Convective bonded steam drum generator

A technology of generating device and steam drum, which is applied in grease/oily substance/float removal device, separation method, flotation water/sewage treatment, etc., can solve the problems of equipment failure, damage to the environment, irritating strong fatty acid, etc. To achieve the effect of fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

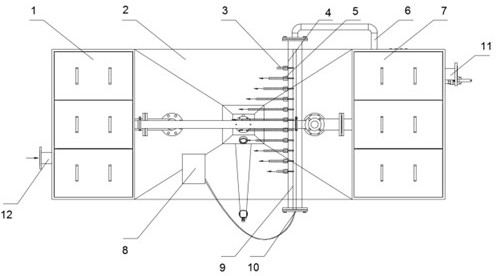

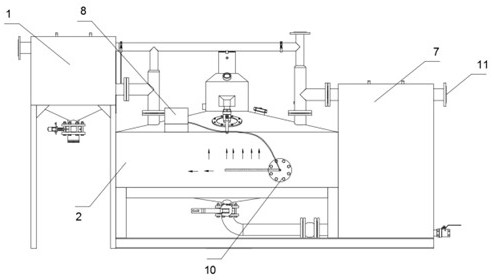

[0027] like figure 1 As shown, in the embodiment of the present invention, the convective bonding steam drum generating device includes an oil-water separation bin 2, the upper end of the oil-water separation bin 2 is equipped with a generating device fixing pipe 4, and the generating device fixing pipe 4 is installed with an air guide pipe 9 inside. The air guide tube 9 is connected with a micro-bubble guide tube 3 distributed in an array, and a bubble stone 5 is installed at the connection between the micro-bubble guide tube 3 and the air tube 9, and the two ends of the generating device fixing tube 4 are respectively provided with a pressurized water flow inlet Tube 6 and air pump 8.

[0028] The air pump 8 generates a fixed value gas according to the processing capacity of the oil-water separator, and enters the air duct 9 at the position of the installation flange 10. The air stone 5 crushes the air and generates micro-bubbles. The water flow (the flow rate is very small...

Embodiment 2

[0031] Convective bonding steam drum generator, such as figure 1 and figure 2 As shown, the embodiment of the present invention is further limited on the basis of Embodiment 1.

[0032] Further, a solid-liquid separation chamber 1 is installed at the left end of the oil-water separation chamber 2, the solid-liquid separation chamber 1 is communicated with the oil-water separation chamber 2, an inlet pipe 12 is installed at the left end of the solid-liquid separation chamber 1, and a lower end of the solid-liquid separation chamber 1 is installed with Four support legs arranged in a rectangular array.

[0033] Further, a sewage lifting bin 7 is installed at the right end of the oil-water separation bin 2, the sewage lifting bin 7 is communicated with the oil-water separation bin 2, the sewage lifting bin 7 is communicated with the pressurized water flow inlet pipe 6, and the right side wall of the sewage lifting bin 7 is connected. An outlet pipe 11 is installed.

[0034] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com