Injection molding inductor and manufacturing method thereof

An injection molding, inductance technology, used in the manufacture of inductors/transformers/magnets, transformer/inductor shells, signal inductors without magnetic cores, etc. Backing, poor high-frequency characteristics of inductance components, etc., to achieve the effect of simplifying packaging, structure and manufacturing process, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

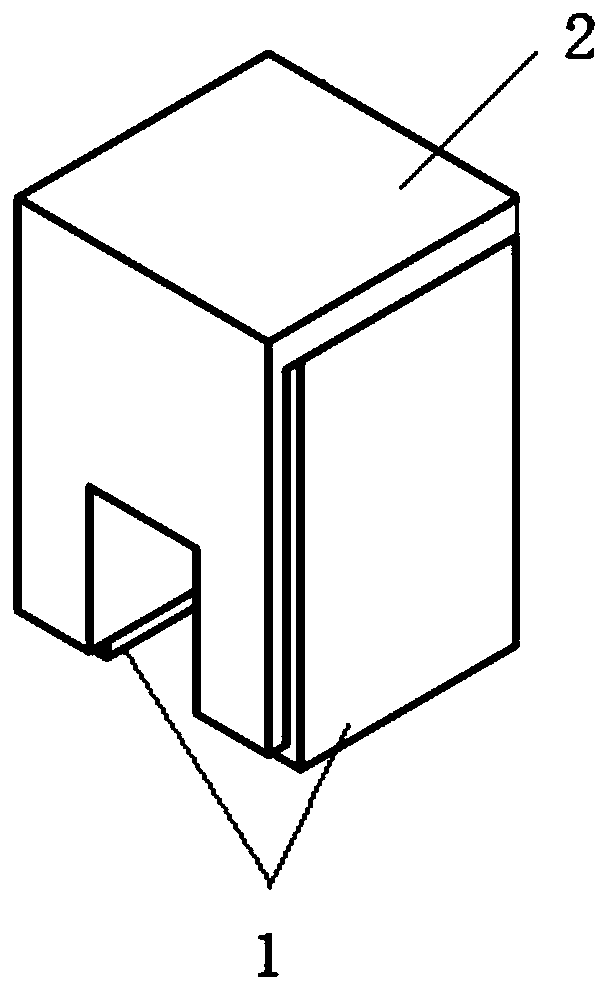

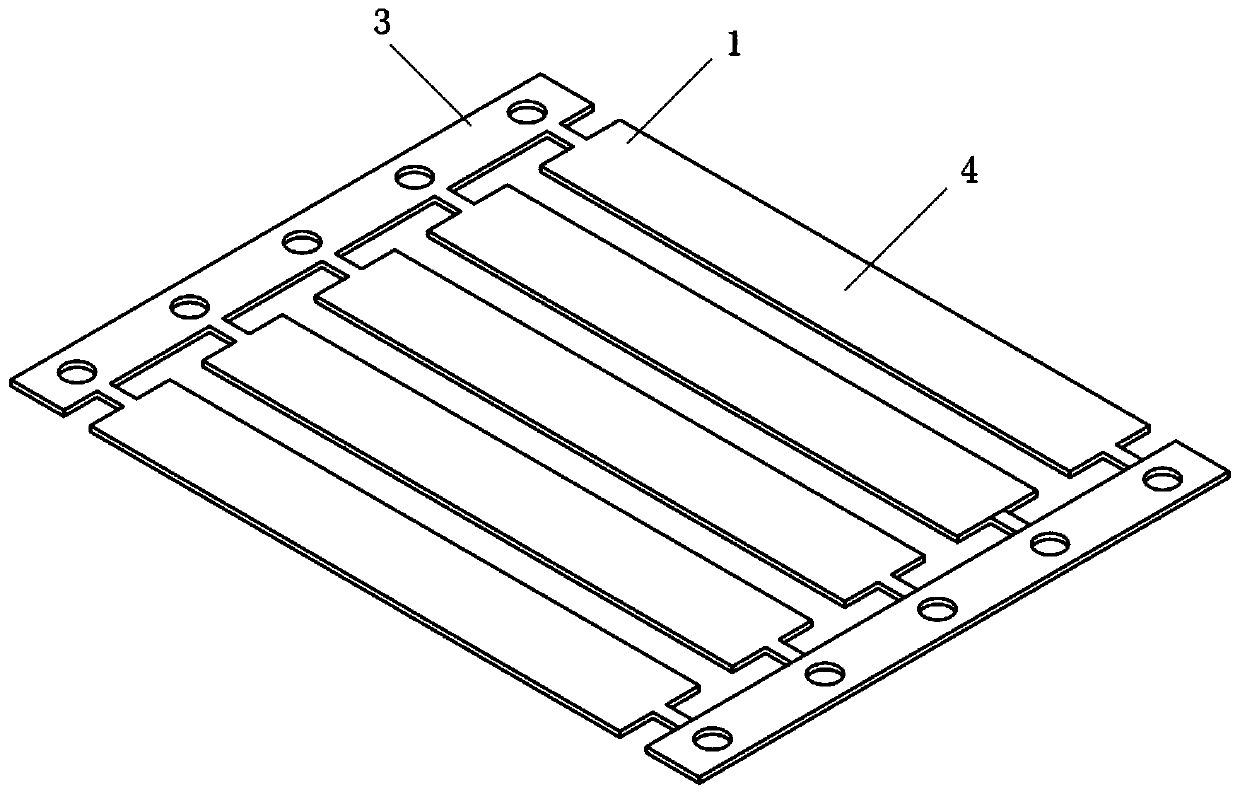

[0061] A small size and low back injection molding inductor suitable for high frequency and high current, reference figure 1 , Figure 3 to Figure 7 . The injection molded inductor includes a copper wire, an electrode, a coil (single turn) and a cladding layer; the copper wire, electrode, and coil are an integral structure before injection molding and are presented in the form of a strip; the copper wire is A flat wire, the two ends of the copper wire are bent to form inductance electrodes; the middle section of the copper wire and the electrodes at both ends form a single-turn coil; the coating layer is made of a polymer insulating material.

[0062] In this specific embodiment, the aforementioned material strip enters the injection molding mold cavity through the assembly line, and the molding coating layer is injected, and then enters the stamping progressive die station through the assembly line to complete the cutting, primary bending, and secondary bending in sequence. Bend...

Embodiment 2

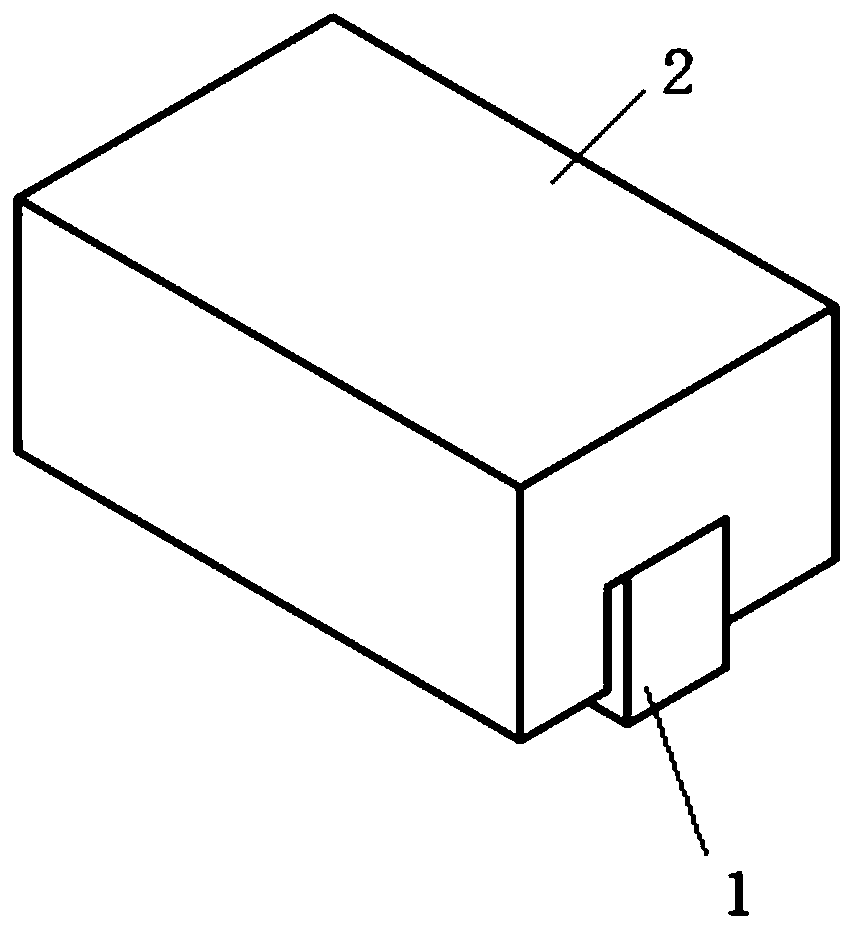

[0064] A small size and low back injection molding inductor suitable for high frequency and high current, reference figure 2 , Figure 8 to Figure 12 . The injection molded inductor includes a copper wire, an electrode, a coil (multi-turn), and a coating layer; the copper wire, electrode, and coil are an integrated structure before injection molding and are presented in the form of a strip; the copper wire is The two ends of the copper wire are bent to form an inductive electrode; the middle section of the copper wire is spot-welded with a flat wire vertical winding multi-turn coil; the coating layer is made of a polymer insulating material.

[0065] In this specific embodiment, the aforementioned material strip enters the injection molding mold cavity through the assembly line, and the molding coating layer is injected, after the magnetic core glue is baked and cured, and then enters the stamping progressive die station through the assembly line to complete the cutting in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com