Protein powder and preparation method thereof

A protein powder and base material technology, applied in food science and other fields, can solve problems such as poor fluidity and slow protein powder dissolution speed, and achieve the effects of improved fluidity, sustainable development, and improved experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

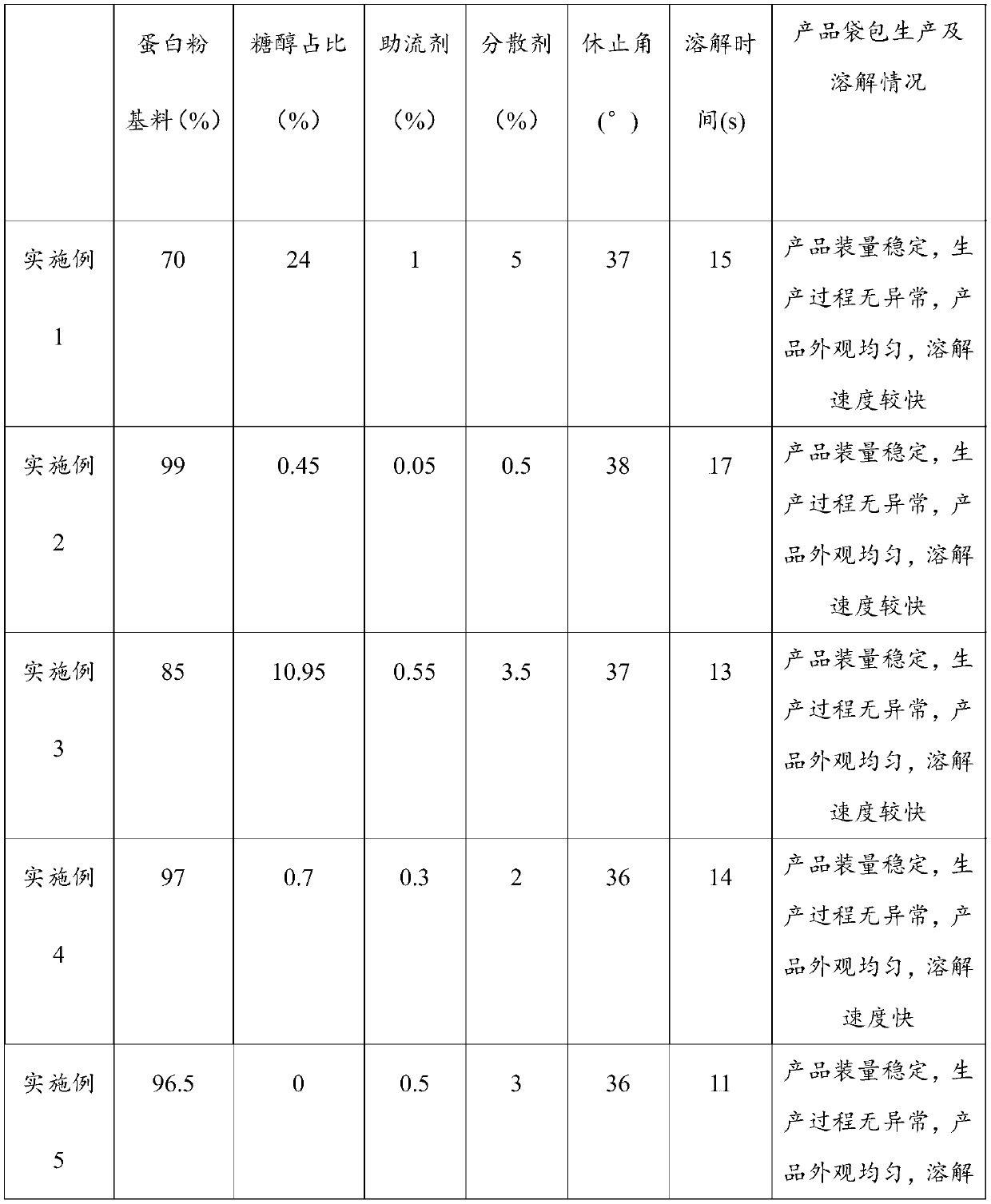

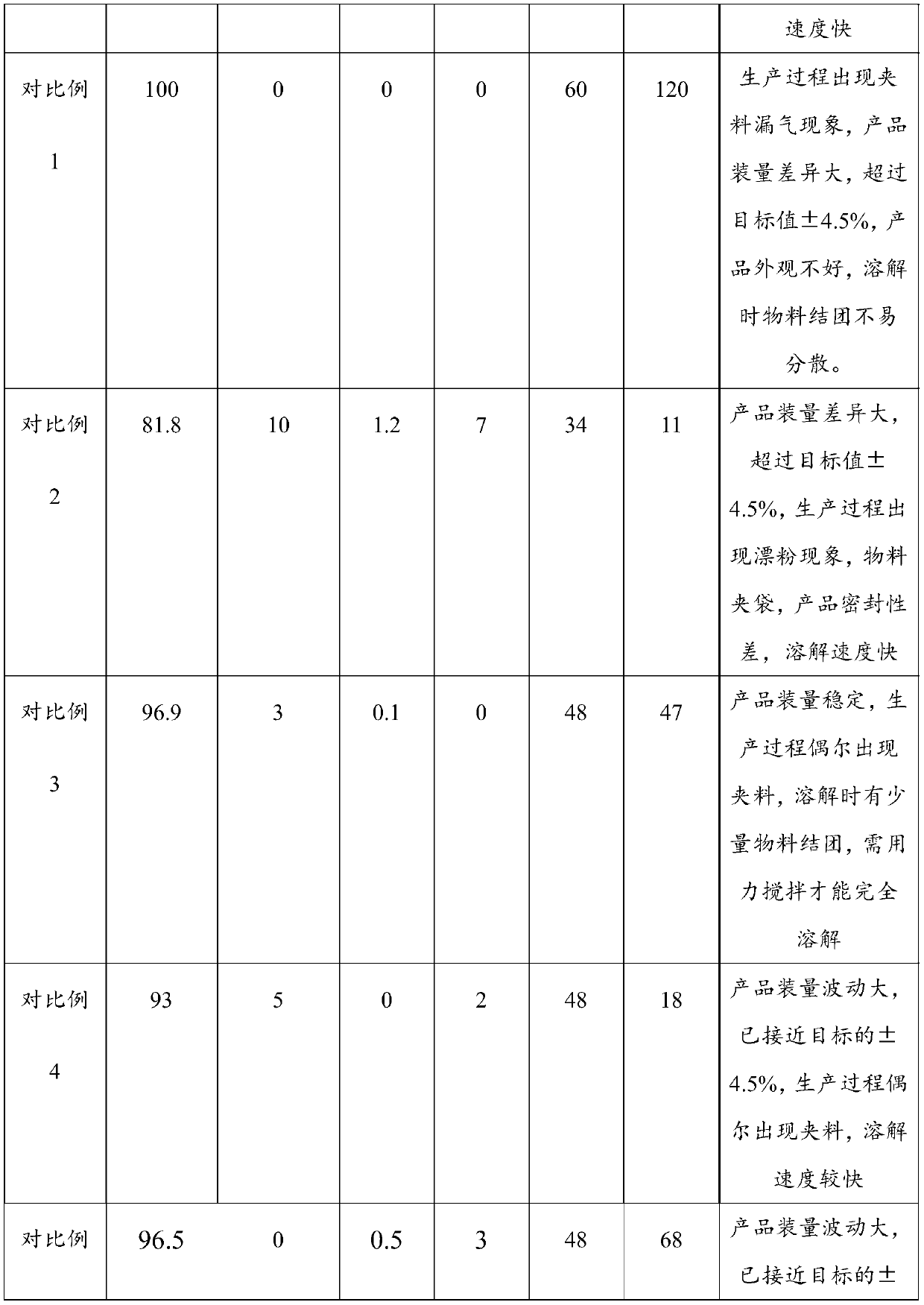

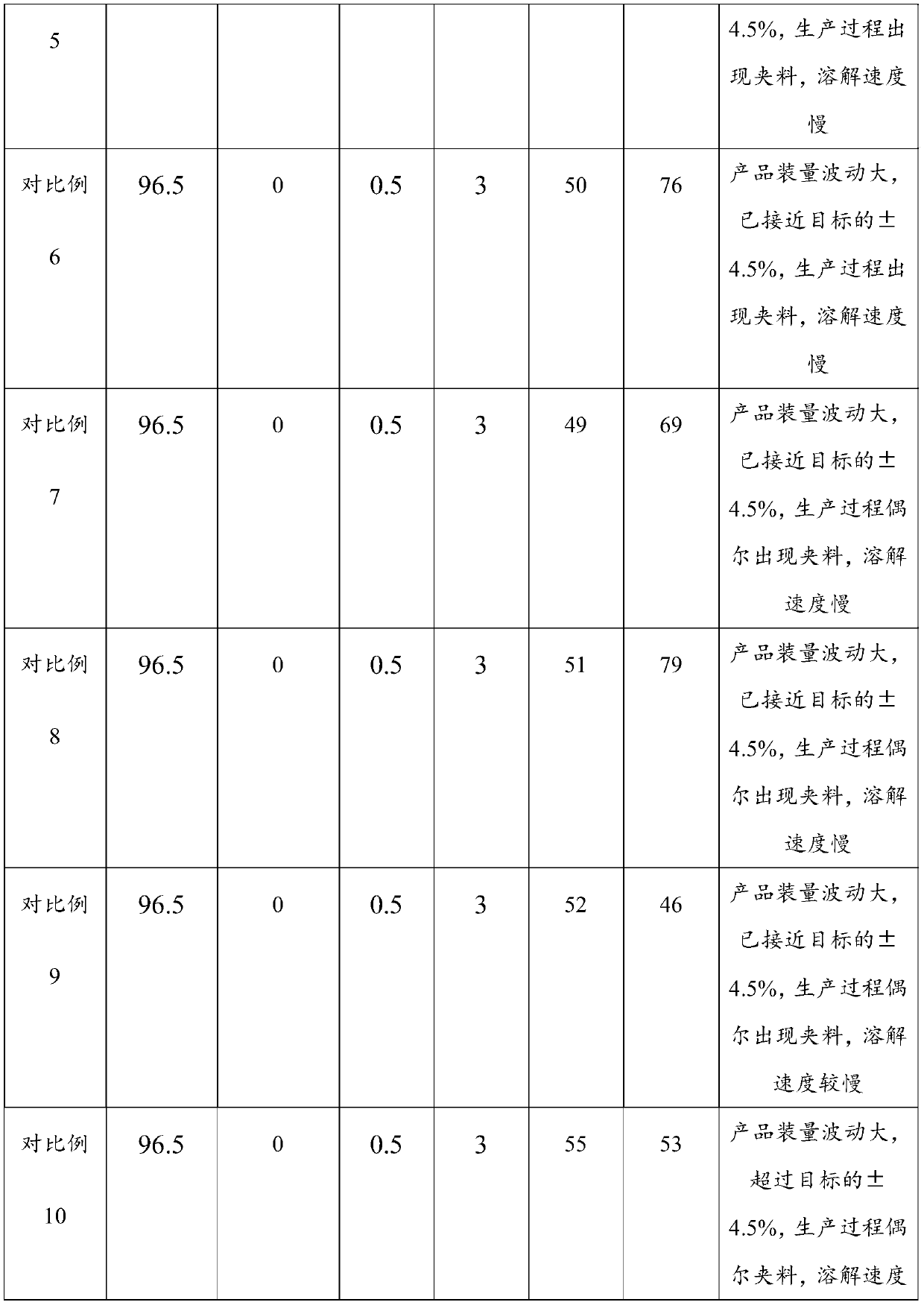

Examples

Embodiment 1

[0036] The protein powder base (soy protein isolate), sugar alcohol (sorbitol), glidant (silicon dioxide) and dispersant (milk mineral salt) are weighed and batched, and the glidant and dispersant are mixed , then add sugar alcohol and protein powder base material for total mixing, the speed of total mixing is 8rpm, the time is 10min, the total mixing is until the color is uniform, and then the material is discharged, and the protein powder after the total mixing is bagged by a fully automatic packaging machine, and the production The speed is 45-60 bags / min, and the filling volume is within the range of ±4.5% of the target value to obtain the bagged protein powder. Among them, the mass ratio of protein powder base material, sugar alcohol, glidant and dispersant is 70:24:1:5.

Embodiment 2

[0038] In this example, protein powder in bags is prepared. The raw materials and steps are the same as in Example 1, but the mass ratio of protein powder base material, sugar alcohol, glidant and dispersant is 99:0.45:0.05:0.5.

Embodiment 3

[0040] In this example, protein powder in bags is prepared. The raw materials and steps are the same as in Example 1, but the mass ratio of protein powder base material, sugar alcohol, glidant and dispersant is 85:10.95:0.55:3.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com