In-situ leaching uranium mining closed loop circulating pumping and injecting system and method

A closed-circuit circulation and in-situ leaching uranium mining technology, which is applied in separation methods, chemical instruments and methods, and mining fluids, can solve problems such as high safety and environmental protection risks, long infrastructure construction periods, and large land occupation, so as to save land occupation , Reduce environmental damage and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A closed-circuit pumping system and method for in-situ leaching uranium mining according to the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

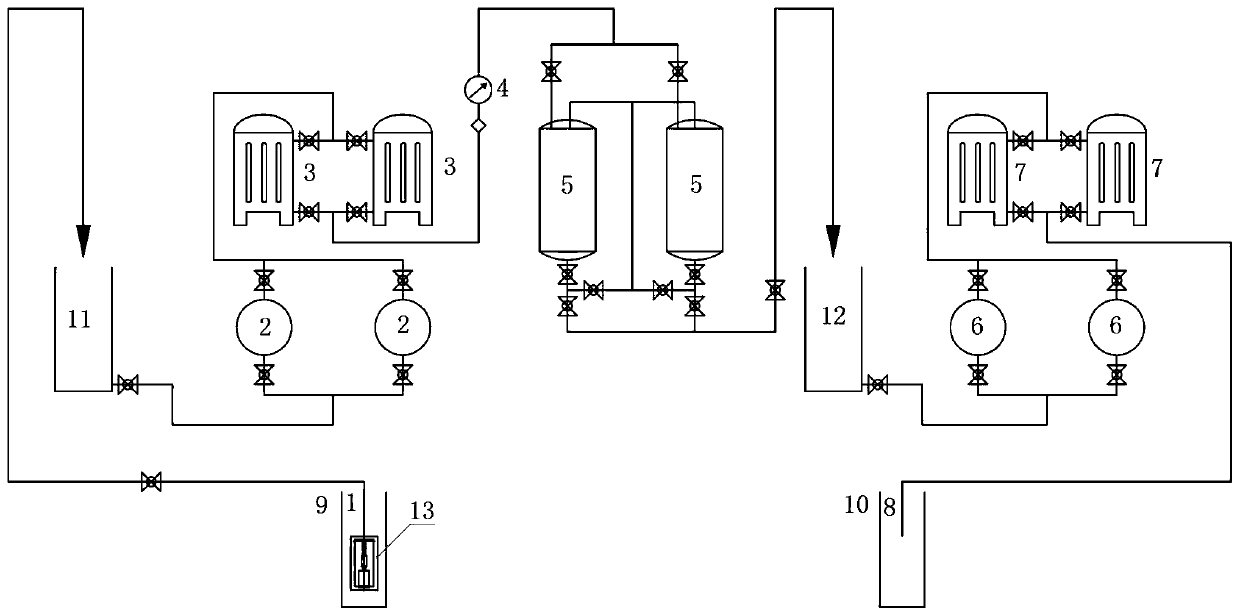

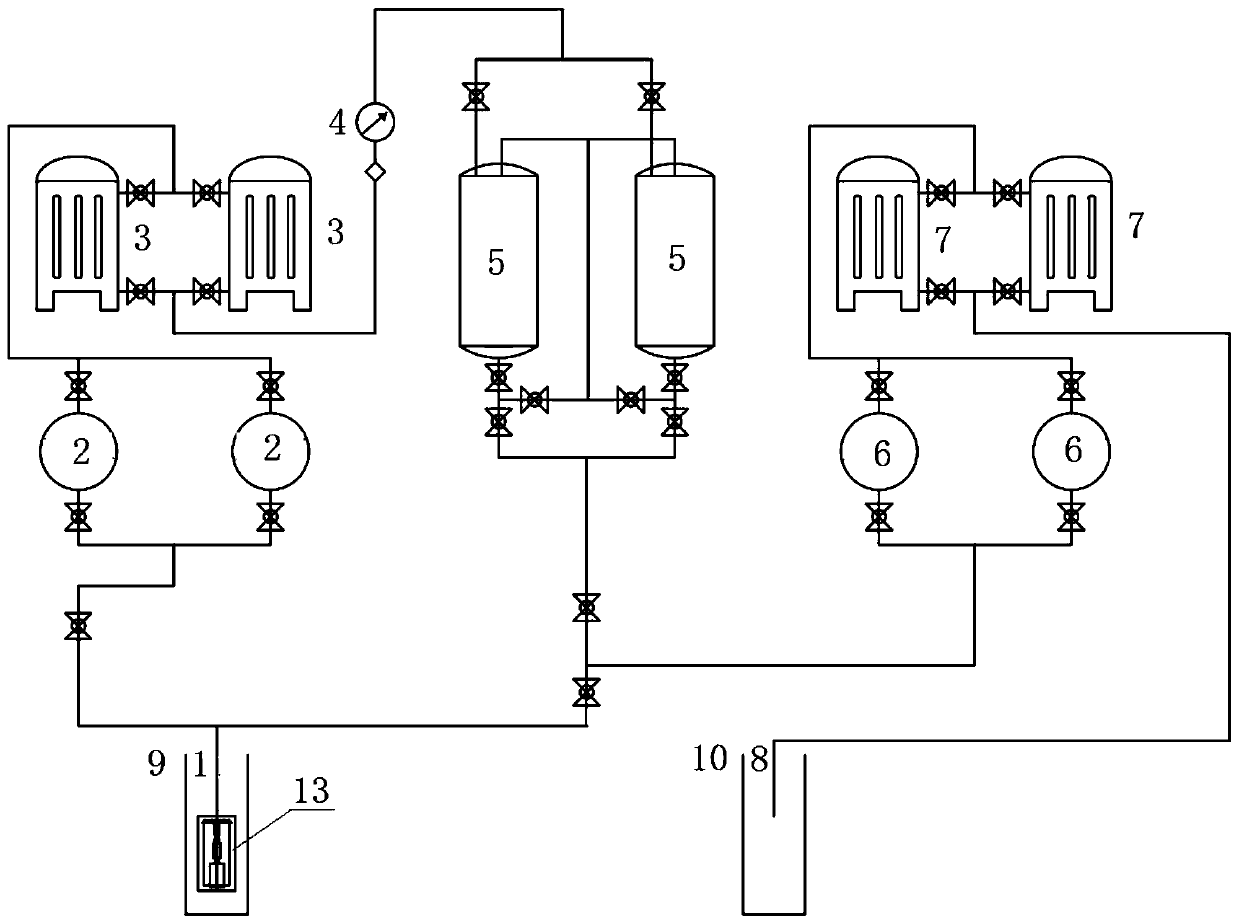

[0035] Such as figure 2 As shown, a closed loop pumping system for in-situ leaching uranium mining includes a pumping system, an ion exchange system and a liquid injection system;

[0036] The pumping system includes a pumping well 9, a submersible pump 13, a pumping hole 1, a raw liquid pump 2 and a raw liquid filter 3;

[0037] Described ion exchange system comprises adsorption tower 5 and the resin placed in adsorption tower 5;

[0038] The liquid injection system includes a liquid injection pump 6, a liquid injection filter 7, a liquid injection hole 8 and a liquid injection well 10;

[0039] Among them, the submersible pump 13 is placed in the liquid pumping well 9, and after connecting the raw liquid pump 2, the raw liquid filter 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com