A processing method of high-moisture non-fried flavor fish that can be stored at room temperature

A processing method and high-moisture technology, which can be used in heating preservation of meat/fish, chemical preservation of meat/fish, food science, etc. The effect of simplifying product texture impact, reducing sterilization intensity, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Kill the fresh grass carp by knocking the head, remove the head, remove the tail, remove the internal organs, cut open the back, remove the main bone spurs, wash the residual internal organs and congestion with water, drain, and cut the fish body into 20~ 30g fish pieces;

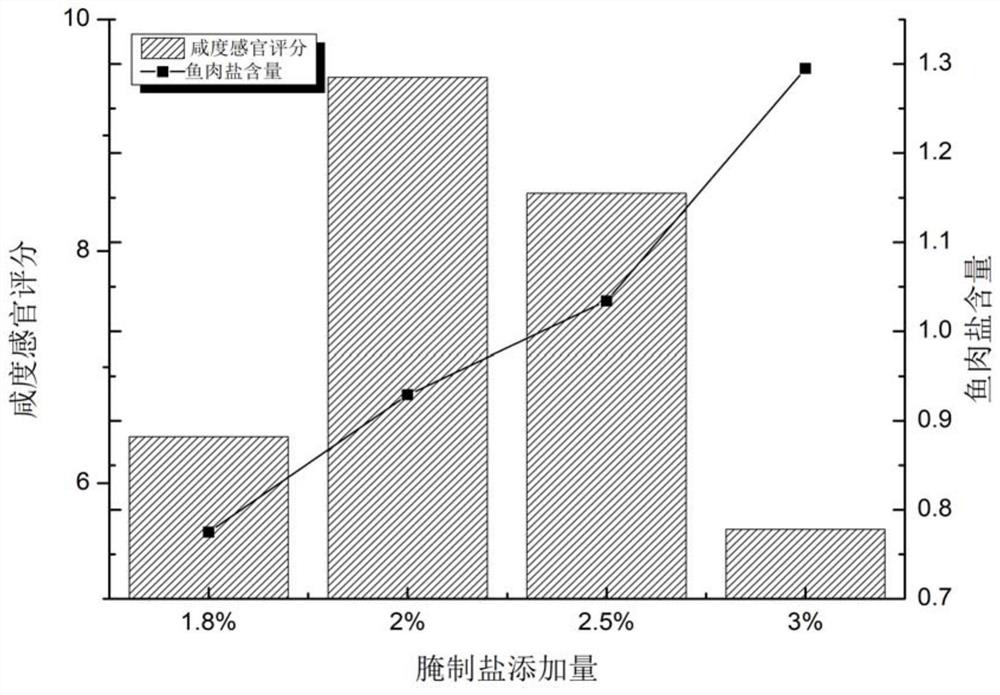

[0031] (2) Pickling: add edible salt that accounts for 2% of the mass of the fish pieces to the drained fish pieces, mix well and marinate at 4°C for 2 hours, and add 5% of the mass of the fish pieces. After marinating at 4°C for 10 hours, rinse with water and drain;

[0032] (3) Drying at low temperature: drying the drained fish pieces at a temperature of 12° C. and a wind speed of 2 to 4 m / s until the water content of the fish pieces is 65%;

[0033] (4) Seasonings: Based on the mass percentage of fish pieces, add 3% ginger granules, 3% clear oil, 0.5% thirteen incense, 0.5% salt, 1.7% chili powder, 1% red yeast rice powder, mix with fish pieces;

[0034] (5) Vacuum packaging: the fish piece...

Embodiment 2

[0037] (1) Kill the fresh grass carp by knocking the head, remove the head, remove the tail, remove the internal organs, cut open the back, remove the main bone spurs, wash the residual internal organs and congestion with water, drain, and cut the fish body into 20~ 30g fish pieces;

[0038] (2) Pickling: Add 1.5% edible salt to the drained fish pieces by weight, mix well, marinate at 4°C for 1.5 hours, and add 5% by weight of fish pieces. After marinating at 4°C for 10 hours, rinse with water and drain;

[0039](3) Drying at low temperature: drying the drained fish pieces at a temperature of 12° C. and a wind speed of 2 to 4 m / s until the water content of the fish pieces is 65%;

[0040] (4) Seasoning: In terms of the mass percentage of fish pieces, add 2% ginger granules, 2% clear oil, 0.5% thirteen incense, 0.5% salt, 1.3% chili powder, 1% red yeast rice powder, mix with fish pieces;

[0041] (5) Vacuum packaging: the fish pieces that have been mixed with the ingredients...

Embodiment 3

[0044] (1) Kill the fresh grass carp by knocking the head, remove the head, remove the tail, remove the internal organs, cut open the back, remove the main bone spurs, wash the residual internal organs and congestion with water, drain, and cut the fish body into 20~ 30g fish pieces;

[0045] (2) Pickling: add edible salt that accounts for 2% of the mass of the fish pieces to the drained fish pieces, mix well and marinate at 4°C for 3 hours, and add 5% of the mass of the fish pieces. After marinating at 4°C for 15 hours, rinse with water and drain;

[0046] (3) Drying at low temperature: drying the drained fish pieces at a temperature of 12° C. and a wind speed of 2 to 4 m / s until the water content of the fish pieces is 65%;

[0047] (4) Seasonings: Based on the mass percentage of fish pieces, add 3% ginger granules, 3% clear oil, 0.7% thirteen incense, 0.7% salt, 1.7% chili powder, 1% red yeast rice powder, mix with fish pieces;

[0048] (5) Vacuum packaging: the fish piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com