Molten Pool Treatment Method Based on Laser Transmission Welding of Plastics

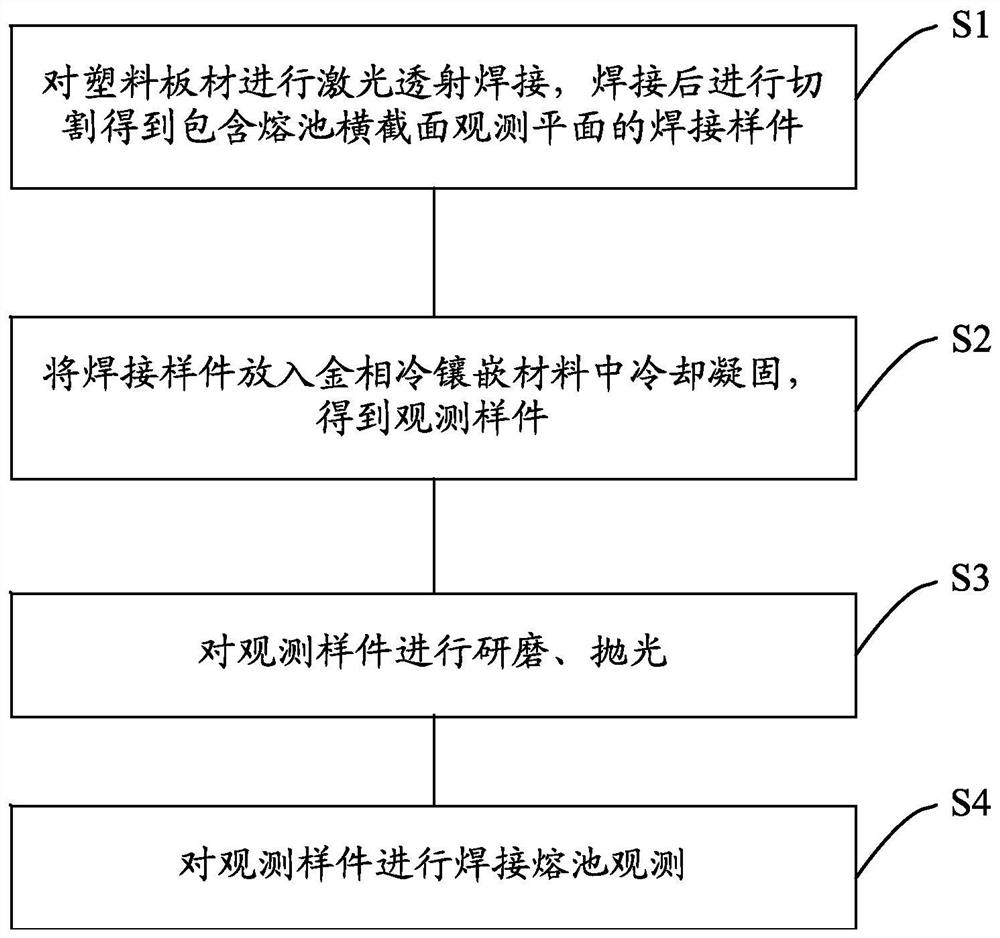

A technology of laser transmission welding and processing method, which is applied in the field of molten pool processing based on laser transmission welding plastics, can solve the problems of blurred outline, rough surface of observation results, and difficulty in clearly observing the shape of molten pool, etc., and meets the requirements of equipment cost Low, reliable observation results, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

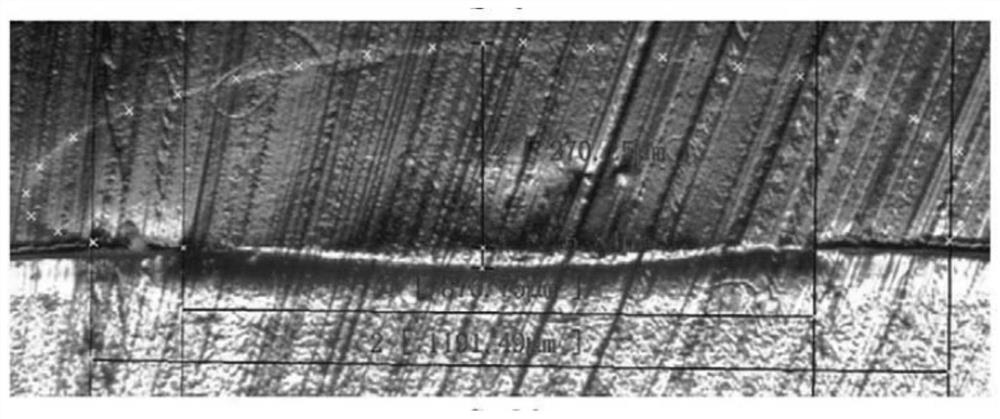

[0074] 1. Carry out laser transmission welding on the transparent PC plastic board, add aluminum powder and carbon black mixed powder in the middle of the lower two layers of PC plastic board, the mass ratio of aluminum powder and carbon black is 1:4, and cut and process on the welded sample Obtain the welding sample including the observation plane of the molten pool cross section;

[0075] 2. Place the welding sample in step 1 in absolute ethanol, clean it with an ultrasonic cleaner for 3 minutes, and place it in a constant temperature blast drying oven to dry;

[0076] 3. Mix and stir acrylic powder (GORAL / A90045) and liquid enhancer (GORAL / A90340) at a mass ratio of 1:1 to make a metallographic cold mounting material, and place it in a cylindrical mosaic mold, bake it in step 2 The dried welding sample is placed on the top of the metallographic cold mounting material, and after the mounting material is cooled and solidified, a cylindrical observation sample is formed. The ...

Embodiment 2

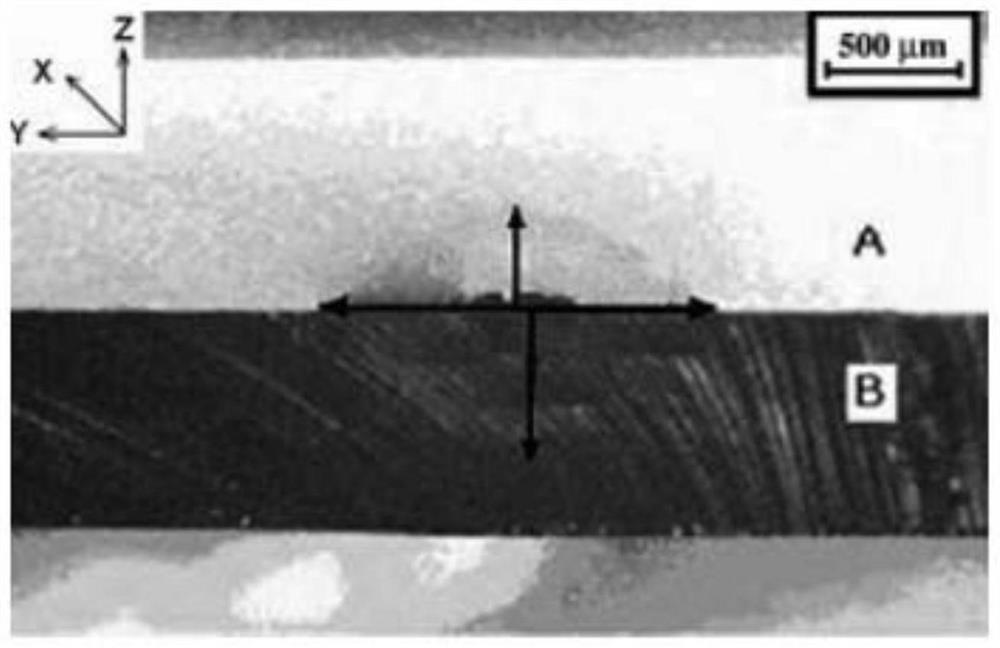

[0082] 1. Carry out laser transmission welding on the transparent PC plastic board, add a metal aluminum film layer in the middle of the lower two PC plastic boards, cut and process the welding sample including the observation plane of the cross-section of the molten pool on the welded sample;

[0083] 2. Place the welding sample in step 1 in absolute ethanol, clean it with an ultrasonic cleaner for 3 minutes, and place it in a constant temperature blast drying oven to dry;

[0084] 3. Mix and stir acrylic powder (GORAL / A90045) and liquid enhancer (GORAL / A90340) at a mass ratio of 1:1 to make a metallographic cold mounting material, and place it in a cylindrical mosaic mold, bake it in step 2 The dried welding sample is placed on the top of the metallographic cold mounting material, and after the mounting material is cooled and solidified, a cylindrical observation sample is formed. The mosaic mold in this embodiment has an outer diameter of 34mm, an inner diameter of 25mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com