5. A glass wool layer 2 is installed above the perforated plate 4, and an upper panel 1 is installed on the top surface of the glass wool layer 2. The upper panel 1 is parallel to the lower panel 6, and side panels are welded on both sides of the upper panel 1 and the lower panel 6 respectively. 7. At the same time, both sides of the rock wool layer 5 and the glass wool layer 2 are bonded to the side panel 7, and the two sides of the micro-perforated plate 4 are welded to the side panel 7; the top of the rock wool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com