Mud atomizing spray head for preparing large ceramic plate and spray gun using same

A technology for atomizing nozzles and mud, applied in the field of mud atomizing nozzles and spray guns, can solve the problems of low natural bulk density of powder, poor granulation effect, poor atomization effect, etc., to improve molding efficiency and yield rate , Improve the atomization effect, improve the effect of shape and gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

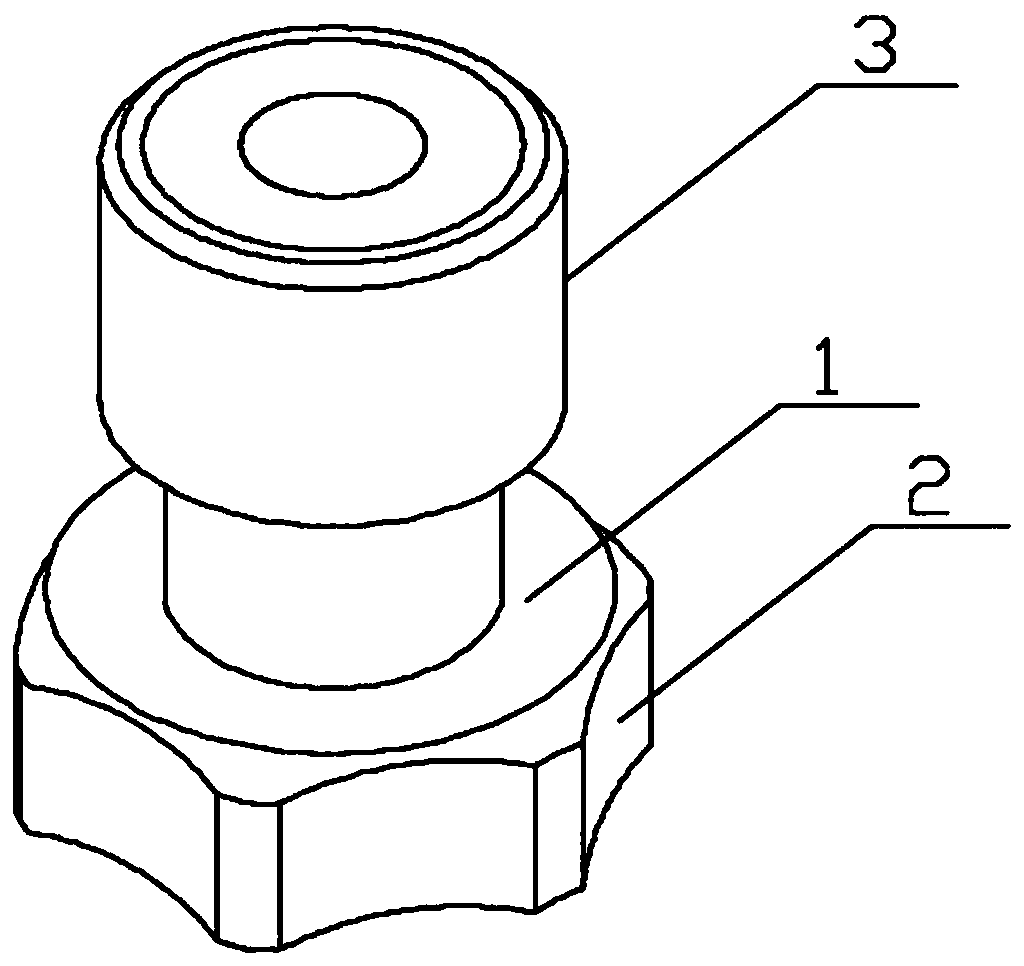

[0031] The invention relates to a slurry atomizing nozzle for preparing large ceramic slabs, which specifically includes a nozzle body (1), a nozzle cover (2), a rotary joint (3), a swirl chamber, a double swirl trough, and a nozzle , the rotating joint is rigidly connected to the upper end of the nozzle body (1), the lower end of the nozzle body (1) is connected to the nozzle cover (2), the nozzle body (1) is hollow, and the hollow part includes a high-speed liquid inlet channel and a rotary In the flow chamber, the double-swirl groove vane is arranged under the swirl chamber, and the nozzle cover (2) is provided with a nozzle, the upper end surface of the nozzle is a tapered structure, and the lower end surface of the nozzle is an arc-shaped outlet.

[0032] The structure of the mud atomization head used in the prior art is generally a low-speed swirl structure, and it is a single-spin groove rotary vane, the thickness of the rotary vane is usually 8-10mm, the size of the noz...

Embodiment 2

[0046] The present invention also relates to the above-mentioned spray gun for preparing the slurry atomizing nozzle of the ceramic slab, the spray gun includes the slurry atomizing nozzle, the water mist nozzle and the hot air nozzle in embodiment 1, and the mud nozzle is located between the water mist nozzle and the spray gun. Between the hot air nozzles, the mud channel of the mud nozzle is connected to the clay storage tank through the mud pipe. The water mist nozzle includes a water spray channel and a cooling air channel connected to the nozzle end. The water spray channel is connected to the water pump through the water pipe, and the water pump is connected to the water tank. , the cold air channel and the hot air channel of the hot air nozzle are connected with the air pump through the air pipe, and the outer peripheral side of the mud channel of the mud nozzle and the outer peripheral side of the hot air channel of the hot air nozzle are equipped with resistance wires. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com