Supported composite transition metal oxide, preparation method and application thereof as catalyst

A transition metal and transition metal salt technology, applied in the field of supported composite transition metal oxides and preparation, can solve problems such as the aggregation of catalyst active components, achieve high catalytic activity and stability, have both stability, and promote catalytic combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] (1) Preparation of zeolite molecular sieve carrier: first weigh 0-6.4g of F127 in a beaker, then add 32g of deionized water and keep stirring until F127 is completely dissolved. At the same time, take another beaker and weigh 0-0.51g of aluminum isopropoxide and 5.2-31.2g of tetraethyl orthosilicate (TEOS) and stir evenly. After F127 is completely dissolved, add the mixed solution dropwise into the F127 aqueous solution. After several hours of vigorous stirring, 2.0-8.2 g of tetrapropylammonium hydroxide solution (TPAOH) was added, and the stirring was continued until it became a gel. The whole stirring process is carried out at 20-100°C. The obtained wet gel is aged at 20-100° C. for 4-10 hours, and then dried at 60-120° C. until the weight of the dry gel remains unchanged. The xerogel obtained through the above steps is treated with a steam-assisted method at 140-200° C. for 12-24 hours. After the product is washed and filtered, it is dried at 60-120°C. Finally, th...

Embodiment 1

[0038] Take 1g of multi-level porous ZSM-5 powder in a mortar, weigh 0.54g of cobalt nitrate hexahydrate and 0.295g of potassium permanganate into the mortar, grind to a uniform state, transfer to a 10mL crucible after low-temperature vacuum drying, and Place in a high-pressure reaction kettle, add 1.6g of ammonia water into the kettle, and place the reaction kettle at 140°C for 6 hours. In a closed high-temperature environment, the ammonia water will decompose and volatilize, forming an alkaline environment with the water volatilized into the environment. , during the heating process, the aqueous solution does not penetrate into the crucible. Cobalt nitrate hexahydrate and potassium permanganate undergo a redox reaction in this alkaline environment to obtain a composite oxide, and the sample is transferred to 60°C for drying.

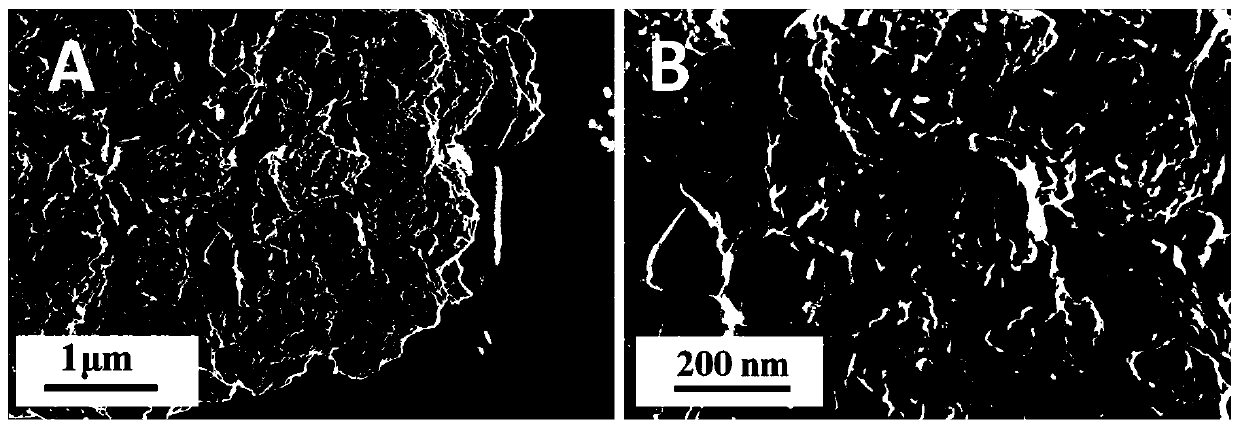

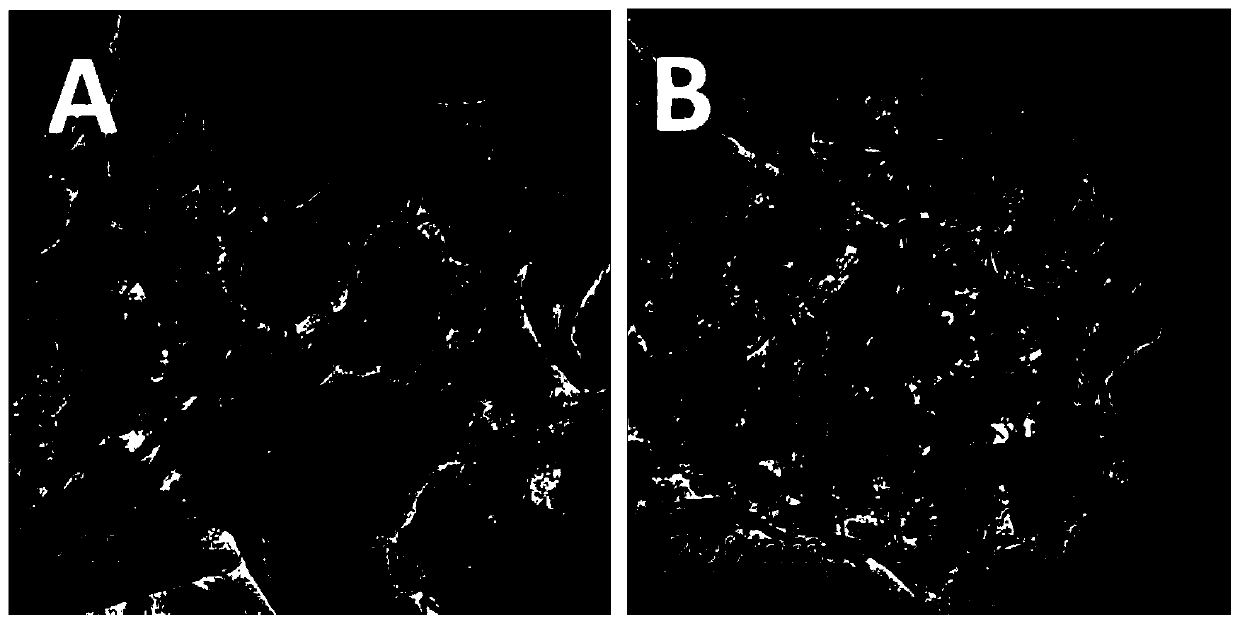

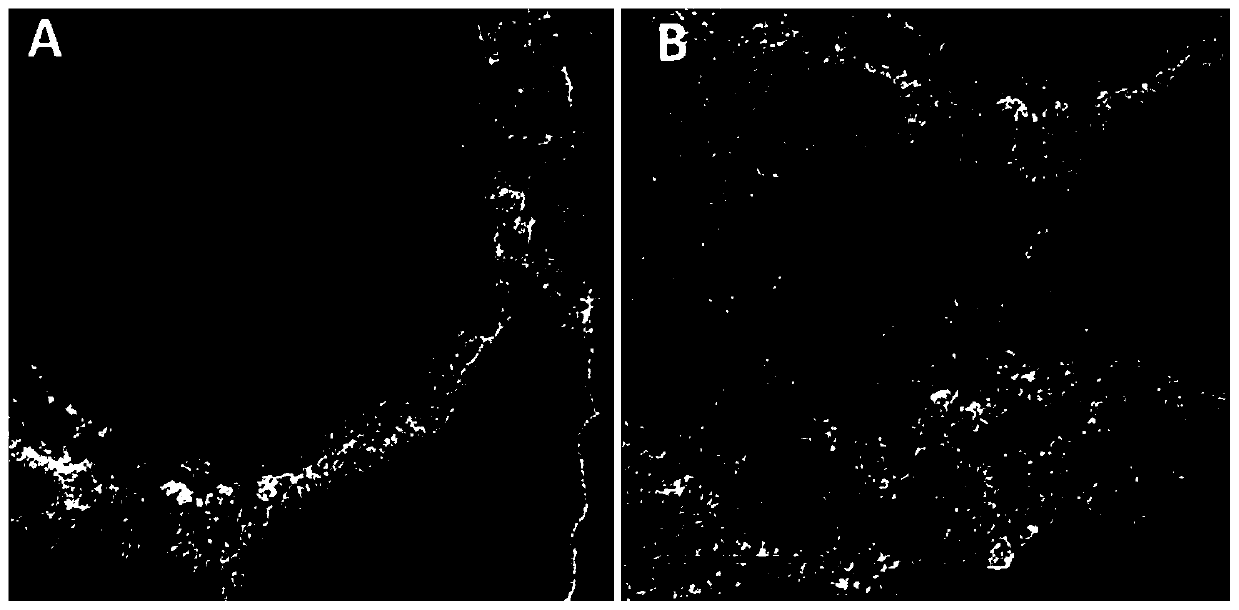

[0039] According to the method of embodiment case 1, obtain the catalyst prepared by oxidation-reduction method, SEM photo is as follows figure 1 shown...

Embodiment 2

[0044] Weigh 0.075 g (40-60 mesh) of the catalyst prepared by the method of Example 1 and the comparative example, and test the catalytic oxidation activity of toluene in a fixed bed reactor. The reaction conditions were 400 ppm toluene / 20% oxygen / 1.58% water / nitrogen, and the total flow rate was 100 mL / min. The reaction space velocity is 80000mL / (g.h). Activity curve as Figure 4 shown by Figure 4 It can be known that the catalytic combustion performance of the catalyst prepared by the method of the present invention is far superior to that of the comparative catalyst. It can be seen that the catalyst in Example 1 completely converts toluene at 280°C, T 90 and T 50 258 and 252°C, respectively. The catalyst of the comparative example needs to convert the toluene in the reaction gas completely at 320°C, and its T 90 and T 50 They are 319 and 310°C, respectively, which are much higher than the catalyst of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com