Oil waste gas treating device

A waste gas treatment device and technology of a treatment device, applied in the direction of electrostatic effect separation, solid separation, and dispersed particle separation, etc., can solve the problems of low waste gas treatment efficiency, high concentration, blockage of oil waste gas treatment device, etc., to improve treatment efficiency and benefit , Improve processing efficiency, improve the effect of maintenance or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

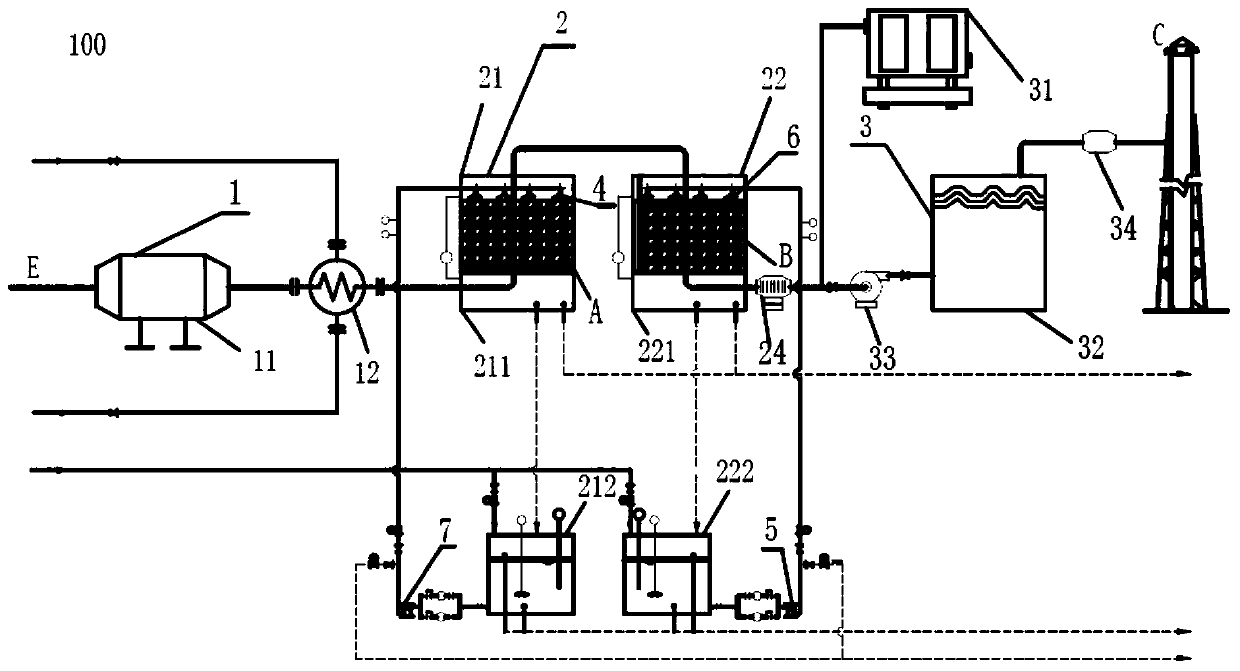

[0024] figure 1 It is a schematic structural diagram of a grease waste gas treatment device 100 according to the present invention. The device 100 includes: a primary processing device 1, the primary processing device 1 includes an electrostatic degreaser 11 and a heat exchanger 12 connected in sequence, a secondary processing device 2, and the secondary processing device includes a sequentially connected heat exchanger 12 The connected biological scrubbing device 21 and the biological trickling filter device 22 , the tertiary treatment device 3 , the tertiary treatment device 3 includes an ozone reaction device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com