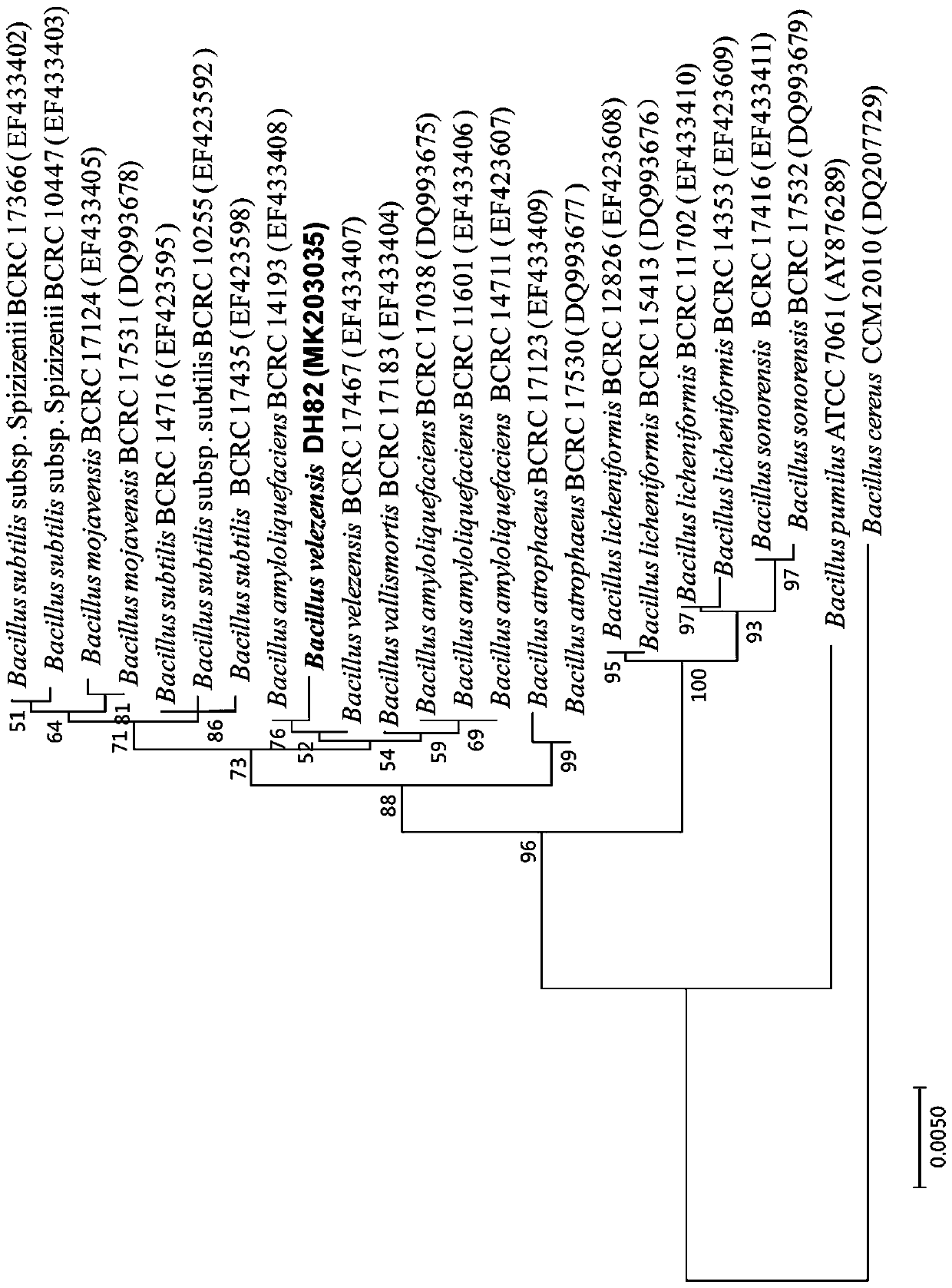

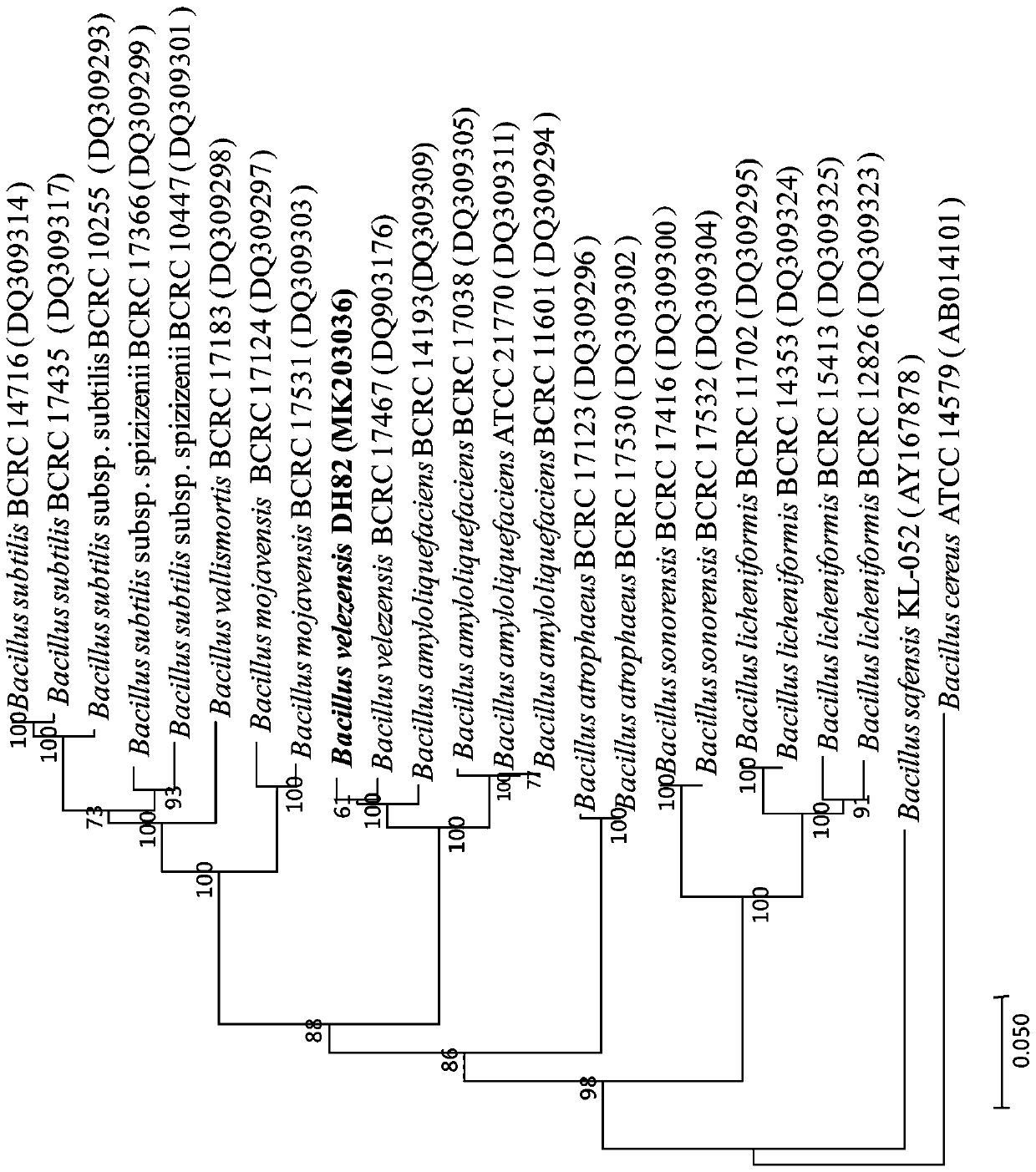

Bacillus velezensis DH82 and preparation method and application of antibacterial protein thereof

A technology of Bacillus and DH82, applied in the field of preparation of Bacillus velesi DH82 and its antibacterial protein, can solve the problems of no Bacillus velesi and few prevention and control patents, etc., to improve immunity and protect the body. The effect of healthy growth and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

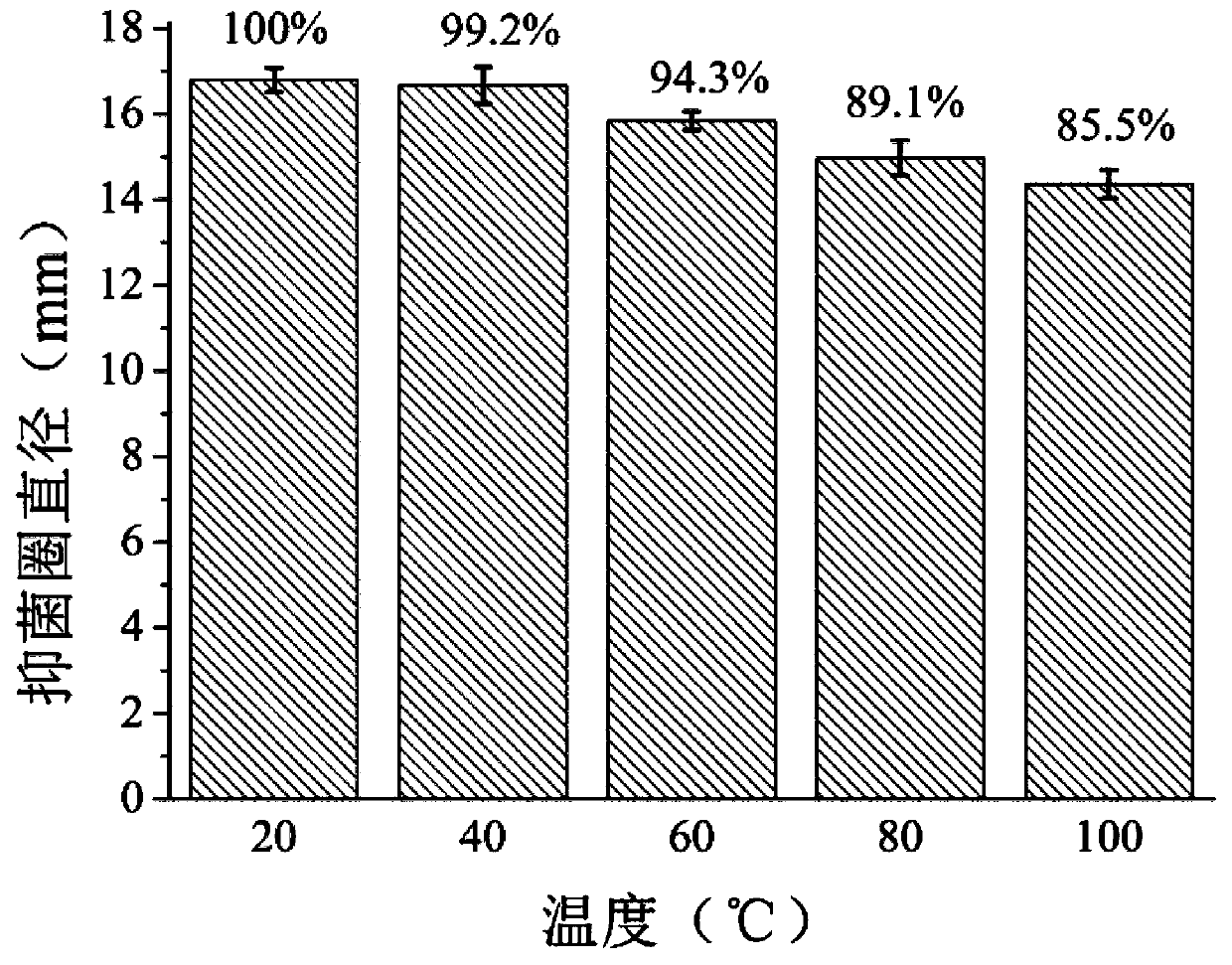

Examples

preparation example Construction

[0037] (2) Preparation of fermentation supernatant: Inoculate the activated bacterial liquid in step (1) into the improved LB medium at 1-5% (V / V), 25-40°C, 150-220rpm, 10-35h, All fermentation broths were centrifuged at 5000-12000rpm, 4°C for 10-30min, and the supernatant was filtered through a 0.22μm microporous membrane to obtain the fermentation supernatant;

[0038] (3) Preparation of antibacterial protein: in step (2) fermentation supernatant 50 ~ 2000mL, add solid ammonium sulfate to make solution ammonium sulfate saturation reach 40 ~ 100%, 4 ℃ overnight, centrifuge 20 ~ 30min at 6000 ~ 10000rpm to get The precipitate was dissolved in ultrapure water, dialyzed with a 3000Da dialysis bag for 24-48 hours, and freeze-dried to obtain the antibacterial protein.

[0039] The LB medium component used in the embodiment of the present invention is: 1% peptone, 0.5% yeast powder, 1% sodium chloride, pH7.3; the improved LB medium component is: 1% tryptone, 0.5% yeast powder, 0.5...

Embodiment 1

[0041] Embodiment 1: the preparation of antibacterial protein

[0042] (1) Fermentation supernatant: take Bacillus Velez DH82 and inoculate it on the improved LB medium, 25°C, 150rpm, 16h, then inoculate the improved LB medium according to the inoculation amount of 5% (V / V), After 35 hours at 25°C and 220rpm, all the fermentation broth was centrifuged at 5000rpm and 4°C for 30min, and the supernatant was filtered through a 0.22μm microporous membrane to obtain the fermentation supernatant;

[0043] (2) Antibacterial protein: Add solid ammonium sulfate to the fermentation supernatant to make the ammonium sulfate saturation of the solution reach 40%, overnight at 4°C, centrifuge at 6000rpm for 30min to obtain a precipitate, dissolve it in ultrapure water, dialyze with a 3000Da dialysis bag for 24h, freeze-dry get antimicrobial protein.

Embodiment 2

[0044] Embodiment 2: antibacterial protein preparation

[0045] (1) Fermentation supernatant: take Bacillus Velez DH82 and inoculate it on the improved LB medium, 40°C, 220rpm, 8h, inoculate the improved LB medium according to 1% (V / V) inoculum, 40 ℃, 150rpm, after 10h, all the fermentation broth was centrifuged at 12000rpm, 4℃ for 10min, and the supernatant was filtered through a 0.22μm microporous membrane to obtain the fermentation supernatant;

[0046] (2) Antibacterial protein: Add solid ammonium sulfate to the fermentation supernatant to make the ammonium sulfate saturation of the solution reach 100%, overnight at 4°C, centrifuge at 10000rpm for 20min to obtain a precipitate, dissolve it in ultrapure water, dialyze with a 3000Da dialysis bag for 48h, freeze-dry get antimicrobial protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com