Three-directional near-isotropy high-performance aluminum alloy cylindrical forge piece manufacturing process

A manufacturing process and technology of aluminum alloy, which is applied in the field of manufacturing process of three-way nearly isotropic high-performance aluminum alloy cylindrical forgings, can solve the problem of extremely high equipment capacity requirements of ring rolling mills, large dimensions in the height direction of cylindrical forgings, and loss of radial elongation Indicators and other issues to achieve the effect of tapping material potential and high peak strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

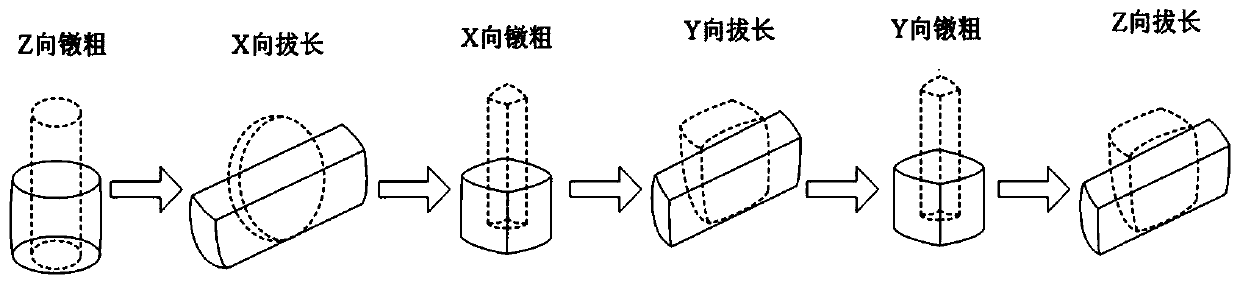

Method used

Image

Examples

Embodiment 1

[0106] Taking the 2A14 aluminum alloy tubular forging, a key part of a key model of the Air Force, as an example, the finished product size is Φ1040×Φ870×1000mm, including the following steps:

[0107] Step 1: Raw material size design:

[0108]The aluminum alloy round ingot produced by the semi-continuous casting method as the raw material, considering the structural size of the part, the consumption of the forging process, and the machining allowance, requires the height-to-diameter ratio of the ingot L / D=2, the diameter of the ingot is Φ600mm, and the height is 1200mm;

[0109] Step 2: Ingot Quality Inspection:

[0110] The state of the ingot is annealed, and the quality of the ingot is being controlled;

[0111] Step 3: Heating the ingot before forging:

[0112] The ingot is installed in the furnace at room temperature. The heating process is divided into two stages. The first stage: from room temperature to 430°C for 2 hours, and keep it for 1 hour; the second stage, tak...

Embodiment 2

[0150] Taking the 2A14 aluminum alloy tubular forging, a key part of a key model of the Air Force, as an example, the finished product size is Φ1040×Φ870×1000mm, including the following steps:

[0151] Step 1: Raw material size design:

[0152] The aluminum alloy round ingot produced by the semi-continuous casting method as the raw material, considering the structural size of the part, the consumption of the forging process, and the machining allowance, requires the height-to-diameter ratio of the ingot to be L / D=3, the diameter of the ingot to be Φ600mm, and the height to be 1800mm;

[0153] Step 2: Ingot Quality Inspection:

[0154] The state of the ingot is annealed, and the quality of the ingot is being controlled;

[0155] Step 3: Heating the ingot before forging:

[0156] The ingot is installed in the furnace at room temperature. The heating process is divided into two stages. The first stage: from room temperature to 450°C for 2 hours, and keep it for 1 hour; the seco...

Embodiment 3

[0194] Taking the 2A14 aluminum alloy tubular forging, a key part of a key model of the Air Force, as an example, the finished product size is Φ1040×Φ870×1000mm, including the following steps:

[0195] Step 1: Raw material size design:

[0196] The aluminum alloy round ingot produced by the semi-continuous casting method as the raw material, considering the structural size of the part, the consumption of the forging process, and the machining allowance, requires the height-to-diameter ratio of the ingot to be L / D=2.5, the diameter of the ingot to be Φ600mm, and the height to be 1500mm;

[0197] Step 2: Ingot Quality Inspection:

[0198] The state of the ingot is annealed, and the quality of the ingot is being controlled;

[0199] Step 3: Heating the ingot before forging:

[0200] The ingot is installed in the furnace at room temperature. The heating process is divided into two stages. The first stage: from room temperature to 440°C for 2 hours, and keep it for 1 hour; the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com